Of course, a modern house with a stove is an anachronism. A thrifty owner installs a comprehensive, economical heating system.

However, what could be better than sitting in front of the fireplace on a cold evening or taking a steam bath in a Russian bath? But a fireplace and a good stove in a Russian bath cannot do without stove pipes and chimneys. This equipment will also be relevant in the construction of stationary grills and barbecues. The design of chimneys and chimneys is quite simple, but has some nuances.

Stove pipes and chimneys can be divided into several large groups depending on the material they are made of. So they can be made using brickwork, from metal pipes of various types, as well as from multilayer materials.

In addition, stove chimneys may differ in the way they are installed:

- Wall chimneys are mounted directly into the thickness of the walls of the building, external or internal. In this case, stoves and fireplaces can also be installed directly in the walls of buildings.

- Suspended chimneys are mounted on the external walls of buildings.

- There are also main chimneys. Such structures are mounted separately, next to the stove.

SNiP requirements for stove pipes and chimneys

Existing SNiPs impose certain requirements on chimneys and chimneys under construction:

- They must effectively remove combustion products.

- They must have sufficient height above the roof ridge.

- Their internal cross-section must be sufficient to completely remove smoke.

- Pipes must be resistant to high temperatures.

- They must be durable, the upper part of the chimney must withstand gusts of wind

Let's start with the height of the chimney pipe. A sufficient chimney height ensures good draft and effectively removes combustion products, preventing the room from becoming smoky and maintaining draft. However, excessive pipe height can lead to condensation and reduced draft.

The diameter of the chimney or its internal cross-section is calculated based on the size of the firebox. It increases with the volume of the combustion space, in proportion to it. An insufficient cross-section of the chimney leads to smoke, but an excessive diameter will, on the contrary, lead to a decrease in draft.

What should the chimney be made of, what materials are prohibited from being used?

The main requirement for the material for the manufacture of chimney stove pipes is heat resistance. The minimum fire safety threshold for chimney pipe material is set at 30 minutes and 1000 degrees. In constant operation, the pipe material must withstand temperatures of 500 degrees without damage, since the temperature of combustion products rarely drops below 300 degrees.

The reserve of 200 degrees is due to the fact that soot accumulating in pipes has a tendency to spontaneous combustion.

Strict requirements are also imposed on thermal conductivity. The temperature of the outer layer of chimney pipes should not exceed 90 degrees, and in places where they interface with flammable structures - no higher than 65 degrees.

We especially note that combustion materials have an aggressive chemical composition and the material from which the stove chimney pipes are made must effectively withstand the adverse chemical environment. In addition, the part of the pipe extending outside the premises is exposed to climatic conditions and must not be destroyed due to temperature changes.

The traditional material for making chimneys is refractory brick. It almost perfectly meets all the requirements for chimney pipe materials. However, the construction of brick chimneys and chimneys requires certain skills.

In addition, the brick must be individually selected for each heating device. So in stoves, the temperature of combustion products is usually kept at 250 degrees, but in fireplaces, when exposed to direct fire, it can reach 400 degrees. Thus, it is recommended to make the walls of a brick chimney for a fireplace from fireclay bricks, laying a wall thickness of more than 15 centimeters with seams of 5 mm. This significantly increases the cost of manufacturing chimney pipes for fireplaces, as well as the requirements for the strength characteristics of the foundations under the fireplace.

Chimneys and chimneys made of asbestos cement

Asbestos-cement pipes are a relatively cheap but also reliable material for the manufacture of chimney pipes. They can be used for the construction of chimneys in stationary barbecues, light buildings, and baths. When installing such pipes, special attention should be paid to areas where they interface with flammable materials, since an asbestos-cement pipe may crack during service.

Stainless steel chimneys

As a rule, stove chimneys made of stainless metal can be used in the construction of heating systems with gas boilers. Such a pipe becomes very hot from the passage of combustion products and therefore it must be reliably equipped. In addition, it is necessary to pay special attention to the quality of the pipe from which the chimney is made. Thin stainless metal, especially in low-quality pipes, can develop cracks, which can easily cause a fire.

Also, a disadvantage of this pipe model is the strong formation of condensate on their surface.

Pipes and chimneys made of multilayer composite materials

New models of pipes, also called “sandwich pipes,” appeared on the market relatively recently, but have already proven themselves well. Multilayer pipes are manufactured in industrial conditions, usually in the form of meter-long sections; during installation, the chimneys simply need to be connected. Such a pipe is reliable in terms of strength and is highly resistant to high temperatures and aggressive chemical environments.

Typically, a sandwich pipe has three layers. The inner surface is made of stainless steel, the upper surface is made of galvanized steel. Insulating material is placed between them.

Such a pipe is light in weight and quite undemanding for installation. It does not put a lot of stress on the oven. As a disadvantage, we can note the high cost of such structures and a relatively short service life. However, the time of trouble-free operation of a sandwich pipe depends on the specific manufacturer. During operation, such a pipe is subject to thermal deformation, which can compromise its integrity.

Multilayer pipes may have a different composition. So the inner part can be made of refractory clay, and basalt wool can be placed between it and the upper shell of lightweight concrete. This configuration of multilayer pipes significantly increases their service life. In addition, various decorative coatings can be glued to the outer part of such a pipe.

Modular chimneys

Modern industry offers ready-made construction kits for self-installation of chimney stove pipes. All components are manufactured at industrial plants and then easily assembled at the installation site.

How to arrange a chimney passage through the roof?

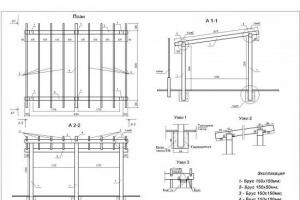

1 - chimney chimney, 2 - rafter leg, 3 - fireproof thermal insulation material, 4 - load-bearing beam

Typically, the installation of chimney pipes is carried out during the construction of a building or structure, simultaneously with the installation of a furnace or heating system.

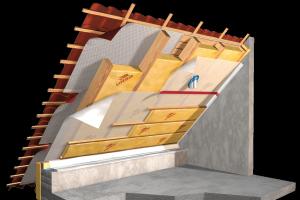

With this approach, you can easily adjust the relative position of the rafters to the chimney and create the necessary gaps between the wooden materials and the chimney. They must leave at least 15 centimeters and are laid with fireproof material, such as basalt wool.

When building a stove or fireplace, when calculating its foundation, it is necessary to take into account the weight of the chimney pipe.

The upper part of the pipe can be equipped with a protective device that prevents sparks from flying away on one side, and rain from entering the pipe on the other.

Laying a brick chimney - training video

This article will help you decide on the choice of a metal chimney for your stove. Choose the best option for specific conditions and budget.

Collapse

Material selection

The material plays a huge role; the service life of the chimney, its ability to withstand various aggressive chemical compounds, reliability and strength depend on it. A steel chimney for a stove is made from three main materials: stainless steel, galvanized and ferrous metal. Now let's look at each material in detail.

Stainless steel

Made from heat-resistant and acid-resistant stainless steel. A good chimney should have a thickness of 0.8 - 1 mm; a thinner one will not last so long.

Characteristics:

- Able to withstand temperatures of more than 600 degrees, and have a long service life.

- They are not afraid of many substances, and work calmly with constant contact with nitric acid, sulfuric acid, creosote and other substances that are part of the combustion products of coal and firewood.

- They can be either single-walled or double-walled, with thermal insulation between the pipes. Such a chimney is safe and can be installed in any buildings: residential buildings, baths, saunas, technical buildings, etc.

Cink Steel

It is a budget option for construction. The thickness of the pipes ranges from 0.3 to 01 mm. It is made of steel coated with a layer of zinc, thanks to zinc it has good characteristics of resistance to alkalis and acid combustion products.

They are installed in the same way as stainless steel pipes. They are used less frequently as a material for stove chimneys, as they have a shorter service life and are less reliable in terms of their design and metal thickness. To extend the service life of galvanized pipes, they need to be insulated, this will reduce the formation of destructive condensate.

Black steel chimney

They are now very rarely made from black steel, due to the fact that they have a short service life. Such a chimney is justified only when the budget is very limited. They are made from boiler or ordinary steel, the thickness of the pipes ranges from 0.6 to 2 mm.

More often they are installed on small sauna stoves or in country houses, the use of which will be periodic. Can be used for stoves in greenhouses and outbuildings. With severe overheating, a lot of scale forms inside the pipe, which blocks the flow of the pipe.

Types by design

The iron chimney for the stove can be divided into two types according to its design: single-walled and double-walled. Now let's take a closer look at each of them:

Single wall

Based on the name, they have only one wall. These are installed mainly in the finished chimney duct of the stove, and serve as a sleeve. Also used in outbuildings, garages, etc. such a chimney. They can be made from stainless steel, galvanized steel, or regular iron.

They are more fire hazardous, and therefore are used in those areas of the chimney where the risk of fire is reduced. The cost of such pipes is two times lower than double-walled ones.)