When designing a new building, quite often you have to decide on the choice between ondulin and corrugated sheeting as a roofing covering. In order to make the most optimal decision about whether ondulin or corrugated sheet is better, you will need knowledge of the basic characteristics of both materials.

Ondulin

To make ondulin (or flexible slate), ordinary cellulose cardboard is used, where bitumen and heat-resistant resins act as impregnation. Giving the desired color is achieved using mineral dyes.

As for the name of the material, this was the name of the French company that was the first to produce flexible slate 50 years ago. If we talk about our country, then acquaintance with ondulin occurred approximately in the 90s of the 20th century.

Profiled sheet

The coating is made on the basis of corrugated steel sheet. Its waves have a height of 20-80 mm, which allows the material to be given a high level of transverse rigidity. To protect the metal surface from moisture, a single-layer or multi-layer anti-corrosion coating is used.

It can be made from:

- Zinc. Galvanized profiled sheets are most often used to create temporary fences and roofs in warehouse and industrial buildings. The unpopularity of the material in private housing construction is explained by the fact that it is produced in only one color.

- Polymer. To improve performance characteristics, galvanized profiled sheets in this case are additionally coated with a polymer layer. This increases their mechanical strength, ability to resist corrosion and decorative effectiveness.

Comparison of two materials - pros and cons

Cost - which is cheaper

The first task that one has to face when choosing between two roofing options is to determine what is cheaper - ondulin or corrugated sheeting. As of March 2017, a comparison of prices leads to the fact that ondulin is approximately 30% cheaper.

It remains to be seen whether the higher price of profiled sheets is justified by their performance characteristics.

Service life of corrugated sheets and ondulin

Next, it is important to determine which coating lasts longer, ondulin or corrugated sheet. Manufacturers of flexible slate usually provide a guarantee for their product of 40 years or more. As for the profiled sheet, the service life is indicated somewhat longer - 50 years. In any case, both coatings can provide the roof with fairly durable operation.

However, you should know some nuances:

- Some varieties of ondulin can effectively withstand moisture for only 15 years, and only if the installation technology is followed.

- Some time after installation, ondulin fades under the influence of sunlight, but this does not reduce the service life of ondulin.

- The actual durability of the profiled sheet is largely influenced by the thickness of the protective zinc layer. In an effort to win a competitive race, this is where many corrugated sheeting manufacturers often try to save money.

- When cutting corrugated sheets with an abrasive tool, you should keep in mind that in this case its corrosion protection is violated. This can cause rust along the cut line.

Therefore, it is not possible to determine which is better for the roof - ondulin or corrugated sheeting, by comparing their service life. There is approximate equality here, since this indicator is influenced by many additional factors.

Strength characteristics - which is better for the roof

It is very important how the roof will be affected by snow load or high wind. If there are other outbuildings or trees on the site, then there is always a risk of a piece of neighbor’s siding or a tree branch flying onto the roof.

The popular brand of flexible slate “Smart” has the following characteristics:

- The maximum permissible snow load is up to 960 kg/m2.

- The maximum permissible wind speed is 175 km/h.

The accompanying documentation for profiled sheets does not provide such information.

- Winds with a speed of more than 117 km/h are called hurricane winds. It is capable of causing large-scale destruction, damaging houses and uprooting trees.

- The snow load on roofs in our country usually does not exceed 600 kg/m2. Ondulin roofs are always pitched, and the seams are usually not waterproofed.

At first glance, flexible slate wins here.

But one should refrain from hasty conclusions:

- Steel sheets are an order of magnitude stronger than bitumen-impregnated cardboard. For example, ondulin fences can only keep out small pets. As for fences made of profiled sheets, such structures do an excellent job of their duties, having good anti-vandal characteristics.

- The ability to withstand snow and gusts of wind indicated for flexible slate is also characteristic of profiled sheeting. The main thing is that in both cases a continuous sheathing is used.

- During severe frosts, ondulin becomes fragile. And if some heavy object falls on such a roof, it can cause irreparable damage. In the case of corrugated sheeting, everything is usually limited to a small dent. The pros and cons of a corrugated roof make it a winner in terms of strength.

Transportation

Next, you need to compare ondulin and corrugated sheeting according to the features of its transportation from the place of storage or purchase to the construction site. This criterion is directly dependent on the size of the sheets and their weight: the lower the weight, the more convenient the transportation.

Here metal products are inferior to ondulin:

- The weight of flexible slate measuring 195x95 cm is 6 kg.

- Corrugated sheeting has a standard width of 120 cm, but the length can be up to 6 m. The weight of a linear meter of the lightest type of material with a thickness of 0.4 mm is about 4 kg.

Installation

As for installation work, the advantage is given to the material whose sheets are large in size. This makes it possible to reduce the number of joints while increasing the speed of work. The significant length of the profiled sheets allows in many cases to completely cover the roof slopes without using longitudinal overlaps.

Metal products have a couple more advantages:

- Cheap sheathing. To cover the roof with profiled sheets, sheathing is installed in increments of 30 cm. With an increase in the thickness of the metal and the height of the profile wave, the permissible pitch of the sheathing also increases. The frame for the ondulin must be solid, with virtually no gaps: this implies high costs for its sheathing. This criterion can be attributed to the comparison mentioned above, which is cheaper - ondulin or corrugated sheet.

- Self-tapping screws can be installed at the bottom of the wave: due to the use of rubber press washers, the connections are airtight. To fasten ondulin, it is allowed to use only roofing nails, and the place where they are driven can only be at the top of the wave. This type of fastening is not as durable.

Noise level

Results

Each person, having compared ondulin and corrugated sheeting, will be able to come to certain conclusions. If the strength of the roof covering is considered a priority, then profiled sheets have an advantage. At the same time, ondulin has its advantages, the main ones being the lightness of the material and the ease of its installation.

Choosing a roof is one of the most important stages when building a house.

And since building material manufacturers now offer us a huge amount of roofing materials, developers have to decide what material to use for roofing.

After all, all materials are different.

They differ in appearance, characteristics, installation principles and cost.

Here, as they say, who likes what.

However, in most cases, the developer chooses between ondulin and corrugated sheeting.

The characteristics of both materials deserve respect.

And their cost is approximately the same.

However, there are differences that can affect the choice of roofing material.

Characteristics of ondulin

Ondulin (Euro slate) is a building material that is intended for cladding and roofing work.

To produce this material, the method of pressing cardboard under high pressure is used, which is enriched with bitumen.

After pressing, the cardboard is coated with resin and paint.

Therefore, ondulin is not only a very durable material.

He is also very handsome in appearance.

The material is produced in standard sheets with overall dimensions of 940 x 2000 mm. Sheet thickness 2.7 mm.

The weight of an ondulin unit is 6 kg.

Ondulin, due to its characteristics, has become very popular in our country.

The plasticity and single-layer nature of this material make ondulin very resistant to various mechanical damage.

And the special resins that are used in the production of ondulin provide reliable protection for the roof against leaks.

After the fastening nail pierces the ondulin sheet, a microscopic drop of bitumen is released at this point, which seals the gap between the material and the nail.

Ondulin is not subject to corrosion because it contains no metal elements.

It does not rot because it is impregnated with resin.

Ondulin is an environmentally friendly product.

The small thickness of the material makes it possible to cut it with a simple hacksaw in order to use it to cover any, even the most complex roofing elements.

Despite its small size, Euro slate can easily withstand snow cover 50 cm thick.

Advantages and disadvantages of ondulin

Yes, this wonderful material has many advantages.

But, unfortunately, it also has disadvantages.

But first, let's look at the advantages:

- excellent sound insulation. Ondulin does not allow noise to pass through. Therefore, when it rains, it absorbs the noise of falling drops, falling hail, and water that flows down the roof. Euroslate is the quietest roofing material;

- good resistance to weather conditions. Anyone. In the sun, ondulin practically does not heat up, unlike steel metal tiles or corrugated sheets;

- ease of installation. Ondulin is a very plastic, flexible material. It is very easy to cut. It is very easy to install on the old coating;

- environmental cleanliness. Ondulin does not contain asbestos, which is very harmful to the human body. Rainwater that flows down the roof can be used, for example, for irrigation without additional treatment;

- resistance to corrosion, rot, and the effects of fungi, microorganisms and bacteria;

- durability. 50 years;

- affordable price. Today many people can afford ondulin for the roof.

In addition to many advantages, ondulin also has disadvantages.

And you should know about them:

- low fire safety. Since ondulin is paper and bitumen (resin), the risk of a fire on the roof, for example, due to a lightning strike, is very high;

- the choice of colors is small;

- the material is not resistant to ultraviolet radiation. That is, under the sun's rays it simply fades very quickly;

- under some conditions, ondulin is not resistant to mechanical damage. It is not recommended to walk on it after rain. If the material is wet, then after walking, dents from your feet may remain on it;

- Since the material is manufactured in the form of sheets, a large number of joints are formed during installation. And if some inaccuracies were made during installation, leaks may occur.

It's time to deal with the corrugated sheets. Also a very interesting building material.

Advantages and disadvantages of corrugated sheets

Corrugated sheet is a profiled steel sheet that has good lateral rigidity.

For the manufacture of corrugated sheets, the cold stamping method is used.

The depth of the profile depends on the size of the stiffeners and the thickness of the metal.

The thicker the steel sheet, the deeper the stamping and the greater the strength of the product.

The corrugated sheet can have a thickness of 0.5 - 1.2 mm.

To protect the sheet from corrosion, it is coated with a polymer or a layer of zinc.

Or both at the same time.

Today, galvanized corrugated sheeting with a polymer decorative coating is in great demand.

Since steel in rolls is used to produce corrugated sheets, its length can be any.

And the width of the sheet has limitations: 980 - 1850 mm.

Advantages of corrugated sheets:- high fire safety. After all, the base of the corrugated sheet is a metal sheet;

- high resistance to natural and mechanical influences. The material does not lose its original appearance for almost its entire service life;

- large selection of colors and shapes;

- easy installation. The weight of the corrugated sheet is small, and it is not difficult to secure it to the roof. Even an amateur can handle this if he has some skill;

- during installation, the number of joints is minimal, which significantly reduces the likelihood of leakage;

- despite the fact that corrugated sheeting is a metal product, the plastic coating reliably protects the base of the sheet from corrosion;

- environmental friendliness;

- durability. also 50 years old;

- affordable price.

Well, about the shortcomings, of course:

- The sound insulation of the corrugated board is very poor. And when it’s raining or hailing outside, all the impacts on the roof are very audible. But this drawback is mitigated by a sound protection device under the corrugated sheeting;

- Condensation often forms under the sheets. But this problem can also be easily solved: arrange a ventilated space under the corrugated sheeting;

- difficulty of use on complex roof structures. The size of a standard sheet of corrugated board is large, and it has to be cut. And this is not easy. The sheets are laid on the roof with an overlap. Which reduces the actual width of the sheet by 50 cm.

Which is cheaper: ondulin or corrugated sheeting

One of the most important issues when choosing a roofing material is cost.

You should know that in addition to the material itself, you also need to purchase components.

Despite the fact that more components are required for corrugated sheeting, the cost of components for ondulin is higher.

As a result, ondulin turns out to be 5% more expensive for the same roof area than corrugated sheeting.

Well, for example, at a company that produces corrugated sheets, it is loaded onto pallets.

But they have loading equipment.

And you will have to hire a loader for an additional fee, or unload the material one sheet at a time.

Believe me, this is very difficult.

A heavy vehicle will be required for delivery.

With ondulin everything is much simpler.

Since its dimensions are smaller than corrugated sheets.

If desired, it can be transported by car.

Or by small minibus.

Now about the installation.

Since ondulin is laid on a solid corrugated sheet, its installation can be easily done by one person.

The installation technology is very simple, and the home owner will do everything quickly and efficiently.

With corrugated sheets everything is more complicated.

Even the manufacturers of this material indicate that at least 2 people should work with corrugated sheeting.

Both during unloading and during installation.

And how can one lay a sheet that is 2 meters long?

It's a sail!

At best, he will fly away and injure someone below.

In the worst case, it will fly away along with the installer.

That is, you will have to hire a team of professional roofers.

And these are additional costs.

Which is better: ondulin or corrugated sheeting

As you can see, both ondulin and corrugated sheets have many advantages and disadvantages.

The fire safety of corrugated sheets is high.

It is a little cheaper, and will certainly pay off if the roof area is large.

Since the length of corrugated sheets can reach 6 meters, the number of joints will be minimal.

This means that the likelihood of leaks is minimized.

But the sound insulation of the corrugated sheets is zero.

Ondulin has excellent sound insulation.

However, its fire safety is very low.

Installation of ondulin should be done very carefully.

Because there will be a large number of joints, and if the sheet is placed unevenly somewhere, a leak may occur.

In terms of price, corrugated sheeting and ondulin practically do not differ from each other.

The service life of the material is approximately the same.

In principle, there should be no problems during installation.

The technology is very simple.

However, if the roof has a complex structure with a large number of bends and valleys, then laying ondulin is easier.

It is flexible and cuts well.

Corrugated sheeting is no different in flexibility.

And there is a big difference in the sheathing: under the ondulin it should be continuous, but under the corrugated sheeting you can lay boards with some spacing.

Saving on material!

Despite the fact that corrugated sheeting has many advantages, it is still better to use it for cladding and making fences.

But it would be better to lay ondulin on the roof of the house.

In any case, everything is decided by the developer.

The roof covering must withstand bad weather, protect from heat in summer and cold in winter. At the same time, I want it to be inexpensive, but durable and reliable material. Based on these parameters, future owners of suburban real estate often have a question: what to choose: corrugated sheeting or ondulin.

Externally, both materials are very similar. They have a ribbed surface and look neat. But external similarity is perhaps the only thing that unites them. In fact, corrugated sheeting is a metal profiled sheet, and ondulin is bitumen. Therefore, to make a choice, we will consider the characteristics of each material separately.

Ondulin (Euroslate)

The main components of Euro slate are cellulose and bitumen. Additionally, this material contains mineral fillers. That is, in essence, ondulin is sheets of durable cardboard impregnated with bitumen. One such sheet weighs no more than 7 kg. The material is soft and rough. It is easy to cut, drill and nail, which undoubtedly speeds up the process of laying Euro slate.

It also has other advantages. For example,:

- Long service life, which is at least 25 years.

- The material does not weigh down the roof, unlike classic slate or metal.

- Suitable for roofs with complex shapes.

- Withstands snow up to 50 cm deep.

- Absorbs sounds from the street.

- Does not rust or oxidize.

- Environmentally friendly material.

But, there are also several disadvantages. For example, ondulin:

- It is a fairly flammable material. Bitumen ignites very quickly and is capable of maintaining the combustion process for a long time.

- Although it comes in several colors, it will still fade after a while.

- It has a rough surface that cannot be washed properly. And dust and dirt linger on ondulin very well.

- If it is located on the north side of the roof, it will easily begin to become covered with moss. You will have to clean it periodically.

- It can soften in the sun, but in winter it is too fragile. Therefore, installation is only possible under certain weather conditions.

- It is usually laid on lathing, which complicates the work process and increases the cost of the entire roof.

In addition, ondulin is very often counterfeited. Cheaper analogues do not last even half the standard service life.

Corrugated sheet

Metal profiled sheets are made on the basis of cold-rolled, hot-dip galvanized steel. As a rule, a layer of zinc (about 30 microns) is applied to a sheet with a thickness of 0.14-1.5 mm. This is what makes corrugated sheeting such a cheap, but at the same time durable material. In addition to the zinc coating, such sheets are coated with a layer of anti-corrosion coating and a primer. A protective varnish is also applied to the inside, and a polymer coating is applied to the outside.

Corrugated sheeting may differ in profile, thickness, and corrugation height (it can range from 8 to 150 mm). The width of the sheet is usually standard (about a meter), but the length of the sheet is cut to order or by the buyer himself at the construction site. 1 “square” of corrugated sheeting weighs 5-8 kg, which is also not very much.

Other advantages of this material include:

- Long service life (up to 50 years).

- Fire resistance. Therefore, corrugated sheeting can be safely used for a home with a stove type of heating, as well as for a bathhouse.

- Does not require lathing. Corrugated sheeting can be laid on boards in increments of 0.3 meters.

- Does not change its characteristics in conditions of extreme heat or cold, so installation can be performed in any weather.

- Thanks to the smooth surface, dirt, dust and snow do not accumulate on the corrugated sheet.

- The coating does not change its color when exposed to sunlight.

- Environmental friendliness.

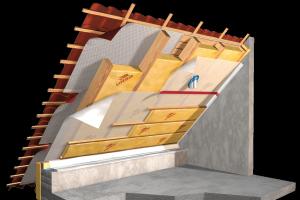

There are also disadvantages. For example, profiled sheets do not suppress noise well. Therefore, on the top floor you will clearly hear hail, rain and crows walking on the roof. Also, the use of corrugated sheeting for buildings with an attic floor requires additional insulation of the roof. Otherwise, there is a risk that condensation will begin to accumulate.

If the sheet is severely damaged, corrosion may form on it.

Cardboard and metal, what to think about?

Most likely, having learned what ondulin is made from, many may think so. But it's not that simple. The fact that it is cardboard does not mean that the material will delaminate after the first rain.

In fact, cellulose, and also in collaboration with bitumen, turns into one of the most durable natural materials. For example, ancient wooden houses have been standing for several centuries. This strength is achieved through very flexible and durable cellulose fibers. Therefore, you should not immediately write off ondulin. Instead, it's worth considering how each material performs in different situations.

Loads

If you believe the manufacturers of high-quality ondulin, this material can cope with a load of 960 kg per 1 m2. But nothing concrete can be said about corrugated sheets. The producers themselves are silent. The thing is that there are many brands and varieties of profiled sheets. The greater the height of the corrugation (wave), the greater the strength and resistance to deflection the material will have.

It is on this basis that corrugated sheeting is divided into several categories. If we are talking about arranging a roof, then you need to choose only roofing and load-bearing materials.

Ondulin is sold only in one format, so it is more difficult to make a mistake. But some people even use load-bearing type corrugated sheets as interfloor floors. Therefore, even if we don’t know exactly how much it can withstand, it is clearly not inferior to Euro slate.

Resistant to damage and weathering

In this matter, ondulin clearly loses. For example, in the fall it can even be hollowed out by woodpeckers who like to catch midges on the roof. Moreover, there are reviews in which people say that birds literally pierce right through the material.

And you can’t stay in the heat with Euro slate. If it’s +40 degrees outside and you need to adjust the antenna, then it’s better not to go on the roof. Ondulin softens greatly, so it can bend greatly under the weight of a person.

Also, many live in regions with strong, almost storm-like winds. Technically, both ondulin and corrugated sheeting differ in the so-called windage. But for some reason, it is metal profiled sheets that are torn off the roof more often. This is due to the fastener. The fact is that the Euro slate comes with special nails, which are equipped with a wide head and are distinguished by a special carving. These elements are hammered into the sheathing, so the ondulin sheets sit firmly. Corrugated sheeting is usually attached to ordinary self-tapping screws, which you have to purchase yourself.

If we talk about atmospheric influences, then there will be problems with corrugated sheeting in winter. It is necessary to install special snow guards on it, since its surface is quite slippery. Ondulin has a rough structure, so snow is better retained on it.

Heat preservation

This is one of the fundamental differences between the materials. Although bitumen sheets can become soft under the influence of positive temperatures, this material has low thermal conductivity, so the space under the roof will not heat up. This means that in the attic or attic, even at +40, it will be quite cool and not cold in winter.

In this case, metal is inferior. The corrugated sheet instantly heats up under the sun. Let it not change its characteristics; you should not walk on such a roof in slippers. The attic will also be quite hot. In winter, metal, on the contrary, turns into a piece of ice. But this problem can be solved with the help of insulation, which is placed under the corrugated sheets. True, this will increase the cost of the entire roof.

Condensation Formation

Metal actually collects moisture from the air very well, and since it is cold in winter and hot in summer, this leads to condensation. Some complain that drops of water even roll down the walls. But, this problem is solved again by laying insulation (it is necessary to create a gap for ventilation and provide air flow). Then the moisture will leave.

You can also combat condensation by performing a more complex roof installation. To do this, you will need to organize a lathing on which a layer of waterproofing or a special roofing membrane is laid. Then a small gap is made and the corrugated sheet itself is fixed to the counter-lattice. In this case, moisture will accumulate on the inside of the roofing and flow down the waterproofing.

In fairness, it is worth noting that such a problem existed with the old corrugated sheeting. Today, sheets of roofing material are produced, which are coated on the inside with a special anti-condensation compound. This is not due to the fact that manufacturers suddenly began to care about customers, but because this makes sheet material more convenient to store in a warehouse. This coating itself, upon closer examination, resembles pile. Drops of moisture are retained on it, and when the temperature stabilizes, the fibers simply dry naturally. This option is more expensive, but significantly simplifies roof installation.

Other differences between ondulin and corrugated sheets

Yes, most people prefer metal over “cardboard,” but to complete the picture, it’s worth considering a few more points:

- Although ondulin fades, many note that if you buy a glossy coating, after a few years it will become matte and a tone lighter. But the burnout occurs evenly, so it’s not very noticeable.

- Since bitumen material is more flexible, elastic and lightweight, it can be transported in the trunk of your car and at the same time on the roof. Corrugated sheeting is hard, so it can only be transported on the roof of a car. Due to the greater weight, you will be able to bring half as much in one trip.

- If you scratch the corrugated sheet too much, after some time corrosion will begin to appear in this place. Ondulin is not subject to such shortcomings.

- But in installation, corrugated sheeting can be called the best option. The fact is that ondulin is only suitable for roofs whose slope is at least 14 degrees. Metal sheets can be placed however you like.

Thus, although two completely different materials, they are considered optimal for roof construction. But which one is better, you should choose based on your specific requirements and climatic conditions.

The modern market for roofing materials allows you to choose a coating to suit every taste and budget. And there are two very popular ones in it, seemingly similar, but completely different in essence materials - profiled metal and bitumen sheets.

They cost approximately the same, look similar from a distance, have a recognizable geometry, and therefore often confuse future home owners: where to choose? Especially considering the conflicting customer reviews.

In this case, let's take a closer look at those situations where it is more preferable ondulin or corrugated sheeting: which is better for the roof of a residential and cold attic of a house, northern or southern region, and also what exactly pleases and upsets in both types of roofing.

Corrugated sheeting and ondulin are really similar in appearance, because both are long sheets bent on a machine into a certain profile. But in terms of raw materials, both materials differ radically:

The basis for the production of ondulin is the most common waste paper, which is processed at the plant. Cardboard in the finished sheet is from 400 to 500 grams per square meter. As a result, such a mass looks like a porous material and represents fibers from recycled synthetic, textile and wood raw materials.

And not everything is as simple as many people think. There are certain quality requirements for such raw materials: there should be no lumps, cracks or tears in the cardboard. Only smooth ends and a uniform layer, which can in the future ensure uniform and high-quality impregnation with molten bitumen. In addition, the cardboard must have some tensile strength and a moisture content of no more than 6%.

But corrugated sheets today are produced on the basis of cold-rolled but hot-dip galvanized steel. In production, zinc is applied to a steel sheet with a thickness of 0.14 to 1.5 mm in a layer of about 30 micrometers. Galvanizing itself reduces the cost of the material, but provides a good level of corrosion protection. The finished sheet has fairly high mechanical strength and bending rigidity.

Of course, the very comparison of cardboard and steel sounds funny. How can you even talk about something like this seriously? This is exactly what many people think and are mistaken. Indeed, in fact, cellulose is rightfully considered one of the most durable materials in existence. Look at the old wooden houses that have been standing for the second century, and they are not afraid of either wind or rain.

It's all about these flexible and durable fibers created by nature itself - cellulose. And strong wood in practice can withstand a much greater load than thin metal, like a tin can. Because it’s all about the technical characteristics of the finished product.

By the way, e There is such a subtype of corrugated sheeting as metal slate - this is also a thin profiled metal sheet, which differs only in its wavy shape. It looks more harmonious on the roof than the angular traditional metal profile, but there are still many questions about its high-quality fastening and protection against leaks. In appearance, such a roof can no longer be distinguished from ondulin from afar.

Load calculation: when strength is a priority

According to modern European slate manufacturers, their roofing covering can withstand loads of up to 960 kg per square meter. But in the case of corrugated sheeting, you will not find a clear answer anywhere, because everything depends on its brand and intended purpose.

The whole secret is that The height of its corrugation, unlike metal tiles, can be very different - from 8 mm to 150 mm. And the higher the wave, the stronger the material, and the more resistant it is to deflection.

And it is precisely based on these stiffening ribs that the metal profiled sheet is divided into separate categories:

Only roofing and load-bearing corrugated sheeting are suitable for roof construction. Moreover, for example, if you want to play it safe, you won’t be able to do anything with ondulin – it always comes in the same format.

But corrugated sheets can be purchased with the corrugation height chosen at your discretion, and provide the roof with almost any strength. After all, its load-bearing appearance is even used as a basis for covering an entire floor!

Therefore, if you are faced with the question of whether the roof of your house or the same veranda will withstand a heavy snowy winter, when your region is famous for just such a climate, then it is better to give preference to corrugated sheeting.

All elements: resistance to mechanical damage

There is also an interesting observation about ondulin: in some regions of Russia it can be damaged by woodpeckers who catch flies in the fall. There are reviews that these small-packed birds literally break through this coating. Although ondulin itself can restore its shape, such damage does not bode well.

You've also probably heard that Euro slate bends underfoot. This is partially true, and this only happens in unbearable heat of more than 40 degrees. In this case, under direct sunlight, it can soften so much that it will actually sag from a person’s foot and will not even recover.

Then the natural question is asked: why even walk on the roof in such heat? In fact, there are reasons: to fix the antenna, remove a mischievous cat, return a flying drone.

Don't forget about wind loads too. Yes, and Ondulin and corrugated sheets have similar geometric surfaces and, like solid materials, have high windage properties. But corrugated sheeting is still torn off roofs more often. Why?

The fact is that, due to this very problem, ondulin manufacturers produce special nails with wide heads and threads on the rod. The nail is driven deep into the sheathing, where it sits quite firmly, and the wide head of the fastener holds the sheets well. But with corrugated sheets, standard screws are used. And their cap is not as wide as that of ondulin.

Heat shielding: comfort of living under a roof

This is how a bitumen profiled sheet fundamentally differs from a metal one:

Bitumen is a natural resin, and ondulin has always had and will have a certain flexibility and viscosity at high temperatures. Therefore, on the hottest summer days it softens a little, which causes inconvenience, if only because walking on such a roof is temporarily not allowed. But at the same time, bitumen sheets themselves have low thermal conductivity, and therefore do not transfer heat to the under-roof space.

Thanks to this, the attic or residential attic with such a roof is cool in summer and warm in winter. The same cannot be said about a metal roof, which heats up in direct sunlight in a matter of minutes, and in winter turns into ice. At the same time, the presence of a layer of insulation under the sheets only partly solves the problem.

Protective coating: weathering

Modern ondulin on the front side of the sheet is covered with a protective and decorative paint layer based on light-resistant pigments and polymers. High-quality ondulin is also coated with high-strength acrylic, which significantly increases the durability of the sheets and protects them from weather conditions. Thanks to all this, all the dirt that gets on the roof surface can be easily removed by the first rain or sliding snow.

By the way, the surface of ondulin is rough, and therefore by itself holds a cap of snow on the roof (additional thermal insulation, by the way). But for corrugated sheeting you need to install special snow guards, and the more, the better:

As you can see, this is very close in properties to the perfectly smooth surface of a corrugated sheet, on which dirt almost never lingers.

Condensation problem: rain under the roof

And not only do the drops collect on the inner surface of the panel, but they also roll directly onto the walls. And therefore, when laying insulation, it is necessary to create a ventilation gap and provide ventilation so that all moisture leaves the roof and does not spoil the thermal insulation.

At the same time, ondulin does not heat up that much, and therefore does not condense, and there is no question of such problems. True, it softens from the sun's rays and some residents even detect the smell of bitumen.

But, in fairness, we note that there are brands of corrugated sheets that are produced with a special anti-condensation coating on the inside. This decision was literally revolutionary. The fact is that before sale, corrugated sheets often have to be stored in cold rooms, and since the metal cools faster than other materials, even from the cold air there is something to condense on its surface.

The anti-condensation coating itself is something like a pile that holds small drops on itself, preventing them from collecting into small streams. And when temperature conditions return to normal, the coating will dry on its own in the air flow:

Interestingly, the polymer film on such corrugated sheeting also protects the metal itself from negative chemical influences, of which there are many, for example, in industrial buildings.

All this is important for industrial construction. After all, the mere use of accompanying material in the form of additional boards and waterproofing increases the labor intensity of all work at least twice. As is their cost.

Until recently, condensation on corrugated sheets was dealt with using standard technological solutions. Rolled waterproofing or roofing membrane was spread over the sheathing, a gap was made, then the roof covering itself was fastened along the counter-lattice. Moisture from the air condensed on the inside of the metal sheet, then dripped onto the waterproofing and simply flowed down it if everything was done correctly.

This is a simple physical phenomenon: there is always water vapor in the air, and when heated, it comes into contact with a colder surface and simply cools down, turning into droplets, at a moment called the dew point. Moreover, this process occurs every day, every night. Considering that during the day the metal roof is heated by the sun and heats the air under it.

If it now seems to you that corrugated sheeting is definitely inferior to ondulin, let’s honestly and impartially consider the important disadvantages of the latter:

Let us add the following observation regarding color fading. G glossy ondulin becomes beautifully matte after a year or two, lighter in tone and most buyers even like it.

Transportation and installation: pitfalls

Ondulin is quite easy to transport due to its light weight (up to 6 kg). You've probably seen a stack of bitumen sheets on the roof of a car or in the trunk. But, due to the fact that ondulin can be bent, putting it in the trunk will not be a problem, but corrugated sheeting can only be transported on the roof of a car, or even using special transport.

Further, if it is difficult to scratch ondulin sheets during loading and unloading, then the corrugated sheet can begin to rust from the slightest damage. What is the disadvantage of corrugated sheeting? In the process of transporting parts to the construction site, you literally have to shake over metal sheets.

After all, even if you then treat the scratches with paint or sealant, it will become noticeable and the original appearance of the roof will be lost. That’s why such sheets are also lifted onto the roof with extreme caution.But you can even throw ondulin onto low buildings by hand.

Unfortunately, some of the typical problems with corrugated sheets arise even before installation:

Installation Features: Geometry Problems

There is a significant difference in the installation of corrugated sheeting and ondulin. Thus, ondulin can be laid on roofs with a slope of at least 14 degrees. But corrugated sheeting, depending on the height of its corrugation, is even suitable for constructing a load-bearing floor for a house. To some extent, certain types of corrugated sheeting are much more durable and stronger than ondulin (which cannot be said about metal tiles).

When the roof is perfectly flat, both bitumen and metal profiles will look decent on it. But if it turns out that the slopes are not even rectangles, then things are bad.

To check this, you do not need to make cuts in the eaves and gable boards. It is enough to measure the diagonals, and they should match. If it turns out that one diagonal is larger than the other, you have problems.

After all, metal sheets, unlike bitumen ones, cannot be stretched, compressed, or “pulled” to the desired location. You will have to sacrifice another sheet to cut out two triangles from it, and place each on the sides of the slope - where it will be empty and where the error in the rafter system will be clearly visible. What the roof will look like after this is another question.

But with ondulin, these problems can be easily solved with your own hands:

By the way, ondulin is quite flexible and by itself slightly eliminates the problem of sloppy sheathing. But don’t let this reassure you, because we are still talking about building a roof. At the same time, with corrugated sheeting, any error will be clearly visible.

By the way, ondulin is quite flexible and by itself slightly eliminates the problem of sloppy sheathing. But don’t let this reassure you, because we are still talking about building a roof. At the same time, with corrugated sheeting, any error will be clearly visible.

This suggests that even an unqualified builder is able to cover a roof with ondulin quite efficiently, just by carefully studying the instructions and advice on our website. This is an important point, because there really aren’t that many trained, experienced roofers. And the more complex the installation technology, the higher the risk that it will be messed up.

Let's also consider such an important point as cutting roofing sheets. You still need to try hard to ruin an ondulin roof, and you can even cut bitumen sheets with an ordinary stationery knife. The only thing is that you can cut Euro slate in the summer only in the morning or evening so as not to soften it.

But cutting sheets of corrugated sheets in an open area is not a difficult task. True, if you do this in direct sunlight, the metal will heat up to an unpleasant temperature, giving harsh radiation directly to working people.

One of the most pressing problems is mounting the fastener. It only takes a little extra force to damage the rubber gasket on the screw. But in the case of bituminous material, you can safely work with a hammer - the base is soft and pliable, and the edges of the cap are more likely to slightly bend it than to deform themselves:

This is an important point. After all, it is precisely because of small jambs in the installation of corrugated sheeting that 99% of problems arise with it in the future: it corrodes, leaks and loses its appearance!

You should also take into account the fact that, if necessary, the corrugated roof can be carefully dismantled and moved to a new location. But in the case of ondulin, you will have to throw it away, because... the nails in it, of course, can be pulled out, but the appearance of the ondulin itself will not be the same - there will be torn holes in the places after fastening.

In total, the manufacturer of ondulin, like corrugated sheeting, produces all the necessary additional elements for the roof.

Which material did you like best? Tell us about your choice!

No matter what a person builds, a toilet in the far corner of a summer cottage or a three-story cottage, one always has to look for the answer to the question of how to cover the roof.

In general, there is something to buy on the construction market, both for the gazebo and for the house. Some people can afford something that is more expensive, others need to find something that is cheaper.

Some are guided by certain criteria of reliability and strength, others are guided by color... Most often, an ordinary resident building his own house faces a choice between ondulin and corrugated sheeting.

What is ondulin? A roofing material that appeared relatively recently on the CIS markets was invented and began to be produced in Europe about 50 years ago. Due to its external similarity to the asbestos slate we are used to, ondulin is sometimes called Euroslate.

This “slate” is made from waste paper. It is crushed, mixed with water and dyes until a homogeneous mass is obtained, which is passed on a conveyor through a molding machine, where it takes the form of wavy, slate-like sheets.

Then these sheets are dried and impregnated under pressure and high temperature with distilled bitumen with the addition of synthetic resins and mineral additives.

The positive characteristics of ondulin usually include:

- Flexibility and light weight (about 3 kg/m2)

- Ease of use - easy to cut

- Safety for humans and nature

- Quiet material

- Durability -40 - 50 years of service

- Affordable price

Negative qualities are considered:

- Few colors (red, brown, green, lilac)

- Burnout

- Low fire resistance

- Brittleness in cold weather and excessive softness in hot weather

Not all statements are certain. It's easy to cut, but you'll have to throw in a hacksaw. Burnout is also questionable. The author of the article has had a house covered with ondulin since 2010. Brown. No burnout is visible.

Fragility and softness can be tested, but why? The roof is divided to protect from snow, wind and rain, and not to jump on it.

And if the house catches fire, then what difference does it make, in principle, whether the ondulin burns or not?

Corrugated sheets are produced by cold rolling of steel sheets. The result is a wavy profile, but the waves are not round in shape, like those of ondulin, but trapezoidal.

At the same time, the height of the “trapezoid” can be different, so corrugated sheeting is conventionally divided into “low profile”, “medium profile” and “high profile”.

Corrugated sheets are produced galvanized and coated with colored polymers.

Pros of a profiled sheet:

- Lightness (from 4 to 8 kg/m2)

- Ease of use during installation

- Environmental friendliness

- Service life up to 50 years

- Fire resistance

- Affordable price

- Increased noise

- Gets very hot in the sun

- Possibility of condensation

- Susceptibility to corrosion

Here, too, one can argue... On the one hand, a sheet of large area eliminates the presence of joints and overlaps, as when using ondulin, on the other hand, it is necessary to “catch” calm, windless weather, which is not always possible.

Otherwise, a gust of wind may simply tear the leaf out of your hands. It's good if it ends with minor bruises. Regarding fire resistance, it also does not play a special role when a house is on fire.

“With all the wealth of choice, is there no other alternative?”

It is clear that the “positive” and “negative” properties of ondulin and corrugated sheets are very conditional things. Burnout of ondulin in the sun is possible if you come across a fake.

Real ondulin is impregnated with paint at the raw material preparation stage, and is not painted on top with regular paint. Some people actually like the sound of rain.

Yes, and sound insulation can be provided at any time, fortunately, there are many materials for this. Metal can be protected from corrosion by properly and promptly processing the cut lines.

On the other hand, there is also the concept of “prestige”. For some, a roof covered with corrugated sheeting with a polymer coating will look “richer” than a roof covered with ondulin.

In general, the obvious conclusion is that the choice is not obvious.

Having familiarized yourself with all the information about a particular roofing material, the technology of its manufacture, its physical, mechanical and technical characteristics, color palette, everyone can take for themselves something that will not cause disappointment after several years of life under the chosen roof.