Today we’ll talk about such a popular building material as corrugated board. About its advantages and disadvantages, where it is used, and the technology of installation on roofs. After reading the article, you will not need to look for information in other sources. But the main emphasis here will be on information about corrugated roofing.

What is corrugated sheeting

This is a galvanized steel sheet with a thickness of 0.35 to 1.2 mm, which is formed by cold rolling into a wave-like material. It is in this way that the load-bearing capacity of sheets is increased. In this case, the shape of the corrugation can be wavy or trapezoidal.

Corrugated sheeting is made only from galvanized steel, which has high moisture-proof properties that resist metal corrosion processes, plus increase the service life of the material. Today, manufacturers offer painted profiled sheets or coated with a polymer layer. This, firstly, further increases the service life of the profiled sheets, and secondly, it becomes possible to select a coating with a specific color design.

Main parameters of corrugated sheets:

sheet thickness;

profile height;

profile width;

working width of the material itself.

Dimensions of profiled sheet Source proftehnastil.ru

Advantages and disadvantages

Let us outline the advantages of the material:

small specific gravity, which facilitates operations carried out with it;

simple installation process;

low price compared to other roofing coverings;

variety of colors;

aesthetic appearance of the roof.

As for the cons:

corrugated sheeting is a metal product, so it has high thermal conductivity, which requires roof insulation;

low sound insulation.

On our website you can find contacts of construction companies that offer roof design and repair services. You can communicate directly with representatives by visiting the “Low-Rise Country” exhibition of houses.

Criteria for choosing corrugated roofing

The construction of a roof from corrugated sheets begins with the selection of the roofing material itself. Today, manufacturers offer three types of profiled sheets:

The marking “H” indicates a load-bearing type used specifically for roofing.

Wall models are produced with the “C” marking, which are most often used for the construction of fencing structures and cladding of wall and ceiling surfaces. Although we must pay tribute to the fact that corrugated wall sheets are also used for the construction of roofs of light canopies, terraces and gazebos.

“NS” is a universal type used in any building structures, and on roofs as well.

That is, it turns out that any of the above varieties can be used to cover roofs. But there is one important nuance here. If you want a roof built from corrugated sheeting to last a long time and withstand serious loads, then you need to choose a material with a metal sheet thickness of at least 0.55 mm.

Please note that this is the thickness of the metal, which does not include paint or a polymer layer. And if in the store you take a measurement with a caliper and it is 0.55 mm, then know that the actual thickness will be 0.5. Please also note that this size is not indicated separately in the certificate of conformity. It is indicated on the product labeling. For example, H75-750-0.9. “0.9” is the thickness of the metal.

As for the profile dimensions (height and width), the larger they are, the higher the load-bearing capacity of the material. But at the same time, the overall dimensions of the profiled sheets are reduced. This means that it will be necessary to purchase more roof covering elements. For example, corrugated sheeting grade N75-750, where 750 is the width of the sheet. Or C40-1000, where 1000 is the width. That is, the load-bearing capacity of the roofing material increases, while the area of the coating itself decreases.

Rules and nuances of installing profiled sheets on the roof

Installation of a corrugated roofing begins with the acquisition of the required amount of material. For example, if it covers a gable roof, then you need to measure the width of the slope and divide it by the working width of the sheet. This is the quantity per slope. In this case, the length of the profiled sheets is not taken into account, because they are produced either six or twelve meters long. In this case, the store will cut the panels to the required length dimensions in 50 cm increments, starting from 0.5 m and more.

This is another great advantage of the technology of covering the roof with corrugated sheets. It ensures minimal waste. And if you correctly measure the length of the slope, then the roof covering will be without joints. The latter are places of possible leaks if you incorrectly take into account the angle of inclination of the slope and the size of the overlap of two adjacent elements.

We move on to installing a roof from corrugated sheets over wooden sheathing.

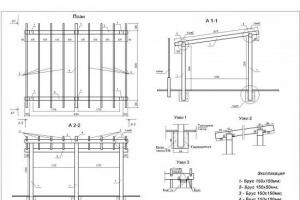

Lathing for corrugated sheets

For this, edged boards with a thickness of 25-35 mm and a width of 100 mm are used. The main design parameter is the distance between elements. It is determined by the size of the corrugated sheet itself. The greater its load-bearing capacity, the greater the distance in the construction of the sheathing. For example, for profiled sheet H75 the distance between the boards is 1.5-2 m, for C40 the distance is 0.5-0.6 m.

Video description

The process of assembling the sheathing for corrugated sheets in the video:

Roof covering

First of all, the roofing material must be lifted onto the roof. If the house is one-story, then the easiest way is to install two bars or two boards 50 mm thick with a distance between them less than the width of the corrugated board. The photo below shows how to install the boards.

Raising is done like this:

a through hole is made in one sheet near the edge in the middle;

it is laid on boards so that the hole is at the very bottom;

You can put a couple more sheets on top;

a hook tied to a rope is inserted into the hole;

They pull the rope from the side of the roof, and push it up with their hands from below.

The installation itself is carried out on either side of the slope. The main task of the work manufacturer is to align the sheets exactly along the cornice, that is, horizontally. Therefore, it is important to accurately align the first sheet to be fixed. Fastening is done using roofing screws with a wide head. In this case, the screws are not screwed in completely, leaving the opportunity to once again check the accuracy of the corrugated sheet installation. And if everything is correct, then tighten the fasteners until the end.

The sheets themselves are laid overlapping with an offset in one wave. This ensures reliable closure of the joint between the elements, which ensures that there are no leaks.

Option for lifting profiled sheets onto the roof Source angara32.ru

Roof covering with separate sheets

If the installation of a roof made of corrugated sheets is made in short sheets (less than the length of the slopes), then it is important to carry out the installation correctly in terms of choosing the overlap of the sheets in the longitudinal direction. This parameter depends on the angle of inclination of the slopes. Here the dependency is:

tilt 5-10°, overlap 30 cm;

tilt 10-15°, overlap 20 cm;

tilt more than 15°, overlap 17 cm.

Fastening rules

The rules for covering a roof with corrugated sheeting include items related to the correct fastening of sheets to the sheathing.

Attaching to the sheathing is done through the lower wave.

The fastening of two sheets in a transverse overlap is carried out in the upper wave.

The screws are screwed in strictly perpendicular to the plane of the roof slope.

You must not over-press the fastener or under-press it, because in the first case this will lead to a break in the gasket, and in the second to its loose pressing. Both reasons are the appearance of leaks in the place where screws are attached to profiled sheets, which will lead to leaks.

Places of fastening - along the upper and lower edges of the sheet through a wave, intermediate fastening over the entire remaining area through 2-3 waves for each element of the sheathing.

Installation and fastening of additional elements

Additional elements for the roof made of profiled sheets include ridge and gable strips. The eaves strips are installed before the installation of the corrugated sheeting begins, and they are attached to the rafter legs or the first lower element of the sheathing.

The ridge is closed with a special element, which is attached to the sheathing through laid corrugated sheets. The fastening is made through the upper wave of the roofing material. The fastening pitch is 20-30 cm. The length of the ridge element is 3 m, so they are installed overlapping each other with an offset of 10-15 cm.

Gable strips are installed for one purpose - to protect the roofing from the wind, so that it cannot penetrate under the corrugated sheeting and not penetrate it with its force. Plus, the aesthetic side of the matter and the completeness of the roofing structure are ensured. The gable strips are attached to the profiled sheets in the upper outer wave. If there is a gable beam in the roof structure, then the same applies to it.

The standard length of the planks is 3 m, they are laid overlapping with an offset of 10 cm. The fastening spacing with self-tapping screws is 30-40 cm.

When choosing corrugated sheeting for roof construction, you need to choose it correctly according to the type of polymer layer applied. Manufacturers offer several polymers that cover profiled sheets.

The thicker the protective polymer layer, the higher the price of corrugated sheeting. It is necessary to take into account that expensive roofing material must be used wisely. It has good technical characteristics, especially wear resistance and resistance to ultraviolet rays. Therefore, it is recommended to use this material in areas with active loads. For example, with the negative impact of air with a high concentration of salt (coastal areas), with an increased concentration of acids and other active substances in the air (large industrial cities).

Online roofing calculator

To find out the approximate cost of different types of roofing, use the following calculator:

Video description

Installation of corrugated sheeting on the roof:

Conclusion

The correct choice of corrugated sheeting used as a roofing material, plus its proper installation, guarantees long-term operation of the roof. In addition to the economic side of the matter, you need to correctly calculate the required amount of roofing.

Recently, builders are increasingly choosing corrugated sheeting as a roofing material. It is important to install a strong and reliable sheathing underneath, which will guarantee the durability of the roof. But this is what determines how warm and comfortable the house will be on the coldest days. After completion of the work, you will receive a system that will protect the building from the effects of fungi, bacteria, as well as external negative factors, keeping the building in its original form for a long time. This material is very easy to install, which is why private craftsmen carry out all manipulations themselves, refusing expensive professional help. After studying the technology, you can evaluate your strengths.

Before work

Installing corrugated sheets, as practice shows, is a fairly simple task. However, it is important to comply with standards and technologies. Before laying this material, you must correctly install the beams, mount the rafter system and frame structure. Metal or wooden elements are laid on the base, which protrude 0.5 meters beyond the walls. As a basis for the roof, you should use a rafter system, which consists of vertical posts, inclined struts and legs on inclined rafters.

The installation of a roof made of corrugated sheets over a wooden sheathing requires the installation of rafters, the distance between which can vary from 60 to 80 centimeters. It is important to take into account the load on elements at a certain angle. To make rafters, you should use dry coniferous wood, which will avoid deformation of the entire structure.

In places where the volume of snowfall is increased, the angle of the rafters should be from 35 to 45 degrees. In areas where weather conditions are moderate, an angle of 20 degrees should be made. The installation of a roof made of corrugated sheets over a wooden sheathing involves the creation of a special structure that will act as a frame for the covering material. To do this, use wooden beams.

Types of sheathing

If we are talking about industrial buildings, then in this case metal frames are most often used. When constructing private houses, wooden sheathing is used, the elements of which are treated with an antiseptic. To do this, you should use boards with a cross section of 25-30x100 mm. The framing system must be installed after laying the waterproofing layer. It will absorb moisture from the insulation side and prevent the penetration of condensation that forms on the lower surface of the roofing sheet due to temperature fluctuations.

Classification of sheathing

The installation of a roof made of corrugated sheets over a wooden sheathing may involve the installation of elements with a regular pitch; for this, a distance between bars or boards is maintained in the range of 20 to 40 centimeters. This type of construction is most often used in tandem with corrugated sheets. The lathing can also be continuous, with a gap of 10 millimeters between the boards to prevent damage due to swelling or drying out of the boards. Sometimes plywood or moisture-proof chipboard is used for this. The sparse lathing is arranged with a step between elements ranging from 50 to 75 cm.

The construction of a roof made of corrugated sheets over a wooden sheathing can be carried out only after you choose the type of frame. It will depend on the brand of covering material used, as well as For example, if the angle is 15 degrees, then a continuous sheathing should be used for C10 grade corrugated sheeting. Whereas C21 corrugated board requires conventional sheathing, the distance between the elements of which is 300 millimeters. If you purchased C44 material, then you will need to arrange a sparse sheathing, the distance between the bars varies from 500 to 1000 millimeters.

They can also be produced using a two-layer sheathing, which is required to ensure high roof strength and impressive loads on it. In the bottom row, a sparse installation of components is performed, while in the top row the system can be continuous or have a regular step. The bottom row is formed parallel to the ridge, and the top row should be located perpendicular to this component of the structure.

A special case

A two-layer frame system is necessary when laying thick thermal insulation, the thickness of which can reach 100 millimeters. In this case, two bars are reinforced across the rafters, each measuring 50x50 millimeters. Installing a roof when forming a conventional sheathing involves the use of wooden beams, the cross-section of which can vary from 50x50 to 75x75 millimeters. A regular frame is sometimes made of boards whose width does not exceed 150 millimeters. Whereas the thickness can be 20-50 millimeters. It is very important to limit the width of the board to 15 centimeters, otherwise the wood will be deformed from exposure to dampness and temperature changes.

Fasteners

The sheathing under the roof can be fixed using nails or self-tapping screws. The length of the fasteners should be equal to double the thickness of the sheathing. If a square beam with a side of 50 millimeters is used, then the fastening elements must have a length of 100 millimeters. Frame elements are fixed to each roof rafter. Boards and beams should not have defects or protruding knots.

Technology for installing a frame system on a rafter roof

If the rafter roof will be covered with corrugated sheeting, then the location of the boards and beams must be marked outside. This is done on the outermost rafters. Along the entire slope you need to measure the places where the timber or board is fixed. If a protrusion into a recess is found at its location, then it is necessary to get rid of them by cutting off the material or stuffing the slats. You can use roofing felt for this.

The sheathing is laid from the ridge. The distance between elements should be from 20 to 40 centimeters. Wooden boards are spliced along their length, since the standard length of lumber is shorter compared to the length of the slope. To do this, the edges of the pieces must be secured with nails, and then installed on the roof so that the joint of the beam fits the rafters. In each horizontal row, the joints should be offset. To do this, the boards are cut to the required length.

Wind boards must be installed at the ends of the roof; their height is greater than the sheathing by an amount that is equivalent to the height of the profile of the covering material. When the rafters and sheathing are ready, you can proceed to installing the corrugated sheet, which is reinforced with self-tapping screws; their top coating should be made of zinc. Rubber washers can be used as a gasket. You will need 5 fasteners per square meter of covering material. The corrugated sheets are connected to each other using rivets.

Nuances of the work

Having determined the dimensions of the roof, you can calculate how much material will be needed for the work. When you visit the store, you will find that the sheets are usable and full width. Depending on these numbers, calculations can be made. First, the roof area is determined, and then the useful area of one sheet. Then the first value must be divided by the second, this will allow you to understand how much material you need to purchase. When purchasing, you must remember that a high profile height will be able to provide the surface with the ability to endure heavy loads. If we are talking about a private house, then it is best to use corrugated sheeting of 35 millimeters, its thickness should be approximately 0.6-0.7 millimeters. Roofing work with corrugated sheeting of a smaller profile height is carried out taking into account the installation of sheathing, between the elements of which a smaller step must be ensured. This will allow for greater rigidity and high structural strength.

If different parapets and chimneys will pass through the roof, separate sheathing should be installed under them. For the chimney, it is located with a deviation of 15 centimeters. You cannot start work during rain, as the boards may get wet, which will lead to their deformation when drying.

Fastening corrugated sheets

The corrugated sheet for the roof begins to be installed from the lower corner of one of the ends. If several rows are to be installed, then the material is installed in the bottom row with some overhang of the plank from the eaves, which is about 40 millimeters. The sheet is fixed to the last plank at the edge of the roof along the bottom of every second wave. On the sides of the building, the end boards are sewn up with wind corners; this will have to be done after the entire end row has been secured. The overlap of the sheets should include an overlap of 200 millimeters in the vertical direction. In a horizontal sheet, the top sheet overlaps the bottom sheet by a wavelength. This is true when used. If you decide to carry out work without it, then the approach in the horizontal direction should be two wavelengths.

The corrugated sheet for the roof must be strengthened using a certain technology. As soon as the main sheet can be fixed, you can begin installing the ridge and end strips. In the first case, the elements are not compacted, and gaps should be left in the profile relief, which will ensure ventilation of the under-roof space. The final stage is the installation of connections to the walls of buildings located nearby.

Price

Profiled sheets, the price of which is quite reasonable, are considered a common material today. For a square meter of profiled sheet C21 you will have to pay 174 rubles, while the thickness will be 0.4 millimeters. Corrugated sheet C10 costs 154 rubles. per square meter, the thickness remains the same. It is important to remember about consumables, for example, a roofing screw will cost 2 rubles. a piece. If you decide to use corrugated sheets for roofing work, the price of this material should interest you. Once you know it, you can compare it with the cost of other materials. Sometimes this allows you to make the right choice.

It is quite easy to build a high-quality and durable roof from corrugated sheets yourself. It is only important to know what materials you need to take, how to properly attach the sheets to the sheathing and how to protect the internal under-roof space from dampness.

And we will pay special attention to additional elements that need to be bypassed in full compliance with technology. So, do your own corrugated roofing - step by step!

Preparing material: avoiding first mistakes

Once you have made accurate calculations for your roof, you can order profiled sheets. But, if you purchased corrugated sheeting, but for some reason its installation will have to be postponed (for example, prolonged rains), then store the sheets without removing the original packaging, on a flat surface and indoors. Additionally, beams must be placed under the sheets in increments of 50 cm.

Shift and move such roofing material carefully, holding the edges along the length and especially avoiding creases and deflections of the sheets. You also need to move the sheets carefully, because... modern polymer coating is especially sensitive to mechanical damage.

How to cut this material with abrasive cutting tools: fragments from the wheel will scratch, and significant heating will occur at the cutting site. But, if you had to work this way, then immediately cover all the damage with repair paint.

Fortunately, the technology for constructing a roof made from modern corrugated sheets will allow all work to be carried out in the warm season, from April to September, and you will not have to store the sheets for a long time.

Installation of corrugated sheeting: step-by-step master classes

Let's first of all immediately understand the construction terms so that you don't have to look on the Internet for the meaning of each new word:

You will be surprised, but the same (at first glance) material needs to be laid in different ways. It's all about the manufacturers - everyone gives their own recommendations for installation, and they are really important. Because corrugated sheets from different companies are demanding in terms of their conditions, even if the differences are small. Therefore, carefully study the instructions supplied with the roofing material and do not completely trust hired workers who “have eaten the dog on such roofs” and are trying to do everything their own way.

Here is a simple example of how the installation of corrugated sheeting with a thickness of less than 0.7 cm and more durable differs:

And when working with such material, a wooden scaffold is no longer needed:

Imagine that the hired team will trample their feet on thin corrugated sheeting, because before that they “installed exactly the same roof for your neighbor” and “nothing was bent”? And now it will bend, and how, to which the would-be workers will declare that “that’s how it was.”

But, speaking in general, the main indicator of high-quality roof installation is tightness. After all, the roof serves precisely this purpose, so that all internal structures are protected from moisture and cold. And even an inconspicuous gap can become a serious problem: dampness, smudges, quickly deteriorating materials and fungus. That is why we will now analyze in detail all the subtle points.

A little about safety

The technology of metal roofing itself is not so complicated, but it is important not to damage the roofing covering during its installation. After all, although this material looks durable and tough, you still need to be careful when working with it:

- Walk on the finished metal profile flooring in soft shoes.

- Try to step only on the concave waves of the sheets and preferably directly on the screws.

- So, you can only step on your toes on the roof.

- Always place your foot parallel to the slope.

- There should only be one leg in one notch.

Construction of sheathing for corrugated sheets

The lathing for roof installation is either continuous, if the slope is small, or sparse, in increments of up to 5 meters. But with what step the roof sheathing is needed depends on how thick the corrugated sheets are:

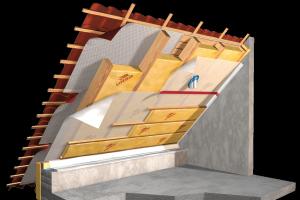

Waterproofing and windproofing

Next, we think about how to properly make a roof pie. The modern market produces many waterproofing materials of various types and properties. We even have a whole separate article about this. But in general, focus on the following program of action:

- Step 1. So, secure the selected waterproofing material to the rafters. To do this, take the most ordinary construction stapler, but before installation, be sure to check whether you are laying the film or membrane on the wrong side. And glue the panels together with a special tape.

- Step 2. After this, we punch slats along the rafters (take a thickness of at least 2 cm) and thus form the ventilation gap necessary for ventilation.

- Step 3. Now we lay the roofing material along this top sheathing.

Here's what it all looks like in real life:

We select high-quality screws

The consumption of self-tapping screws when attaching corrugated sheets is usually about 6 pieces per 1 square meter. Suitable screws are 4.8 by 28-35 mm, as for wood, and for additional elements - 4.8 by 50 or 60 mm. As a tool, purchase a screwdriver with a special attachment or a cordless electric drill from the same manufacturers of roofing materials.

Special self-tapping screws for fastening corrugated sheets are indispensable, because... This is the only way to ensure:

- Fully waterproof roof.

- High connection strength.

- Minimal risk of injury to the coating during fastening, which means no corrosion in the future.

The highest quality and most reliable self-tapping screws for corrugated sheets are sold by the same suppliers that deal with sheets. If possible, use carbon or stainless steel screws with a zinc coating - these are ideal. But when purchasing, still carefully inspect all sealing washers.

How to properly attach corrugated sheets?

You can tell that you have secured the screw correctly by the metal washer - about 1 mm of the rubber gasket will protrude from it.

Screws must be screwed into the roofing material strictly perpendicularly, directly into the deflection of the vertical wave near the corrugated sheeting. Although there is a lot of controversy about this in the construction community, and each method has its own advantages. Thus, a self-tapping screw in the lower wave creates a more reliable fastening, and in the upper wave, rainwater has much less chance of getting into the under-roof space.

At the eave and ridge, you need to drive screws into the camber through the wave, and in the middle of the sheet into each sheathing board. In total you will need about 5-8 pieces per square meter.

What tools will be needed for installation?

Note that the construction of the roof itself from corrugated sheets is really within the power of even a person with little knowledge of construction. Of course, there are roofing materials that only experienced professionals can install correctly. But in the case of modern corrugated sheeting, we can reassure you: you can handle it yourself!

Fortunately, there is nothing complicated here. Thanks to the long length of the sheets, the roof slopes overlap without additional transverse joints, and the material itself can be easily cut and adjusted in shape. You will need a minimum of tools for this task:

So, corrugated sheeting can be laid on slopes of almost any inclination angle; it is only important to correctly calculate the amount of transverse overlap:

- 150-200 mm for roofs with 15-30°.

- 200 mm for a slope of 14°.

- 100-150° at large angles.

For fastening you will need self-tapping screws with special sealing washers:

In what order should the sheets be laid?

Many roofers install corrugated sheets this way: starting from the bottom row, first lay 4-5 sheets, and each of them is fixed with only one screw in the center. After this, the sheets are connected to each other with 4.8x19 mm self-tapping screws, which are installed in increments of 500 mm. Now they check how aligned the sheets are with the roof overhang, and finally fix the roofing material. Here's the scheme:

But, if you are working on the roof for the first time, to avoid distortion, attach the corrugated sheets according to the same pattern, but in this order:

- Step 1. Install the first sheet on the sheathing, and fasten it with one screw at the very ridge.

- Step 2. We lay the second sheet so that the lower edges of both sheets below form one perfectly straight line.

- Step 3. We fix the overlap along the top of the wave under the very first transverse fold.

- Step 4. We evaluate by eye how correctly the sheets are joined. Uneven? Then lift one sheet from the other, tilt it slightly from bottom to top, and again join fold by fold. Secure everything with self-tapping screws along the top of the waves.

- Step 5. So work with 3-4 sheets, carefully align them with the cornice and then install the remaining sheets.

The corrugated sheeting must be mounted to the base of the roof so that the edge offset is 40 mm from the eaves. This is necessary in order to leave a gap of optimal size on the ridge and the ventilation of the roof is not impaired. By the way, if the profiled sheets have a drainage groove, then each subsequent one should overlap the groove of the previous one.

Remember: when laying, you cannot step on the ridge of the sheets - they will bend. In general, for such work, installers wear soft shoes. That's all the subtleties!

Working with additional elements

Now let’s move on to our numerous additional elements. All of them, as a rule, are made in standard lengths: for polymer-coated roofing - 2 meters, for galvanized roofing - 2.5 meters. They complete the roofing work itself. The seal, which is traditionally placed between the roofing material and additional elements, allows them to fit more tightly to the sheets, further preventing moisture from entering under the roof and allowing it to “breathe.”

But to decorate ridges, cornices and other complex structures, you need to purchase special elements that are offered by the same manufacturer whose roofing material you purchased:

The additional elements must be fastened with the same 4.8 roofing screws as the base material. The only difference is that the metal roof is fastened with self-tapping screws 28-35 mm long, and the elements are fastened with self-tapping screws 50-60 mm long.

Valley and valley overlay

Now let’s look at such a mysterious name as “endova”. The valley and valley overlay are additional elements that duplicate each other, which are mounted at the internal convergence points of two differently directed slopes. The valley must be secured under the corrugated sheet.

Therefore, if the roof has a complex shape, with internal surface joints, then take a valley and a valley overlay as an additional element. This way you will give your roof a more neat and aesthetic appearance, additionally protecting complex transitions from moisture getting inside.

Aprons for pipes

The most critical stage of the roof is the removal of pipes. Such pipes consist of two conventional parts - the lower one, which runs along the roof profile, and the upper one, the pipe itself. And, if the through passage of the pipe is on the lower part of the roof, it makes sense to install a snow block above the passage.

For a sewer ventilation system, an uninsulated pipe of about 10 cm in diameter, without a head, is passed through the roof. And for radon they take the same pipe, but with a head. Remember that these pipes cannot be connected to ordinary ventilation pipes, because... for those, insulated elements with a diameter of 125 mm are already used.

The pipe itself can be installed both before the installation of the roof begins and after completion. If you chose the second option, then you will need to cut a hole in the finished roof for the pipe and temporarily cover it with some material. During the finishing work, pipe cuttings will need to be made from galvanized steel aprons or more modern materials like Wakaflex.

Here's a good tutorial on how to do it:

Dormer window

Now we are working with the dormer window. So, we cut the corrugated sheet into two parts at the lower end of the gutter, install the bottom sheet, then the bottom gutter strip, and only then the top roofing sheet.

Snow holder

The snow holder is mounted in places where there is a risk of snow rolling down. For corrugated sheeting, this is usually the second line at a distance of 30-40 cm from the eaves. For installation, use 4.8x50 self-tapping screws through 1-2 waves of the profile.

External and internal corner

If the slope changes its direction, then additional finishing elements such as internal and external corners and transition are used. Their main task is to create maximum tightness and give the joint of sheets an aesthetic appearance.

Adjacency

An abutment is an additional element that serves as a rim for a chimney or to protect the junction of the roof and the wall:

Cornice, end and joint strips

And here are your instructions:

- Install the end strips from the side of the roof overhang, towards the ridge.

- Just cut off the excess part of the end strip.

- Secure the plank to the end board and the corrugated sheets in the ridge with screws in increments of up to 1 meter. If you did everything correctly, the end strip will cover at least one wave of the roofing profile.

- Attach the end strip with wood screws 4.8x60 or 4.8x50, directly to the wooden base. Leave the step from 30 to 50 cm and make sure that the end strip completely covers the end of the outer wave of corrugated board.

Now we proceed to the installation of the joint connecting strip. Its length is 2 m, and the overlap of the planks cannot be less than 1 meter. The joint strip is taken 2 meters long, and the two strips are attached to each other with an overlap of at least 1 meter. The additional element should be attached to the wall in a groove, or hide everything under the wall sheathing.

The main purpose of the eaves strip is to protect the under-roof space from precipitation, especially in rain with strong winds. And the lower the roof slope, the more necessary this additional element is. But you need to attach the cornice strip before the corrugated sheets. Overlap – 100 mm.

Ridge installation

After all the roofing material has been laid, we attach the ridge. We line the junction of the ridge and the roof with a sealant in advance. Ridge elements for trapezoidal roofing sheets are usually smooth. It is advisable to place ventilated seals between them and the profiled sheets, and for small corrugations - special ridge seals.

We fasten the ridge with self-tapping screws on both sides at a distance of 2-3 waves. It is important that the ridge itself covers all the first screws that hold the sheets of roofing material. The ridge strips must overlap each other with an overlap of at least 1 meter, and we fasten the elements to the roofing sheets with self-drilling screws in increments of up to 3 meters.

An important point: the smaller the angle of inclination of the roof, the wider the ridge itself should be. So, the most standard sizes are 140x140 mm or 200x200 mm.

But today it is more fashionable and rational to order a figured skate, which comes in two parameters: 110x30x110 mm and 145x50x145 mm. There are also special types of ridge for complex roofing, when multidirectional slopes come together.

Maintenance of corrugated roofing

Snow on a roof made of corrugated sheets lingers quite a bit, and therefore there is no need to clean it. But, if you need to carry out certain repairs, then arm yourself with small plastic shovels that will not leave scratches.

Caring for a roof made of corrugated sheets is quite simple: the rain itself will wash away all the dirt and dust, and you only have to clean the gutters and drainage systems from clogged fallen leaves once a year.

If for some reason more serious cleaning is necessary, then use ordinary water and a hose with a pressure of up to 50 bar. Detergents can only be used that are intended for painted surfaces, and “White spirit” will help to deal with stubborn stains.

As you can see, nothing complicated!

Corrugated sheet is an excellent roofing covering that can be used to finish the roofs of almost any residential or commercial building. For each individual case, the use of a corrugated sheet of the appropriate type is provided, but the procedure for its installation in most cases remains unchanged.

The corrugated sheet consists of a sheet of steel and a special zinc coating, which protects the material from corrosion. It is best to cover the roof with expensive polymer-coated material. In high-quality sheets, zinc is additionally coated with chromium, after which it is primed and subjected to additional treatment with a polymer paint and varnish material.

For finishing roofs, a universal sheet and a wall variety of material are most often used. When choosing a material, be sure to pay attention to the type and height of the corrugation. In the case of roofs, it is best to use a “wave” with a height of 21-35 cm. A “trapezoidal” corrugation of the same height is also perfect. The optimal sheet thickness is 0.8-1 mm. Additionally, you need to take into account the slope of the slope and the features of the sheathing.

To ensure that the work of constructing a roof from corrugated sheets with your own hands is completed as quickly as possible and with the least amount of labor, it is recommended to prepare in advance everything necessary for the work.

- Screwdriver.

- Special riveting machine. With its help you will process the joints of sheets of material.

- Tool for manual cutting of sheets. It will be discussed in detail below.

- Building level.

- Yardstick.

- Hammer, pencil, nails and other small things used to perform any construction tasks.

It is important to thoroughly prepare for installation work so that everything goes at the highest level and with minimal costs. To begin with, you should properly organize the transportation of roofing material to the workplace. Lift each sheet onto the roof individually.

It is important that there is no gusty or strong wind outside, because... it may cause damage to the material.

The main stage of preparation begins with the organization of insulation, laying moisture and vapor barriers. The latter is attached to the inside of the rafters with an overlap of about 10 cm. The joints are glued with metallized tape.

Check the film before use. Any defects, cracks or other damage are unacceptable. They must be sealed. Remember that properly installed vapor barrier, insulation and moisture protection can save up to 20% of heat and even more.

When using corrugated sheets, it is best to insulate the roof using matte materials. No special recommendations for thermal insulation are given: the slabs are laid in a sheathing, previously covered with a vapor barrier film, and covered with a layer of waterproofing.

Pay special attention to waterproofing. This material will protect the insulation from the harmful effects of moisture, upon contact with which the thermal insulation properties are noticeably reduced. As a result, this leads to the roof being covered with ice, the rooms becoming damp, wooden structures rapidly rotting, etc. Polyethylene film does an excellent job of protecting against moisture. Lay it with an overlap of about 15 cm and secure the joints with adhesive tape.

The corrugated sheet is laid starting from the lower edge of the roof. The material is installed with an overlap. The sheets are fastened using self-tapping screws with rubber seals. They must be fixed in the bends of the corrugated sheet waves.

First of all, it is necessary to make a dense plank flooring under the valley plank. Lay it approximately at the level of the roof sheathing, retreating about 60 cm from the gutter on both sides. Laying the bottom valley boards should be done with an overlap of at least 20 cm. Use nails to secure the bottom strip. Finally, it is fixed together with the roof. If the roof has a gentle slope, experts advise additionally using mastics for compaction.

Place the bottom strip under the roof ridge approximately 25 cm. Place a sealant between the strip and the profiled sheet. It is recommended to fasten the end boards above the sheathing. In the future, this will make it possible to secure the end strips. It is in this order that the wind corner is created.

At the next stage, the cornice strip is mounted and hemmed with a profiled sheet. This bar must be set lower in relation to the profiled sheet. Be sure to take care to create proper ventilation of the space under the roof.

The procedure for laying corrugated sheets is largely determined by the characteristics of a particular type of roof. For example, if we are talking about flat structures, then the sheets are stacked with overlap in 1 wave and the mandatory use of longitudinal sealing gasket. In the case of steep slopes There is no need to install sealant. When finishing hip roofs laying the corrugated sheet begins directly with hip center. The sheets of roofing material are directly aligned with a rope pre-stretched along the eaves.

There are several technologies for laying modern profiled sheets on the roof. For example, in accordance with the vertical installation method, the first sheet is laid at the bottom to create a temporary fastening. The 1st sheet of the 2nd row is mounted using a similar principle. Next, the 2nd sheet of both rows of masonry is fixed so that the result is a block of 3 profiled sheets. Then you need to dock the next one to the laid block and continue to do so until all the allocated space is filled.

Laying can also be done by creating blocks of 3 profiled sheets. To implement this task, you first need to lay 2 sheets of the 1st row, fastening them to each other as securely as possible, and then dock the 3rd profiled sheet of the 2nd row. The laid block is secured after precise alignment in accordance with the cornice. Afterwards, the next block of the same type is created, and the laying continues according to this pattern until the end.

Regardless of the chosen method of installing the corrugated sheet, be sure to check each fixation unit. The reliability, service life and quality of the future roofing covering as a whole largely depend on the connection points.

Rules for installing planks

Installing a roof from the material in question with your own hands requires the mandatory use of different slats. The first of them is the end one. As a rule, it has a two-meter length. If it is necessary to increase the length of the planks, they are overlapped. Mounted along the roof overhang in the direction of the ridge. The fastening is carried out in such a way that at least one wave of the profiled sheet overlaps the end strip. Use self-tapping screws for fixation. They must be fastened in increments of no more than 100 cm.

The next step is arranging the ridge. When performing this stage of work, you need to be as careful as possible, because... the ridge is one of the most important nodes roofing system. Installation is carried out using smooth ridge components, between which professional builders advise laying a layer of additional thermal insulation. In the case of using corrugated profiled sheets, installation of a special ridge seal is allowed.

Work on installing a roof made of corrugated sheets is completed with the installation of abutment strips. These products are two meters long and are laid with an overlap of up to 20 cm. They are fastened with self-tapping screws on the side of the profiled sheets. Self-tapping screws must be installed every 40 cm.

It is important to follow the rules for connecting the roof structure to the wall of the house. Thus, the end of the roof and the walls are connected using a special ridge seal. It is placed between the joint strip and the upper edge of the profiled sheet.

It is important to lay a longitudinal seal at the lateral junctions of the roof. Such an event will help protect the structure from snow and other undesirable elements getting into it. If the roof slope has a steep slope, there is no need to use a sealant.

In the process of constructing a roof from a corrugated sheet with your own hands, there is almost always a need to cut the sheets. This can be done using a variety of tools. The most important thing is that during such processing the protective layer of the sheet is not damaged.

A hacksaw for metal, ordinary scissors for cutting tin, a circular saw, and a professional electric cutter are very suitable for cutting. You should avoid using grinders and other abrasive tools. After cutting with a grinder, the corrugated sheet material will become very fragile and unstable to corrosion, which as a result will not have the best effect on the main characteristics and service life of the roofing system.

After cutting with any suitable tool, the edges of the corrugated sheet must be coated with enamel designed specifically for processing polymer surfaces. Thanks to this, the protection of the corrugated sheet from corrosion will be restored.

You are already familiar with the main aspects of constructing a roof made of corrugated sheets with your own hands. Now you need to understand and learn a number of nuances that will allow you to complete the work at the highest level.

First of all, remember that the corrugated sheet is laid starting from the end of some lower corner. In some situations, you can fasten several sheets at once at the bottom, stepping back from the cornice strip about 40 cm. Fastenings must be made on every 2nd wave.

Special wind corners are designed to protect the end boards. They need to be installed after all the sheets have been laid. Profiled sheets are laid transversely and longitudinally.

In the case of horizontal fastening, the overlap is made such that the top sheet overlaps the bottom sheet by exactly 1 wave. This is relevant for situations where installation is carried out using a special rubber gasket. In the absence of such a gasket, the overlap should be 2 waves. If the profiled sheet is laid vertically, the upper element must overlap the underlying one by at least 20 cm.

The use of the repeatedly mentioned seal can be abandoned only if the roof slope has a slope exceeding 60 degrees. After laying all the corrugated sheets, proceed to forming connections. Longitudinal joints are made along the crest every 50 cm, vertical joints are made along the bottom of each existing wave.

To install the roofing material in question, you can use only self-tapping screws specially designed for this purpose. They are also known as hardware. Approximately 5-8 such fasteners should be used per 1 m2 of roof space. It is recommended to match the hardware to the color of the roofing. On the ridge, fastening is carried out with the obligatory use of a tin gasket. On the main field, you need to use a rubber pad.

Thus, independent construction of a roof from corrugated sheets is quite possible. You just need to follow all the rules and adhere to the basic recommendations, thanks to which even an inexperienced home craftsman can figure out the procedure for attaching profiled sheets and performing all related operations. Follow the instructions received and you will succeed.

Good luck!

Video - Do-it-yourself roof made of corrugated sheets

In individual residential buildings, the installation of roofs from profiled sheets over wooden sheathing must be done in compliance with technology and standards. Construction begins with installation work on the installation of rafters and sheathing. The rafter system is installed in the same way as when working with other structures.

But there are differences when arranging the sheathing. When arranging a roof from profiled flooring, the sheathing is made of wooden blocks with a section of 40x40 mm. Sometimes they are made from edged boards with a width of 100 mm and a thickness of 30. Lathing made from boards has a higher cost. This design will last longer. This fact is decisive for many owners. Many people understand that a stingy customer pays twice. Therefore, they immediately acquire reliable components, although their cost is high.

In this article

Profiled metal sheet

Modern material, affordable, practical. Has many advantages:

- light weight;

- strength;

- ease of calculating the consumption of components;

- high quality characteristics.

The lifespan of materials reaches 45 years. Therefore, the demand for this quality material is not accidental. The length of the sheets is different, reaching 13-14 m. For this reason, on slopes with a short length, the material is placed without overlaps or horizontal joints.

Types of lathing

The roof sheathing made of this material is made solid or with a thinned appearance. The device is located in the area of the structure’s overhangs. Or in the location of different junctions. And a continuous structure is made in the area where the ridge of the structure is located. This type of roof sheathing is considered correct.

As usual, when working with wood, all parts are treated with fire retardants and antiseptics. All costs of component materials must be indicated in the estimate for the work. These are protective agents against fire, rotting and against the appearance of microorganisms.

If the coating is completely sealed, this does not mean that moisture from the outside air will not destroy the elements over time. Its presence can cause wood to rot. Before installation, wooden blocks are nailed along the legs of the rafters.

Counter-lattice

It is designed to secure waterproofing and create gaps for ventilation under the coating. During operation, condensation appears on the surface of the material from the inside. This occurs when there are temperature changes in the air outside.

Waterproofing is fixed at the places where it passes. When condensed inclusions fall on the surface of the structure, the drops flow into gutters intended for drainage. Therefore, the waterproofing installed here plays an important role. It provides a metric focused on structural preservation.

The board is fixed to the body of the counter-lattice at predetermined distances, which are called steps. Its length depends on the angle of inclination of the structure and the type of profiled flooring purchased for the structure. There are special tables that can be used to determine: the pitch of elements intended for certain types of material.

They depend on the design of the rafters and the slope. This is how the installation of pitched roofs or completely different ones is carried out. If the size of the slope is greater than the length of the profiled sheet, then the material must be ordered in such a way that the fastening points in the transverse joints on the sheets fall on the boards in the sheathing.

Important: the overlap that is created between the rows of coating should be located in mm from 100 to 200. The slope of the structure should not be overlooked.

Adjacent sheets of material are laid with an overlap in only one wave. If all of the above types of work were performed correctly. Without any violations, the created structure will provide excellent tightness in operation. This will happen even in the off-season.

As soon as the installation work on arranging the sheathing, as well as waterproofing, has been completed, work on installing corrugated sheeting should begin. It starts from one of the corners on the slope located below.

If there is a capillary groove on the sheet of material, then it is advisable to carry out the work from the left edge of the structure. Then the edge of the subsequent element will cover the capillary groove located on the previous sheet.

Sometimes the design is somewhat more complex than an ordinary gable or single-pitch roof. And it is made up of planes that intersect. Yes, there are several more. Before starting installation, you need to sketch out a detailed diagram on a sheet of paper. On it indicate the location of the sheets throughout the entire coating. It’s easier to work this way and there’s no confusion!

The first sheet of material is laid so that it protrudes slightly beyond the location of the pediment. Experts believe that this distance in mm should be 300. The overhang of the cornice at the side structure of the building should be between 300 and 400 mm.

Fixing the material

After placing the first sheet, secure it with a self-tapping screw. Then, with a longitudinal overlap, the subsequent sheet is installed and then temporarily secured. After placing three or four elements, the row is well trimmed, focusing on the cornice. Then all elements are fixed to the structure.

When securing adjacent sheets, rivets or shortened screws are used. If the slope of the entire roof is between 12 and 14 mm or even less, then both transverse overlaps and their longitudinal counterparts are well sealed using roofing sealants.

If all the work is done as indicated, the roof will be airtight. Due to the fact that the covering sheets are attached to the sheathing structure through the lower wave, it is considered responsible for the material.

Important: to strengthen sheets of profiled flooring, only self-tapping screws with press washers and gaskets made with neoprene rubber should be used. They are special! Self-activity in this work will only do harm.

Neoprene rubber and ordinary rubber differ both in properties and characteristics. When performing work, neoprene rubber tends to vulcanize. But it does not lose its original appearance and remains elastic. This is a property that ordinary rubber cannot provide. Therefore, there are no water leaks, and there cannot be any.

Self-tapping screws for roofing have a drill-type tip. For this reason, they themselves can make holes in the body of the profiled sheet. But here you have to be careful. If the sheet of material has a thickness of more than 0.5, it is better to drill holes for fastening. The diameter of the holes should be slightly larger than that of the screws. This compensates for linear expansion of roof elements during possible temperature changes.

To work with self-tapping screws, screwdrivers and electric drills are used, the speed of which is adjustable. Properly used self-tapping screws press the gaskets very tightly to the sheet of material. The pressure washer must be free of defects after fastening!