Metal tiles are an engineered “fusion” of steel strength and the aesthetics of traditional ceramic roofing. Lightweight profiled sheets have virtually no effect on the weight of the structure and delight installers with their convenient dimensions.

A sure plus in the collection of material priorities is the ability to independently carry out the entire cycle of roofing work without the paid participation of builders. Just first you need to find out how to construct a metal tile roof with your own hands, and learn about the rules and subtleties of the process of its installation.

The corrugated metal sheets of the currently popular coating are equipped with double protection against atmospheric attacks. Steel profiled blanks are first immersed in containers with hot zinc, due to which an anti-corrosion film is formed on the surface. Then the outer side of the material is covered with a colored polymer shell, which performs aesthetic and protective functions.

However, both degrees of protection will not be able to withstand the attacks of precipitation and household fumes if the roofing pie is constructed with violations and errors. Condensation will begin to accumulate in the space under the coating, which will slowly but surely reach the metal. The insulation will become moist and lose its insulating properties. The wooden elements will get wet and rot as a result.

You shouldn’t completely rely on the light weight and impressive area of sheets of material either: the rafter system must be strong enough, and the sheathing needs to be such that each element is fixed at the required number of points. Therefore, you should properly prepare for the independent installation of metal tiles, i.e. become familiar with the nuances of constructing a rafter structure, sheathing and roofing pie.

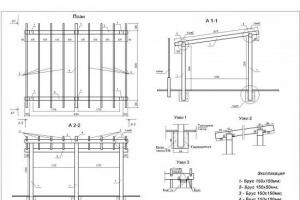

Rafter system and sheathing

Metal tiles are used in the construction of cold and insulated roofs. The rafter system for the cold type can be constructed from steel or aluminum elements. But wood is still a priority, because it is easier to attach covering sheets to it. Insulated structures require stronger rafter trusses, because thermal insulation will be located between their legs. The use of metal in such situations is impractical, so warm roofs are installed on wooden rafters with sheathing.

Note that metal roofing is possible on pitched roofs with a minimum slope slope of 14º. The optimal roof slope is considered to be from 15º to 20º.

The construction of a rafter system for a warm roof with metal tiles has its own rules, these are:

- The step between the rafter legs should not exceed 90cm. The minimum distance between rafters is 60cm. If the pitch of the existing rafter system is greater than the specified upper limit, an additional sheathing is installed from a transversely installed board.

- The rafter system is made of 50mm thick boards. The recommended board height is 100 or 150mm depending on the thickness of the thermal insulation.

- When laid in the spacer between the rafters, it should not come into contact with traditional waterproofing. If the thickness of the insulation is equal to the transverse height of the board used in the construction of the rafter structure, then an additional counter batten measuring 30×50 or 50×50 is placed on the rafters along their direction. It will create a gap of 3-5cm.

In order to ensure ventilation of wooden elements, it is advisable to drill holes Ø 2-2.5 cm in the side rafter legs. Forming holes is an optional procedure, but strongly recommended by metal tile manufacturers. If there are concerns about the weakening of the structure, it is recommended to place them closer to the ridge in two or three rows with a step of 30 cm.

Before constructing the lathing, which acts as a basis for fastening sheets, you should check the geometric parameters of the rafter system. The lengths of the diagonals of the rectangular slopes should be measured and verified. On mansard roofs, the lengths of the diagonals of each part of the slope are separate. You need to check the horizontality of the overhangs and ridge, as well as the location of the outer surface of the rafter legs in the same plane. Timely identification of deviations in geometry will eliminate further errors.

Having convinced yourself of the geometric perfection of the trusses, you can begin to construct the sheathing, the construction of which, by analogy, has clear rules:

- The first batten - the lowest batten on the overhang should be higher than the subsequent row battens. To construct it, you need to take a block thicker than for ordinary laths. For example, for the bottom rail it is 50x50, and for all subsequent ones it is 30x50.

- The initial batten of the sheathing should be clearly parallel to the eaves line.

- The step between the first and second bars is 28 or 30 cm. The step between subsequent slats is 30, 35 or 40 cm. the pitch is determined by the distance between the transverse waves of the metal tile.

- During the installation of sheathing, through penetrations through the roof are taken into account and fastening devices for pipes are installed.

- In the gutters, around roof windows, chimneys, fan pipes and other pipes, a continuous sheathing of boards is installed.

- At the top of the slopes, two boards are nailed to the rafters to ensure reliable fixation of the eaves strip. The boards are installed at a distance of 5 cm from each other.

Among other things, before installing the sheathing, all wooden components should be treated with an antiseptic and fire-retardant compound.

The lathing not only plays the role of a basis for fastening sheets, but at the same time performs another very important job. It forms ventilation channels through which air flows circulate from the overhang to the ridge, and provides a ventilation gap between the waterproofing layer and the coating.

Ventilation ducts must remain free so that air can flow under the metal sheets and exit without interference. On the side of the overhangs and on the side of the ridge, they are simply covered with perforated tape, which prevents dust and debris from getting into the roofing pie.

Structural roofing boards

Eaves boards are used to strengthen the slope and make it more rigid if the roof is planned to be equipped with an organized drainage system or the overhangs are hemmed with vinyl siding. In situations where the hemming is done simply with a board, there is no need to use board reinforcement.

The eaves boards are laid along the overhangs in the grooves pre-selected in the rafters. The dimensions of the grooves must correspond to the dimensions of the board so that the overhang plane remains unchanged and the height of the rafter system does not increase. If you plan to install long hooks used to fix the gutter, grooves are cut out in the eaves board for their fastening. Hooks with a short leg are screwed only to the front board. They are used when the installation of a drainage system was not planned in advance and when repairing old roofs. The installation step of all types of hooks is equal to the step of the rafter legs.

A front board is used if the roof does not have an organized drainage system. It is attached to the ends of the rafters with galvanized nails. Serves as an element for fastening various roofing parts and accessories, including for hemming overhangs. The end board serves as the basis for the end strip, the latter covers the waterproofing laid on top of the board. In addition to its decorative function, the strip nailed to the end board prevents rattling of the roof.

Time to hem the overhangs

Coating manufacturers strongly advise lining overhangs with valves specially produced for this purpose, for example KTV or Vilpe. Siding, corrugated sheets or vinyl soffits are recommended for filing cornices. The extensions are sold complete with connecting parts and instructions. You can economically hem it with a board attached with a gap for roof ventilation.

Specifics of the roofing pie

The composition and structure of the roofing pie for metal tiles depends on whether the structure will be insulated or not. In the simplest non-insulated scheme, only a waterproofing film is used. A vapor barrier is used if the attic space is to be hemmed.

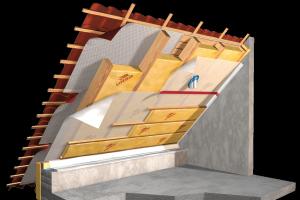

The insulated roofing pie includes three standard layers, these are:

- Vapor barrier. It is located on the side of the future intake of household fumes, i.e. from inside the rafter system. Its job is to protect the insulation from steam. Strips of vapor barrier material are laid parallel to the overhangs with an overlap of 10-15 cm. They are attached to the rafters with a stapler, and connected into a single sheet with adhesive tape. A gap should be created between the interior lining of the attic and the vapor barrier by installing sheathing.

- Thermal insulation. Mineral wool boards are most often used as insulation, the thickness of which is determined in accordance with the requirements of SNiP II-3-79. The material is installed between the rafter legs. To ensure rigidity of installation, the slabs are cut 1.5-2 cm wider than the distance between the rafters.

- Waterproofing. It is needed as a barrier against precipitation. They lay it on the outside of the rafter system before installing the sheathing; they try to install it immediately after laying the insulation, so as not to get wet. The waterproofing material is laid like a vapor barrier, in strips with similar overlaps and fastening methods.

The waterproofing layer is laid so that its sheet overlaps the perimeter wall lines by at least 20 cm. In areas where slopes meet and in valleys, laying is done with overlaps of 20-30 cm. The waterproofing must have a gap along the ridge line so as not to interfere with air circulation.

Important condition: bitumen water-repellent materials cannot be used as waterproofing of the roofing pie when installing a metal tile roof. Waterproofing must allow steam and condensation accumulated in the insulation to pass through.

The method of installing a water-repellent layer depends on the material used:

- The classic version of waterproofing is reinforced or unreinforced polyethylene film, which must be provided with two ventilation gaps. The first of them is formed by the rafter system and is located between the insulation and the film, the second is formed by the lathing and is located between the film and the roofing. The size of each gap is 3-5cm.

- The superdiffusion membrane can work perfectly with one ventilation gap 3-5cm wide. It is created between the membrane and metal tiles. When using a polymer material, there is no point in breaking the contact between the waterproofing and the insulation. After all, the membrane is capable of allowing excess moisture to pass out, preventing it from getting inside.

- Anti-condensation materials with a fleecy surface designed to accumulate moisture. Their pile is quickly ventilated when washed with air, which should be provided with a path. Therefore, this option also requires dual-circuit ventilation, like the classic. It is used mainly in the construction of cold roofs.

All types of insulating materials, except polymer waterproofing, are laid with sagging. This is necessary so that the film does not tear when tensioned. Only the membrane does not need to be laid with sagging - it has the property of stretching.

Around through passages through the roof, waterproofing is applied to the walls of communication pipes by 5-7 cm. Ideally, it is recommended to install an additional waterproofing layer around pipes and other weakened areas of the roof.

Installation of parts before laying the covering

Before laying metal tiles, the following must be installed:

- Eaves strips that prevent dust and debris from penetrating into the under-roof space. They are mounted on top of the ventilation tape attached to the ends and the legs of the drain hooks. The planks are attached to the front and cornice boards with self-tapping screws in 30cm increments. To prevent rattling from gusts of wind, these metal parts are installed with interference.

- Cornice drips, which are located under the waterproofing film. They are needed to remove moisture from the waterproofing.

- A lower valley that enhances protection for concave roof corners. It is a metal corner that follows the shape of the groove. Mounted on top of a continuous plank sheathing. The lower edge of the corner is located above the cornice board. In almost flat valleys, the boardwalk is equipped with an additional strip of waterproofing. The lower valley is screwed with self-tapping screws every 30cm. A porous seal is laid over the lower valley.

- Protective edge around chimney pipes crossing the roof. It is carried out using metal contour strips, the upper edge of which is attached to a groove formed in the pipe walls and treated with sealant. Drilling into the seam is prohibited! The same rules apply when arranging junctions with walls.

- A lightning rod required for the safe operation of a metal roof.

The lightning rod system consists of three main parts. The first is an lightning rod, which is a steel or aluminum rod Ø 12 mm with a length of 20 cm to 1.5 m. The second component of the down conductor is a single-core steel or aluminum wire Ø 6 mm welded to the lightning rod. The down conductor is laid along the sheathing and along the walls, leading to grounding. Grounding, the third part of the system, is an iron beam 1.5 m long buried at a depth of 1.5 m or a steel sheet with an area of 1 m × 1 m, for example.

Rules for laying metal tile sheets

Before laying the profiled sheets, it is necessary to arrange logs for transporting the material to the roof. In order not to lift the covering one sheet at a time, it is advisable to build racks for temporary storage. The home handyman will also need soft shoes, diligence and accuracy when moving on the roof. The work performer is only allowed to step into the deflections of the profiled waves.

When laying metal tiles, you can move either to the left or to the right from the first fixed sheet. The main thing is that the sheet laid on top overlaps the capillary groove. The guideline for choosing the laying direction is convenience. However, it is better to proceed in such a way that the element laid on top is immediately placed under the outermost wave of the previous one and snapped into place with a capillary groove. This will keep it in place and prevent it from slipping.

Typical installation sequence

Indisputable rules for installing metal tiles:

- The starting sheets are attached to the first lath through a wave on top of the transverse step of the coating. Their lower edge extends 5cm beyond the cornice.

- All subsequent fastenings of sheets are carried out in the recessions of the waves from the bottom of the transverse step.

- Along the end board, a profiled covering is attached in all waves.

Before fastening, you must carefully check the horizontal position of the sheet. After making sure that the installation is perfect, it is temporarily secured with one screw at the top edge in the center. Then lay the second sheet, level it and temporarily fix it in the same way. The aligned sheets are fastened together. Do the same with the third and fourth.

Screwing to the sheathing is carried out when a block of 3-4 sheets is laid and temporarily secured. Fix the block at all specified points. Only the outermost sheet is not screwed to the sheathing, so that it remains possible to connect it with the subsequent element.

The process of laying metal tile sheets in several rows differs only in that the rows of material must also be fastened to each other. Sheets increase in height vertically.

Profiled sheets are suitable for pitched roofs of any configuration. However, to properly install a hip or hip roof made of metal tiles, you will have to act according to a different scheme.

Installation of sheets on triangular slopes:

- We find the center of the overhang and draw the central axis through it.

- We take the first sheet and do the same actions with it.

- We combine the axes of the slope and the sheet in fact, checking the horizontal and vertical.

- Temporarily secure the sheet with a self-tapping screw in the center at the top edge.

- We install the sheets to the right and left of the central covering element using the usual method.

After attaching the corrugated sheets, the excess is trimmed off.

Convenience of cutting with marking of material for arranging valleys, triangular, trapezoidal and oblique slopes will be provided by a homemade “devil”. It is constructed from four boards 10 cm wide. The boards are arranged in parallel pairs and connected to each other according to the hinge principle. A simple device will help you accurately outline the segments to be cut.

Final installation work

After laying the wavy coating, you can begin with the finishing touches with a light heart:

- Install passage elements around pipes, antennas and other communications. All components of the roofing pie at the intersection points are sealed with adhesive tape. Butt seams are filled with sealant.

- Screw the end strip to the end board with self-tapping screws every 50-60cm.

- Screw on the top valley strip, first laying a self-expanding seal on the covering.

- Build a skate. To do this, the outside of the ridge area is covered with Metalroll or Figarol waterproofing. Ventilation ducts must remain open. The ridge is fixed to the sheathing with self-tapping screws; the fasteners should be screwed through the convex ridge. The ends of the ridge element are closed with plugs.

A drainage system, snow retainers, ladders for maintenance and fencing, if planned, are installed over the laid covering.

A detailed video instruction will be an excellent way to consolidate information about installing a durable metal roof on a roof with your own hands:

There are many nuances in installing a roof with metal tiles. However, there is nothing super complex in the technology. It is necessary to become familiar with the intricacies of the device and follow them so that you do not have to change the roof again to the next option.

Metal tiles are roofing materials based on galvanized steel with a wavy profile that imitates the shape of ceramic tiles. It is one of the most popular materials for roof construction. Construction stores offer a wide selection of all the accompanying elements for creating a roof made of metal tiles (ridge profiles, valleys, eaves, gable strips) to do the roofing work yourself. In this article we will tell you what the technology of installing a metal tile roof looks like.

Metal tiles are a roofing covering based on galvanized steel with a polymer or paint layer, used for the construction of cold or warm roofs. It is produced by cold rolling from steel billets. The strengths of metal tiles are:

- A light weight. One square meter of metal tiles weighs 5.5-6.5 kg, which makes it possible to install them on thin lathing without reinforcing the roof rafter frame.

- Long service life. High-quality metal tiles, as well as additional elements made of galvanized steel, can be used for more than 20-25 years with proper maintenance and timely repairs.

- Corrosion resistance. The zinc layer and polymer coating reliably protect the steel from exposure to water, so the metal tiles are not subject to corrosion.

- High load-bearing capacity. Thanks to the wavy profile, metal tiles have high load-bearing capacity and do not deform under intense loads.

- Resistant to temperature changes. Temperature changes do not affect the strength properties and integrity of the material, so it is used in all climatic zones.

Important! It is recommended to lay metal profile coverings on single-pitched and multi-pitched roofs with a slope of at least 12 degrees. To install a cold roof, you will need the roofing material itself, as well as additional elements: valleys, ridges, eaves or gable strips, drainage elements, soffits for filing eaves, lightning protection, snow retainers. The design of a warm roof involves the additional use of insulation and vapor barrier.

Selecting elements

– multi-layer structure, the elements of which interact with each other, increasing its quality and service life. The structure of a cold roof consists of waterproofing, sheathing and roofing, while a warm roof also includes a vapor barrier and a layer of insulation. Experienced craftsmen recommend choosing materials for roofing in accordance with the following criteria:

- When choosing metal tiles, only 2 indicators play a role - the height of the corrugation and the thickness of the steel. The higher these indicators are, the greater the strength and load-bearing capacity of the roofing covering. The required number of sheets is calculated based on the area of the slopes and the usable area of the canvas.

- Additional elements, such as cornice and gable strips, are purchased depending on the footage of the overhangs, taking into account an overlap of 15-20 cm. They are selected to match the metal tiles.

- Valleys are used to equip joints between slopes in multi-slope, complex structures. They are steel strips in the form of a corner with a polymer coating.

- The ridge profile is used to equip the roof ridge. Ridge elements, like valleys, are corners with fastening shelves of 20-50 cm. The wider the shelves, the better the profile protects the gap between the sheets of material from moisture penetration.

Please note that the design of a warm roof is much simpler than a warm one, since it consists of only 3 layers. However, roofing components are used to construct any type of roof. High-quality additional elements help maintain the integrity of the roofing sheet when equipping junctions with vertical and horizontal surfaces, the passage of pipes and aerators through the slope, minimizing the risk of leaks.

Roofing pie

The basis for the durability and reliability of the roof is a well-composed roofing pie made from compatible materials, which provides an airtight and durable coating. The roof structure made of metal profiles has a multi-layer structure that performs 4 important functions: waterproofing, thermal insulation, vapor barrier, wind protection. The roofing pie for metal tiles consists of the following ingredients:

- Vapor barrier. It protects the rafter frame from the penetration of steam saturated with moisture from the heated rooms of the upper floor or attic. Vapor barrier is a diffuse membrane that allows air to pass through but does not allow water to pass through; it is attached to the lower surface of the rafters with a construction stapler.

- Thermal insulation. The insulation is installed between the rafters of the roof frame. The thermal insulation layer required to maintain optimal temperature conditions is calculated based on climatic conditions. The design of a cold roof does not include insulation.

- Waterproofing. Waterproofing material is laid over the rafters to protect the wooden frame elements from moisture penetration from the outside. Film or membranes are used as waterproofing. For the installation of a cold roof, the use of roofing material is allowed.

- Counter-lattice. Slats 2-3 cm thick, laid along the rafters, form a counter-lattice, which forms a ventilation gap between the layers of the roofing pie.

- Lathing. The metal tiles are mounted on a lattice sheathing, fixed perpendicular to the rafters. This structural element is responsible for distributing the weight of the roofing and imparting rigidity to the slopes.

Please note that the instructions require the use of auxiliary elements that form a sealed coating, protected from moisture penetration on all sides. If you install a metal tile roof using valleys, a ridge profile and various abutment strips, then there will be no leaks even during heavy rainfalls.

Lathing requirements

It is carried out on a solid base - lathing. Sheathing is a flooring made of wooden boards or bars laid with a gap to which the roofing material is attached. The sheathing elements must support the roofing sheet in 3 places to prevent deformation: on the sides of the sheet and in the center. The following requirements apply to the lathing:

- The instructions require installing lathing for metal tile flooring in increments of 30-50 cm, depending on the wavelength of the roofing covering.

- Wood for the manufacture of sheathing is treated with antiseptic and fire-blocking compounds to protect it from rotting and increase resistance to fire.

- In places where valleys, ridge profiles or snow retainers are attached, the sheathing is reinforced with an additional element. This is done because valleys and other valley elements are places where liquid and snow accumulate, so the load on the rafters is higher there.

Experienced craftsmen say: the flatter the roof slopes, the smaller the pitch of the sheathing should be. This instruction is explained by the fact that from roofs with a small slope, liquid and snow do not slide off on their own, but are retained, as a result of which the load on the rafters and sheathing increases.

Laying technology

The laying of metal tiles is carried out after the assembly of the rafter frame and sheathing is completed. To avoid getting the wooden frame elements wet, installation should be carried out in dry weather. For safety reasons, it is prohibited to carry out work at height in windy weather. To lay the metal profile with high quality. There is the following instruction:

- Waterproofing material is laid on top of the rafters, starting from the roof overhang. Laying is done with a slight sag so that the waterproofing does not burst under water pressure. The film is attached to the rafters with a stapler; an overlap between the strips is made of 10-15 cm, gluing it with adhesive tape.

- Counter-lattice slats are installed along the rafters directly on top of the waterproofing, which form a ventilation gap necessary to protect the roofing material from condensation.

- Then, perpendicular to the rafter legs of the frame, the lathing is fixed to the counter-lattice with a step equal to the wavelength of the metal profile.

- Metal tile sheets are cut to fit the dimensions of the slope. If you buy the material directly from the manufacturer, then the cutting is done at the factory, so there will be no horizontal joints between the sheets. You can cut metal profiles outside of production with a circular saw, jigsaw or hacksaw.

- Begin laying from the lower right edge of the slope. If laying is done in one row, then the sheets are attached one after another. If the installation is carried out in 2 rows, then first lay the outermost sheet at the bottom of the slope, then fix the sheet above it, then the 2nd sheet of the first row, and so on.

- The sheet is attached to the sheathing using roofing screws with a rubber press washer, which closes the fastening hole from water penetration. The screws are screwed in strictly at right angles to the surface of the roofing material, leaving a gap of 1-2 mm so as not to deform it. To fix 1 sheet, 10-15 screws are required.

- During installation, metal tiles overlap each other by 1 wave. The place where the sheets overlap is fixed with self-tapping screws through a capillary groove.

Note! When fixing metal tiles, it is important not to twist the self-tapping screw to avoid deformation of the material and chips on the polymer coating. To do this, it is better to use a screwdriver at low speeds.

Installation of additional elements

The installation of a metal roof does not end with laying the roofing material. To make the structure more durable, protected from atmospheric moisture and complete, it is necessary to install valleys, a ridge profile and cornice strips. The work is performed in the following order:

- Install the ridge profile. It is attached to the sheathing along the ridge connection with roofing screws. To protect the ends of the profile from water ingress, a special seal is used.

- Fix valleys and other valley elements. To protect the joints between the slopes and the junctions with vertical surfaces, special strips are installed.

- Eaves and equipped with special strips that protect from moisture and wind.

- The eaves and gable overhangs are covered with soffits. These perforated panels protect the lower surface of the slope, not protected by waterproofing, from contact with water.

- Install drainage, snow barriers and lightning protection.

Remember! Valleys, ridges, junction strips and gutters are not decorative elements of the roof. They perform the function of protecting the canvas from leaks, sealing it. Provided the roofing pie is properly equipped and auxiliary components are used, a metal tile roof will last 20-30 years.

Video instruction

The popularity of metal tiles in roofing is explained by its availability and relatively simple installation technology. Metal roofing has excellent performance characteristics and is suitable for roofs of any configuration. Compliance with all requirements when laying such a coating guarantees its long service life. Proper installation of a metal tile roof will provide reliable protection of the roof space and living quarters from precipitation. Almost all manufacturers of metal tiles and roofing accessories provide buyers of their products with detailed manuals and technical instructions for the correct installation of metal tile roofing. The basic principles of installation work are identical, however, there are separate recommendations for specific products. When considering the issue of installing a roof made of metal tiles, you need to decide what the principle of its insulation will be, whether the roof will be cold or warm.

The construction of a metal roof in some aspects depends on the principle of its insulation. There are two main types of roofing – cold and warm. In the first case, we are talking about insulating only the interior of an attic or non-residential floor, despite the fact that the outer part of the metal tile roof is not equipped with thermal insulation. In this case, the design of the slopes provides for natural ventilation, which prevents the formation of condensation from temperature differences. A warm roof, unlike a cold one, requires the formation of a multi-layer thermal insulation layer. The design of a warm roof allows you to equip an attic residential floor, since its thermal insulation qualities will be an order of magnitude higher than a cold roof. The so-called pie of a warm roof made of metal tiles must be formed from a layer of vapor barrier, a thermal insulation material that is placed between the roof joists, and a waterproofing membrane that serves as an obstacle to condensation from the back side of the metal tiles getting onto the thermal insulation. The vapor barrier film serves as protection against fumes from the inside of the room.

The construction of a metal roof in some aspects depends on the principle of its insulation. There are two main types of roofing – cold and warm. In the first case, we are talking about insulating only the interior of an attic or non-residential floor, despite the fact that the outer part of the metal tile roof is not equipped with thermal insulation. In this case, the design of the slopes provides for natural ventilation, which prevents the formation of condensation from temperature differences. A warm roof, unlike a cold one, requires the formation of a multi-layer thermal insulation layer. The design of a warm roof allows you to equip an attic residential floor, since its thermal insulation qualities will be an order of magnitude higher than a cold roof. The so-called pie of a warm roof made of metal tiles must be formed from a layer of vapor barrier, a thermal insulation material that is placed between the roof joists, and a waterproofing membrane that serves as an obstacle to condensation from the back side of the metal tiles getting onto the thermal insulation. The vapor barrier film serves as protection against fumes from the inside of the room.

Lathing

One of the most critical stages of arranging a metal roof is the formation of the sheathing. The assembly diagram of this structure is essentially the formation of the frame of the future roof, and the performance qualities of the entire roof depend on its correct equipment and installation. The installation of a roof for metal tiles can be divided into the following successive stages:

The installation of a roof for metal tiles can be divided into the following successive stages: - erection of rafters;

- waterproofing film flooring;

- arrangement of counter-lattice;

- sheathing.

- covering with metal tiles.

The sheathing itself is mounted directly on top of the counter-lattice. For its construction, wooden blocks of 5×5 cm or 3.2×10 cm are used. They must be treated with wood antiseptics to protect against rotting, fungus or mold. A prerequisite is to strengthen the sheathing in the area where the ridge is located. It is ensured by connecting the last two bars.  The distance between individual sheathing boards, or the so-called pitch, is determined depending on the selected type of metal tile. The instructions for a particular roofing profile contain detailed information about this indicator, as well as the size of the step in the eaves of the roof slope. Thus, for Cascade metal tiles, it is necessary to ensure a sheathing pitch between the first and second bars of 250 mm, between the second and third - 350 mm, and for subsequent ones - 300 mm. When installing Monterrey-type metal tiles, the step between the first and second lathing should be 300 mm, and between subsequent ones 350 mm. Metal tiles of the Elite type provide for a sheathing pitch of 350 mm between the first and second rows and 400 mm between subsequent ones.

The distance between individual sheathing boards, or the so-called pitch, is determined depending on the selected type of metal tile. The instructions for a particular roofing profile contain detailed information about this indicator, as well as the size of the step in the eaves of the roof slope. Thus, for Cascade metal tiles, it is necessary to ensure a sheathing pitch between the first and second bars of 250 mm, between the second and third - 350 mm, and for subsequent ones - 300 mm. When installing Monterrey-type metal tiles, the step between the first and second lathing should be 300 mm, and between subsequent ones 350 mm. Metal tiles of the Elite type provide for a sheathing pitch of 350 mm between the first and second rows and 400 mm between subsequent ones.  It is also worth paying attention to the fastening of the counter-lattice elements to the rafters. In this case, experts recommend laying a tape made of foamed polyurethane or polyethylene between the vertical bars of the counter-lattice and the rafters. Such a gasket is necessary to absorb possible slight deformation of the rafters due to drying out of the wood and subsequent damage to the structure of the counter-lattice and the integrity of the waterproofing layer. All components of the sheathing are fixed with nails. Experts, taking into account practice and personal experience, recommend using galvanized nails. Fastening the sheets of metal tiles begins from the lower right corner of the slope. The first sheet is carefully aligned in all directions and fixed to the sheathing with only one screw in the upper part. Next, another sheet is laid parallel to the fixed one. Both panels are fastened together with self-tapping screws. After this, the sheets are once again carefully aligned along the cornice and finally fixed to the sheathing using self-tapping screws with rubber gaskets. Further laying is carried out by overlapping part of the new sheet onto the already fixed one. Also, many craftsmen stack sheets from left to right, slipping the next sheet into the lock of the previous one. This way you can achieve more precise joining of sheets in locks.

It is also worth paying attention to the fastening of the counter-lattice elements to the rafters. In this case, experts recommend laying a tape made of foamed polyurethane or polyethylene between the vertical bars of the counter-lattice and the rafters. Such a gasket is necessary to absorb possible slight deformation of the rafters due to drying out of the wood and subsequent damage to the structure of the counter-lattice and the integrity of the waterproofing layer. All components of the sheathing are fixed with nails. Experts, taking into account practice and personal experience, recommend using galvanized nails. Fastening the sheets of metal tiles begins from the lower right corner of the slope. The first sheet is carefully aligned in all directions and fixed to the sheathing with only one screw in the upper part. Next, another sheet is laid parallel to the fixed one. Both panels are fastened together with self-tapping screws. After this, the sheets are once again carefully aligned along the cornice and finally fixed to the sheathing using self-tapping screws with rubber gaskets. Further laying is carried out by overlapping part of the new sheet onto the already fixed one. Also, many craftsmen stack sheets from left to right, slipping the next sheet into the lock of the previous one. This way you can achieve more precise joining of sheets in locks.

Endovy

One of the important elements when installing a metal roof is the valley. It represents the internal joint of the roof surfaces in contact with each other. The base for the valley must be formed from a solid surface. For this, wide boards are used or several standard sheathing bars are combined. The instructions provide for the installation of both lower and upper ends. The lower elements are fixed directly to the surface of the sheathing using self-tapping screws. The lower valley is made of durable galvanized steel sheet. The technology of roofing equipment using a lower valley involves the drainage of water that penetrates under the roofing at the junction of the slopes. The design of this type of valley is an equilateral element with an internal angle of 135 degrees, the edges of which are curved. The upper valley for a metal tile roof has more of a decorative value in order to hide the joint of the sheets with the lower valley. As the technology for arranging a metal tile roof provides, the upper valley is installed at the last stages of the work.

The upper valley for a metal tile roof has more of a decorative value in order to hide the joint of the sheets with the lower valley. As the technology for arranging a metal tile roof provides, the upper valley is installed at the last stages of the work. End strips

Another important element of a metal roof is the end strip. This part is designed to protect the edge of the metal tile sheet from precipitation under its surface, as well as the accumulation of dust, leaves or other debris between the end board and the roof surface. In addition, the end strip protects the structure from wind loads and gives the roof an aesthetic appearance. The end strips must be fixed directly to the end board, and its edge must be in close contact with the metal tile sheet. The end strips need to be fixed in increments of 50–60 cm, and the overlap between such elements should be at least 5 cm. Based on the name of this element, it is easy to guess its purpose and location in the metal roofing structure. Installation of the eaves strip completes the arrangement of the roof frame. It should be attached after fixing the frontal (cornice) board to the frame.

Another important element of a metal roof is the end strip. This part is designed to protect the edge of the metal tile sheet from precipitation under its surface, as well as the accumulation of dust, leaves or other debris between the end board and the roof surface. In addition, the end strip protects the structure from wind loads and gives the roof an aesthetic appearance. The end strips must be fixed directly to the end board, and its edge must be in close contact with the metal tile sheet. The end strips need to be fixed in increments of 50–60 cm, and the overlap between such elements should be at least 5 cm. Based on the name of this element, it is easy to guess its purpose and location in the metal roofing structure. Installation of the eaves strip completes the arrangement of the roof frame. It should be attached after fixing the frontal (cornice) board to the frame.  The instructions for carrying out work on arranging a roof made of metal tiles stipulate the need to overlap the lower edge of the waterproofing onto the eaves strip, which will protect against water penetration into the supporting structure.

The instructions for carrying out work on arranging a roof made of metal tiles stipulate the need to overlap the lower edge of the waterproofing onto the eaves strip, which will protect against water penetration into the supporting structure. Ridge strips

Metal roofing at the upper joints of the slopes requires the presence of protective parts that provide natural ventilation of the under-roof space and hide the distance between the sheet material, providing reliable protection against water ingress. Ridge strips act as such an element. Skates can be either flat or rounded. The technology for their installation involves fastening using roofing screws with rubber seals, and it is recommended to place a ridge seal under the bar itself. This detail prevents precipitation, debris or insects from entering under the roof surface.

Snow guards and other safety elements

The roofing structure made of metal tiles requires additional accessories to ensure its safe operation and maintenance. So, to prevent uncontrolled snow falling from the roof and possible injury to people, snow retainers are installed (some manufacturers label such elements as snow catchers). The installation diagram may provide for the arrangement of these elements in one line at a certain distance, as well as in a checkerboard pattern. These elements need to be fastened after the second or third wave of metal tiles from the eaves strip. Snow guards have two most common designs - in the form of slats of various formats or interconnected tubes.

As you know, movement on the surface of a metal tile can cause its deformation. Accessories such as walkways and roof railings will ensure the safety of roofing sheets and the safety of movement on them. The installation scheme for such roofing elements should provide for the presence of a separate continuous sheathing. It is also possible to install special ladders, with which you can climb slopes with too steep a slope. The installation instructions for these elements provide for the mandatory sealing of the places of attachment to the surface of the metal tile roof. In this case, the staircase can consist of two conjugate structures - wall and roof. These accessories also include brackets, seals, supports, handrails and wall flanges.

Junction strips

An important stage in the installation of a metal tile roof is the arrangement of junctions of the sheet material with the structural elements of the building, which are located on the roof. These include roof windows, chimneys, and ventilation outlets. And if in the case of roof windows it is enough to use the parts that come with the window, then the chimney outlet must be equipped with special strips. The correct technology for equipping such units prevents precipitation from getting between the chimney and the surrounding sheets of metal tiles. As in the case of installing valleys, abutment strips can also be used in two types - external and internal. The so-called internal apron completely covers the perimeter of the chimney and is fixed with the location of the upper curved edge into a pre-equipped groove in the chimney masonry. After this, the internal connection is equipped with water drainage under the sheets of metal tiles. After laying the sheet roofing material, you need to install the external abutment strips. According to the internal principle, the edges of these strips are also placed in a pre-prepared groove in the chimney. Special accessories are installed on top of the ventilation outlets passing through the roof to prevent water or leaves from entering the channels.

Special accessories are installed on top of the ventilation outlets passing through the roof to prevent water or leaves from entering the channels.  To install the described parts, you need to make a hole in the roof and secure them with self-tapping screws, not forgetting about the sealing gasket that comes with the kit. Sewer outlets and mounting points for television antennas are installed using a similar procedure.

To install the described parts, you need to make a hole in the roof and secure them with self-tapping screws, not forgetting about the sealing gasket that comes with the kit. Sewer outlets and mounting points for television antennas are installed using a similar procedure. Metal tiles are a facing material made of thin-sheet galvanized steel. It is manufactured in the form of profiled metal sheets with a characteristic appearance, imitating the structure of natural tiles.

Profiling is carried out by giving the sheets a wavy or trapezoidal shape, which significantly increases the performance characteristics of the material. One of the leaders on the market at the moment is metal tiles and...

Before we begin installing a roof under metal tiles, let’s look at the roofs.

TO advantages of the material can be attributed:

- Light weight.

- High wear resistance.

- Fire resistance.

- Relative ease of installation.

- Good potential for implementing design solutions.

There are also minor flaws, which can be eliminated with proper planning and execution of work:

- Low sound insulation: during precipitation and strong winds, metal tiles create an increased noise level. The disadvantage is offset by the use of good sound insulation, the function of which is usually performed by a thermal insulation layer.

- Condensation may form in the interior of the roof; to avoid this, you need to take care of the arrangement and.

Installation of metal roofing: technology and design choice

Roofing pie is a structure made of materials that fill the roof space layer by layer.

The construction of a metal roof depends on the type of roof, which can be warm or cold. Cold roof- this is a roof without laying insulating layers, it is appropriate in cases where the house has an attic, and insulation can be laid in its ceiling. Warm roof necessary when the living space is located directly under the roof.

Cold roof design

A cold roof under metal tiles has only two main layers: metal roofing and to prevent condensation.

The covering and waterproofing are separated from each other by lathing and counter lathing. Ventilation is provided at the roof ridge (the point where the slopes meet); this is necessary to allow air to enter the interior space and to ensure the evaporation of accumulated water.

The waterproofing layer is made of PVC membranes or polyethylene films. When laying it full tension is unacceptable film, you should leave it sagging by 20-25 millimeters - this will improve its conductivity and facilitate the drainage of moisture.

The waterproofing is attached to the rafters with a construction stapler and fixed under the sheathing using self-tapping screws.

Thus, the cold roof structure will consist of next layers(in order of distance from the ceiling):

- Waterproofing.

- Counter-lattice.

- Lathing.

- Metal tiles.

Cold roof device

The warm roof pie contains more layers.

Attic roof installation

The main structure here is the insulation; it fills most of the space between the rafters and performs soundproofing functions. Its thickness depends on the climatic characteristics of the region and on the characteristics of the building, most often it is 15 cm or more. Fire resistance is one of the most important characteristics of insulation.

Thermal insulation is laid in the spaces of the grids formed by the rafters.

The most common materials for insulation include:

- extruded polystyrene foam;

- Styrofoam;

- glass wool;

- basalt;

- expanded clay

Another necessary element of the warm roof “pie” is the vapor barrier layer. He protects insulation from condensation penetrating from the side of the room.

The vapor barrier is attached to the rafters using a stapler. She must be below the thermal insulation layer.

The vapor barrier is attached to the rafters using a stapler. She must be below the thermal insulation layer.

Vapor barrier films are made on the basis of polyethylene, polypropylene, and isospan.

Waterproofing is a necessary design not only in cold roofs, but also in warm ones. The principles of its selection and installation are the same for both varieties.

Final roof structure made of metal tiles will have the following ordered layers:

- Bottom sheathing (isolates the vapor barrier from the thermal insulation).

- Counter-lattice.

- Lathing.

- Metal tiles.

The middle position of the insulation between the outer and inner protective layers provides it with maximum safety and wear resistance.

Metal roofing: technology for creating an insulated roof

Between all layers should be left small gaps to create natural ventilation.

Dense filling of the space between the rafters is the key to the reliability and durability of the roof. Insufficient layer thickness cake will lead to the formation of large empty spaces, accumulating moisture and reducing the performance properties of the coating.

The other extreme should also be avoided - too thick layers, since in this case the ventilation will be blocked.

Installation of metal roofing over wooden sheathing

The main purpose of the lathing is roof frame support formed by the rafters. Waterproofing and metal tiles are attached to it, it creates a natural  ventilation internal roof space.

ventilation internal roof space.

There are two types of lathing - solid and sparse. In a solid structure, all the boards are adjacent to each other, which provides increased strength of the frame, but significantly increases the cost of material.

In sparse lathing, the boards are located at a certain distance from each other.

- Average optimal value The tilt angle is 22 degrees, the minimum is 14 degrees. A lower value does not provide sufficient structural strength and does not make it possible to use the attic space.

- High angle tilt increases the volume of attic space, but it has a drawback - the windage of the structure increases, that is, its exposure to wind.

- The optimal value of the indicator can be calculated independently. To do this, you need to find one-half of the width of the gable, divide this number by the desired roof height and calculate the sine of the division result.

Rafter system constructed from metal or wooden beams. This main roof frame, the operational potential of the entire structure will depend on the reliability of its device. To create a roof made of metal tiles, wooden beams are usually used.

Installation of rafter beams

It is a system of supports that are fastened to each other in various ways depending on the roof structure, the number of slopes and their angles. The lathing is attached to this system, which is an additional, secondary frame.

Fastening metal tiles to the structure

Sheets of metal profiles are attached to the sheathing. For this purpose they are used roofing screws, which are screwed into the cavity of the tile wave using an electric drill.

As a rule, fastening begins. When performing work, you should move along the profile with great care, as the material is easily pressed.

After completing the fastening of the tiles, you can begin installation additional elements.

These are the main stages of installing metal tile roofs.

Working with this material is relatively simple; the main difficulties are associated with ensuring good ventilation and protecting the roof from moisture and wind.

Useful video

Installation of metal tiles using a practical example:

Metal tiles are one of the most popular roofing materials among owners of country houses. In addition to excellent performance characteristics, it has another important advantage - ease of installation. You can cover the roof with roofing sheets of this type yourself.

What tools and materials will you need?

- Screwdriver and hammer;

- Electric hacksaws and scissors;

- Long staff and marker.

An electric hacksaw is needed for cutting rafters and boards. Using metal scissors, metal tiles are cut.

You cannot cut this material with a grinder. Otherwise, due to damage to the top layer by sparks, the sheets will not last long and you will have to repair the roof with reinstallation of the roofing material.

From the materials you will need to prepare:

- Beam for rafters 50x150 mm;

- Beam for Mauerlat 150x150 mm;

- Lathing board 25x100 mm;

- 30x50 mm batten for counter-lattice;

- Waterproofing membrane;

- Mineral wool;

- Consumables.

The cross-section of lumber must be maintained. Otherwise, the owners of the house will soon have to repair the roof or even reinstall it after assembly.

In addition to the metal tiles themselves, you will need to purchase various types of additional elements: cornice and end strips, valleys, ridge element, chimney apron, snow retainers, etc.

Additional elements for metal tiles

Additional elements for metal tiles How much does a metal roofing cost?

The cost of a roof made of this material depends on several factors:

- Type of polymer coating material;

- Difficulty in roof configuration;

- Type of insulation used;

- Roof size.

On average, 1 m2 of metal roofing costs approximately 1,000 rubles. Therefore, making a preliminary rough calculation will not be difficult. To do this, the roof area in square meters should simply be multiplied by 1000.

Features of constructing a roof made of metal tiles

Of course, the installation of this material on the installed frame should be carried out correctly. This applies to both the assembly of the rafter system and the cutting and installation of the sheets themselves. There will be no need to repair the roof for a long time even if it is properly covered with waterproofing.

Preparatory work

The construction of a rafter system begins with measuring all the walls and eliminating discrepancies in their dimensions. The smoother the structural elements of the house frame are, the less effort will subsequently have to be spent on adjusting the rafter legs. Before starting work on assembling the roof, all lumber must be dried under a canopy for several months. The Mauerlat is installed first, and then the beams for the floor.

Material measurements

In order to draw up a roof plan, various types of measurements should be taken. For example, all the videos available on this topic on the Internet present this process like this:

- First of all, measure the exact length of all the walls of the box. Based on this, the area of the slopes is determined;

- Determine where the chimney, ventilation holes, roof windows, etc. will be located.

In accordance with the results obtained, the sheets and timber are then calculated.

Lumber calculation

After the roof project has been drawn up, you can begin to calculate the required lumber. Their number depends primarily on the angle of inclination of the slopes and the area of the roof. Most often, a gable roof with a slope of 30–35 degrees is installed under metal tiles.

The amount of timber for the rafter legs is determined depending on the step at which they are going to be installed, the height of the roof and its dimensions.

The length of one leg is calculated by the formula c = √(v2 + m2), where v is the height of the roof, and m is half the span length.

The pitch between the rafters on a roof with a metal tile roof is usually 80–100 cm (depending on the width of the sheets). You can calculate the required number of rafters as follows:

- Divide the length of the wall by the selected step;

- Add one to the result and round up.

The rafter system for metal tiles does not require any additional reinforcement. The amount of material required for the sheathing is calculated based on the fact that the pitch between its elements should be 35–40 cm.

Assembling the rafter system

The roof frame is constructed using the following technology:

- Mauerlat is fixed on the walls. It can be fixed with studs embedded in the masonry, or with anchor bolts cast into the upper reinforcing belt;

- Mount the rafters. The easiest way is to fix the legs on the support beam using corners (preferably galvanized ones, otherwise you will soon have to carry out roof repairs and replace them). The top of the rafters is most often cut at an appropriate angle and fastened in pairs using steel strips and crossbars.

Roof frame construction

Roof frame construction On large and high roofs, ridge beams are often used. In this case, the rafters are secured with planks above it and additionally pulled to it with corners. The ridge beam itself is mounted on racks fixed to the Mauerlat of the short walls of the house box.

Hydro- and thermal insulation device

Sometimes a cold roof is made from metal tiles. However, most often it is still insulated, as this significantly improves its performance characteristics. Wire or sparse plank sheathing is used as support for the heat insulator from the attic side. They insert cotton wool between the rafters at random. The top should be covered with waterproofing material, securing it with bars.

Waterproofing scheme

Waterproofing scheme The strips are placed horizontally with an overlap of 15 cm. Do not stretch the film too tightly. Otherwise, when the rafter system moves due to shrinkage of the walls and wind, it may break. The sag of the film should be about 2 cm.

Roof sheathing

It is correct to assemble the base for metal tiles from fairly wide boards (at least 20 cm). Narrow material may warp under the influence of adverse weather factors. The sheathing is installed using a pole and a building level.

The distance between the first two sheathing boards from the bottom should be very small - 10–15 cm. The sheathing is arranged with the elements fastened to two nails to each rafter. In this way, you can assemble a reliable base for metal tile sheets.

How to correctly calculate metal tiles

After assembling the sheathing, you can install the roofing sheets themselves. But of course, you must first make an accurate calculation of the required quantity. A video demonstrating the process of performing these operations is available on the Internet. You can, of course, look at it, but in principle there is nothing complicated in such a calculation. Perform this operation like this:

- Calculate the area of each slope;

- Calculate the number of sheets required to cover it, taking into account their width and length;

- Add up the results obtained.

How to properly install cornice strips and lower valleys

The instructions for attaching these elements are simple. The cornice strip is installed before the sheets are installed. The frontal board is pre-stuffed. The gutter brackets are attached to it. Next, you can begin to actually attach the bar itself.

Installation of cornice strips

Installation of cornice strips Another element that needs to be installed before covering the slopes with metal tiles is the lower protective valleys. Their installation is carried out in compliance with the following recommendations:

- The sheathing under the valley must be continuous;

- Installation of valley elements begins from the bottom up;

- Each lower element should be overlapped with the upper one by at least 10 cm.

Choosing metal tiles

There are several types of metal tiles. When choosing this material, you should consider the following:

- Only sheets made of steel with a thickness of at least 0.45 mm are considered reliable;

- In central Russia, roofs are usually covered with inexpensive sheets with a polyester protective layer;

- The warranty period for good material is at least 10–15 years. Home owners who buy this material will not have to pay for repairs if any problems arise.

Installation of sheets

So, now let's see how to cover a roof with metal tiles with your own hands. Installation of sheets begins from the bottom. When assembling the first row, a cornice overhang about 5 cm wide is arranged. Actually, the instructions for filing themselves look like this:

- The first sheet is attached with one screw at the very top;

- Then several more sheets (2–3) are attached to it along the side edge;

- The entire pack is carefully leveled and secured to the roof frame.

Installation of additional elements

After all the slopes are sheathed, you can begin installing additional elements. First, the upper valley strips are attached. In this case, they perform mainly a purely decorative function. They are mounted on a self-expanding seal.

At the next stage, the end elements are fixed to the gables. Next, the ridge is installed. They fasten it in the same way as the upper valleys on the sealing tape.

Attic roof roof

The installation of the rafter system of the attic roof is carried out as follows:

- Racks are attached under the layered rafters, purlins and tie-downs;

- The ridge is being installed. Its racks are secured in the middle of the puffs;

- Layered and then hanging rafters are installed;

- The sheathing is filled taking into account the characteristics of the roofing material.

Metal tiles are first sheathed on the sheathing of the layered rafters, and then on the hanging rafters. On the latter, in the same way as on the cornice, an overhang is made.

Some subtleties of installing metal tiles

The installation of sheets should be carried out by at least two people in compliance with the following recommendations:

- The capillary grooves must be completely covered by the next sheets in the row;

- All sheets must be carefully aligned parallel to the cornice.

We cover the roof: how to get around the chimney

Scheme of bypassing a pipe with metal tiles

Scheme of bypassing a pipe with metal tiles The construction of a metal tile roof must be such that in the area where the material adjoins the chimney pipe, water does not leak into the under-roof space. To solve this problem, special aprons are used. The instructions for installing them are as follows:

- Before laying the metal tiles, a continuous sheathing is packed around the pipe. A waterproofing material is glued onto it with an overlap of 15–20 cm over the pipe walls. A groove is made in the chimney itself around the entire perimeter.

- After laying the metal tiles, the lower apron is installed first, and then the upper one. The bent edges of their vertical parts are inserted into the groove.

Subtleties of installing curtain rods

The cornice and end strips must be fixed to the wood of the frame in increments of approximately 30 cm. If this condition is not met, they may subsequently move away, and unnecessary repairs will have to be made. It is highly not recommended to mount them end-to-end. Each subsequent plank must overlap the previous one by at least 1 cm. These elements are fastened with galvanized nails or self-tapping screws in a checkerboard pattern.

Installation of valleys: features

The lower valley should be secured with self-tapping screws into each purlin. Its overlap on the slopes should be at least 25 cm. In this case, there will be no need to repair the roof due to a rotten frame. The upper valley is mounted in such a way as not to damage the lower one. They attach it to the metal tiles either with special corners or with self-tapping screws at the top of the wave (in each).

Fastening sheets to roof breaks

Installation of roof breaks

Installation of roof breaks As already mentioned, on attic sloping roofs, metal tiles are laid on the break with an overhang. Before installation, a drip strip (in increments of 30 cm) is usually mounted on the edges of the slopes of such a rafter system for reliability.

Sometimes there is another type of fracture in the roof configuration - with a negative angle. They close it in much the same way as valleys. In this case, the carpet is laid in such a width that it extends at least 35 cm onto the upper part of the slope, and 15 cm onto the lower part. The sheathing under it should also be continuous.

Installation of snow guards

This additional element is mounted on flat roofs to avoid snow avalanches. The instructions for installing snow guards include the following steps:

- Fastening is done with long self-tapping screws into the sheathing;

- You need to make holes in the metal tiles and line them with rubber seals;

- The brackets must be screwed correctly at a distance of at least 35 cm from the cornice.

Installation of lightning protection

Lightning protection scheme for a metal roof

Lightning protection scheme for a metal roof This system must be assembled. If the lightning is attracted by the metal covering, you will have to carry out expensive roof repairs. And of course, natural electrical discharge is a very dangerous phenomenon for those living in the house. Lightning protection is assembled from the following elements:

- Lightning rod, which is a rod with a length of 5 m;

- Down conductor (circular wire);

- Grounding conductor made of a metal strip with a thickness of at least 150 mm.

The lightning rod is fixed to the roof ridge. A wire is wrapped around the chimney and connected to the middle of the rod. The ground electrode is dug into the ground to a depth of at least 80 cm and connected to the lightning rod via a down conductor.

Safety precautions

When installing metal tile sheets, observe the following safety rules:

- Cutting sheets and installing them on the roof is done using gloves;

- Take the sheets by the edges from the sides;

- To move along long slopes, special stairs are used;

- People walk on the roof in soft shoes. In this case, there will be no need for early repairs due to damage to the coating.

Conclusion

As you can see, installing metal tiles is a relatively simple matter. Numerous videos and photos available on the Internet confirm this. The rafter system for this material may not be too powerful, since its weight is not particularly large. In this case, the rafters and sheathing are mounted using standard methods. When installing the sheets themselves, you should adhere to all the required technologies: do not cut the material with a grinder and correctly fasten all additional elements. In this case, the roof will be reliable and its repair will not be required for as long as possible.

Detailed instructions for installing metal roofing are presented in the video.