Sandwich chimneys have many advantages: lightness of construction, safety, aesthetic appearance. Why not try to assemble a sandwich chimney with your own hands? As practice shows, it is really quite simple. And everyone can build such a chimney like a construction set.

This work will require knowledge of the structure of the chimney and its installation - we discussed this material in detail in our article. We selected photos and diagrams describing the main elements of the chimney system, and provided step-by-step instructions for assembly and installation.

We also supplemented the material with useful tips for improving draft and a video demonstrating the process of installing a chimney in a country house.

Disadvantages of chimneys assembled from sandwich pipes:

- failure of sealing after a certain number of heating and cooling cycles;

- compared to a brick structure, a sandwich chimney has a higher cost;

- The service life is about 15 years, while traditional fire brick chimneys last 10 years longer.

This short service life is mainly due to the use of low-quality materials in production.

Choosing products from a trusted brand is the first thing you can do for the long and successful operation of your chimney.

Image gallery

How to prevent problems with traction?

- the height of the structure must be equal to or greater than five meters;

- it is preferable to build a straight chimney - without bends and turns;

- turns (no more than three) are made at an angle of 45°;

- An almost horizontal section of the chimney can extend from the boiler (with a slope of 2°), but not more than one meter.

If during the operation of the chimney problems are discovered with smoke removal, they resort to installing special devices that increase draft.

It could be:

- It works on the principle of reducing pressure as air passes around obstacles. It works effectively in windy weather, but in calm weather it can, on the contrary, hinder the removal of smoke.

- Stabilizer. It is an additional element that has the shape of an umbrella and is placed on top of the pipe. From below, air enters through the open area, increasing traction.

- Rotary turbine. It works using the force of the wind: rotating in one direction, it creates a vacuum of air above the channel. It is not effective in calm weather.

All these devices are not a panacea, especially if the chimney is not initially designed correctly.

The deflector may interfere with the removal of combustion products in calm weather

Operation of chimney sandwich systems

After installing the chimney, you should conduct a test fire to check the tightness of the joints and make sure that the adjacent structures and materials do not heat up.

When using the system for the first time, light smoke and a specific smell may appear from the heating of oil residues, sealant, and dust on the surface of the pipes.

Correct operation requires timely. When cleaning, do not use any detergents. A review of the best cleaning products and methods is discussed in.

It is better if it is carried out by an organization that has a special license giving the right to carry out this type of work.

Conclusions and useful video on the topic

More information on how to correctly assemble a reliable chimney from modular sandwich pipes can be viewed in the video:

Independent installation of a chimney from sandwich pipes will require the user to study some of the nuances and subtleties. But by doing the job correctly, you can be confident in the safety of your family and yourself.

Do you have experience assembling a chimney from sandwich labor? Did you install such a chimney yourself? Share your experience with novice home craftsmen - write in the comments block what difficulties you encountered during installation, how long you have been using it and how you care for your chimney.

It is well known that for the operation of any type of heat source, with the possible exception of an electric boiler, a system for removing fuel combustion products is required. You can arrange a chimney in the form of a traditional brick pipe; it is also possible to use modern composite materials to solve this problem.

Currently, metal sandwich chimneys are widely used among professional builders and owners of private houses. They are distinguished by excellent performance and long service life. Installing a sandwich chimney with your own hands does not present any significant difficulties and can be completed much faster than building a conventional brick chimney if the correct assembly technology is followed.

A chimney made from sandwich pipes can be elegantAdvantages and disadvantages of a chimney made from a sandwich pipe

The use of metal pipes to remove fuel combustion products has been practiced since ancient times. This is due to the fact that their shape is optimal for the flow of hot gases; less soot buildup forms on the smooth inner surface. In addition, compared to brickwork, installation work is significantly simplified.

Chimneys made of metal pipes are exposed to aggressive hot gases. This leads to the development of corrosion processes and, ultimately, to burnout of the exhaust system. The use of corrosion-resistant metal alloys for its manufacture solves the problem only partially, while the following negative factors remain:

- Reduced draft in the chimney due to the high thermal conductivity of the metal. This is due to the rapid cooling of hot gases in the external parts of the structure in contact with the environment.

- Condensation of moisture vapor on the internal surfaces of pipes due to temperature differences. This leads to a decrease in their permeability and contributes to the formation of soot deposits.

- A hot metal chimney poses a fire hazard. Elements of a building structure may catch fire, touching the surface of which results in a burn for a person.

The design of sandwich chimneys, which consists of coaxially located pipes separated by a heat-insulating gasket, allows you to get rid of such unpleasant phenomena. The inner pipe is made of a metal alloy that is resistant to corrosion, and the outer pipe is often made too. Thermal insulation gasket is most often made of dense mineral wool. Sandwich pipes for installing a chimney allow you to protect the smoke removal channel from temperature fluctuations in the external environment. Sandwich chimney pipes have the following advantages:

- minimal condensation formation;

- good traction;

- fire safety;

- possibility of installation outside the building;

- long service life.

You can make a sandwich pipe yourself

You can make a sandwich pipe yourself The disadvantages of sandwich chimney elements include possible depressurization of the structure during long-term operation. If there are sharp temperature fluctuations in the external environment, the mechanical integrity of the product may be compromised. In addition, they have a fairly high cost. Of course, a sandwich pipe installed by yourself reduces material costs.

The quality of pipe materials is critical

The performance and service life of a sandwich chimney largely depends on the quality of the material from which its pipes are made. Popularity among consumers gives rise to a large number of counterfeit products, so you should pay special attention to the properties of the metal from which sandwich pipes are made.

If it burns out, there is a high probability of a fire and carbon monoxide poisoning of residents.

It is not possible to visually determine the quality of the metal, so you need to understand its grades. Stainless steel grades have the following characteristics:

- The cheapest steel is AISI 430. It can be used for the manufacture of an external pipe; atmospheric influences will not cause harm, but for the construction of an internal chimney duct the durability of this material is clearly not enough.

- In the AISI 439 metal grade, corrosion resistance and mechanical strength are increased by the titanium additives included in its composition. This steel can be used to remove combustion products in gas furnaces and small boilers.

- High resistance to aggressive chemical environments and high temperatures is ensured by the addition of molybdenum and nickel to AISI 316 steel. Its use is possible in smoke removal systems of any boiler equipment.

- Stainless steel grades AISI 316i and AISI 321 are distinguished by their universal performance characteristics. They can withstand heating to very high temperatures and have high corrosion resistance.

- AISI 310S stainless steel has the highest price and performance characteristics. It can withstand heating up to a thousand degrees Celsius, therefore it is used in any thermal energy generators.

The result of using low-quality pipes

The result of using low-quality pipes In the technical documentation of quality products, the grade of steel from which they are made must be indicated. You should be wary if this information is missing, in which case it is easy to run into counterfeit products.

Note that the magnet is not attracted to stainless steel with alloying additives, so you can check the metal in this simple way.

The influence of fuel type on the choice of chimney

The choice of chimney is greatly influenced by the type of fuel burned in the thermal energy generator. The chemical composition of combustion products is very important. When burning natural gas, water, carbon dioxide and some soot are formed, and when burning wood, coal or liquid fuel, many chemically aggressive components are formed.

In any case, the internal surface of the chimney must have low adhesion and chemical inertness to the effects of acidic components. Solid or liquid fuels place increased demands on the quality of the materials from which chimney pipes are made.

The temperature of the generated smoke is of great practical importance. The exhaust of gas-fueled boilers can be connected to the smoke duct through a corrugated aluminum hose, but it is no longer suitable for solid fuel. This will require the use of materials more resistant to high temperatures, especially near the exit of combustion products.

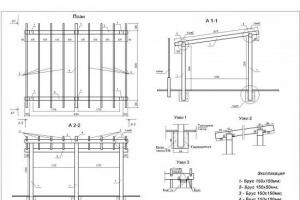

List of structural elements of sandwich chimneys

A sandwich chimney is a structure assembled from individual segments. Sandwich chimney segments: inside a pipe of a larger diameter a pipe of a smaller cross-section is placed, between them there is a dense thermal insulating material, most often basalt wool. It is not afraid of chemical and physical influences and easily tolerates significant temperature changes.

The materials used to make pipes are stainless steel, copper, brass or aluminum. Copper and brass pipes are expensive. Aluminum is much cheaper, but it greatly changes its geometric dimensions when heated and cooled, so the seal of a chimney made from it may be compromised.

List of elements of a chimney made of sandwich pipes

List of elements of a chimney made of sandwich pipes Setting up a smoke removal system requires the use of many elements for its installation. The main parts of the exhaust duct for removing combustion products are:

- straight pipe sections;

- tees and knee joints;

- pipes for passages through interfloor ceilings;

- seal for a pipe passing through the roof.

Along with these elements, there are many other installation devices that make it easier to carry out the work and further operate the exhaust system. The chimney pipes are secured to the building elements using brackets, which are placed every two meters of the gas exhaust channel. The clamps used for installation are fixed on the wall with fasteners corresponding to the building material from which the wall is made.

You need to assemble sandwich chimneys with your own hands, following the connection diagram of the structural parts. For reliable operation of the system, the installation of sandwich chimney pipes must be done carefully and carefully.

Selecting the pipe diameter for specific conditions

The diameter of the double-circuit pipe must correspond to the outlet pipe of the boiler equipment; the internal casing of the sandwich should in no case be smaller in size. The lumen of the pipeline should not be allowed to narrow at the junction; this may reduce the draft of the chimney. The pipe diameter required for specific conditions is selected depending on the power of the boiler equipment.

Sandwich pipe device

Sandwich pipe device A pipe cross-section of eight centimeters is used for installations with a power of less than three and a half kilowatts. Pipes with a diameter of nine and a half centimeters are used for boilers with a power of no more than 5.2 kilowatts; for larger values of this parameter, pipes with a cross-section of eleven centimeters will be required. During the installation of the chimney, it should not be allowed to narrow, but it is quite possible to expand it.

DIY sandwich pipe installation

To properly install sandwich pipes, you must follow the following recommendations. Before installing a sandwich chimney with your own hands, you need to calculate the required quantity of all elements, taking into account the design features of the house. You should carefully study the technical documentation for the product and familiarize yourself with the safety recommendations when installing a chimney pipe through a wall or ceiling.

Everything necessary should be done to prevent the possibility of fire in nearby parts of the building structure during operation of the chimney. When installing a chimney through a wall, sandwich pipes are reliably strengthened.

Arrangement of a sandwich chimney inside a building

Arrangement of a sandwich chimney inside a building There are two placement options: internal installation with wiring through the attic floor and installation of a sandwich pipe with exit through the wall and fastening to it from the outside. When installed internally, the pipeline does not experience the negative influence of the external environment, and the formation of condensate on the internal surface is minimized. To complete the work you will need the following tools:

- perforator for making holes in ceilings;

- electric drill for attaching brackets;

- slotted and Phillips screwdrivers;

- building level and stairs.

Assembly of system elements

The assembly of chimney system elements always starts from the bottom and then moves to the top. The sandwich chimney cannot be connected directly to the source of thermal energy. First, an adapter coated with a sealant resistant to high temperatures is put on the outlet pipe of the furnace or boiler, then the main pipe is installed. The connection point is securely fixed with a metal clamp.

Sandwich pipe installation options

Sandwich pipe installation options There are two ways to install sandwich pipes: “by smoke” or “by condensate”. In the first case, each previous pipe is inserted inside the next one. This is how both the internal and external parts are assembled. This chimney connection option is used for stoves with high fuel combustion temperatures.

For condensate, the pipes are connected as follows: the inner pipe is assembled by sequentially inserting the upper section into the lower one, the outer pipe is assembled in the opposite way, that is, by inserting the previous element into the next one. With this installation of the chimney, the resulting condensate flows down the outer casing into the drainage, and therefore it is used in the following cases:

- at low temperatures of combustion products;

- if the chimney is located outside the building;

- in long-term or smoldering combustion systems.

In a situation where the chimney goes vertically upward, as in a sauna stove, a pipe with one wall is installed at its outlet and a sandwich pipe is connected to it. If the latter is connected directly to the furnace, the layer of insulating material between the walls of the two pipes will sinter and cease to perform its functions. In the case when it is necessary to obtain more heat from the chimney, the length of the single pipe increases, and a tank for heating water can be placed on it. At the same time, the nearby walls of the room are protected from exposure to high temperatures by a screen.

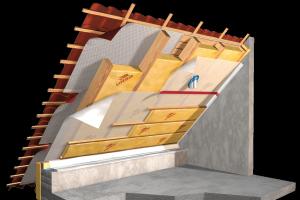

How to properly route a sandwich pipe through the ceiling and wall

It is possible to remove and secure the pipes using a box with a hole made inside it. The height of the box should be approximately seven centimeters greater than the thickness of the ceiling to prevent it from catching fire. It must be taken into account that, despite the presence of a thermal insulation gasket, the outer surface of the chimney can warm up to fairly high temperatures. As a result, it is necessary to carry out additional insulation in places of contact with flammable materials, such as wood, plastic, and so on.

Options for arranging a chimney outlet through the ceiling

Options for arranging a chimney outlet through the ceiling Inside the box there is a special piece of pipe that should not have joints, and this is an important requirement when performing installation. You must first make precise markings with a marker. After installing a piece of pipe in the box, the joints must be carefully insulated.

The size of the hole cut for the passage of the pipe must exceed its cross-section by at least two hundred and fifty millimeters. A heat-resistant material is placed in the resulting gap, most often basalt wool. In addition to providing thermal insulation, this prevents damage to the chimney due to shrinkage of building structure elements or their deformation under the influence of temperature or humidity.

Installation of a sandwich chimney through a wall

Installation of a sandwich chimney through a wall To lay a chimney through ceilings made of materials susceptible to combustion, special units with an air gap between the outer part and the inner surface are used. In the case when the material is not flammable, instead of the passage element it is possible to install an unloading platform, which will serve as an additional support for the structure.

How to make a chimney system pass through the roof

To exit the chimney system through the roof, the opening must be properly equipped. On the attic side, around the pipe you need to fasten a sheet of metal or a specially prepared panel with a hole. The structure is strengthened with bars or lathing.

The chimney, when passing through the roof, breaks its tightness. To prevent leaks, an insulating material called roof penetration is used. The latter is a pyramid, which consists of several steps placed on a flexible round or square flange. The material of such a product is silicone or weather-resistant types of rubber.

Installation of sandwich pipes through the roof

Installation of sandwich pipes through the roof Thanks to the elasticity of these materials, the penetration is reliably compatible with any type of roof and resists the aggressive influence of the external environment. This part is selected depending on the diameter of the pipe and the angle of the roof. A penetration made of metal has excellent performance properties, but its installation is only possible on a roof without a relief pattern or a soft roof. At the same time, for high-quality sealing, it is necessary to accurately match the location of the flange to the slope of the coating.

Attaching the chimney to the wall

When placed outdoors, every two meters of the assembly the chimney is mounted to the wall with reliable brackets. If the installation diagram includes tees or bends, then each such element is also mounted to the wall. This makes it possible to maintain the chimney in a vertical position, reduce the load on the butt joints and make it impossible for destruction as a result of heavy gusts of wind.

Installing a sandwich chimney outside the building

Installing a sandwich chimney outside the building Butt joints are tightened with metal clamps. Bends and tees are fixed using individual brackets. A gap is necessarily left between the wall and the chimney, which is called a setback; its size depends on the degree of flammability of the finishing materials, the thickness of the partition of the boiler equipment, and so on.

Options for mounting the chimney on the wall

Options for mounting the chimney on the wall It is recommended to purchase fasteners with a margin of about thirty percent, since in this case you will not have to be distracted from work if parts are damaged. You must strictly follow the instructions for assembling the product and use only high quality fasteners. The brackets must match the building material from which the wall is made.

How to install a chimney on the roof

When installing a chimney on the roof, it is necessary to take into account its appearance and the location of buildings in the neighborhood. The pipe should not be located in an area where natural draft will deteriorate. The height of the location above the roof is determined by the distance between the pipe and the ridge, above which it should rise no less than fifty centimeters. Above a flat roof, the elevation should be at least one hundred and twenty centimeters, if the roof is combined - at least two hundred centimeters.

In the case where the ridge is located from the pipe at a distance of one and a half to three meters, the chimney can be located on a common level with it. At a greater distance from the ridge, a horizontal line is drawn with a decline angle of ten degrees, and the chimney is placed no lower than this line. If these rules are not followed, reverse draft may form in the system for removing fuel combustion products.

Roof pipe installation height

Roof pipe installation height A spark catcher is installed in the chimney pipe if flammable materials were used in the manufacture of the roof. A cone-shaped head is mounted above the outlet hole. To protect against atmospheric influences, fungi or deflectors are used.

Operating the system and solving problems of poor traction

To do this, a door is provided at the bottom of the structure or a special glass is installed, which provides access to the internal parts of the sandwich pipe. Following these simple rules will help reduce the formation of soot deposits or even prevent its occurrence.

In your private home or bathhouse, if you have a heating boiler, fireplace or stove, it is very important to correctly choose the method of getting rid of combustion products. And the main one is smoke. If you approach the issue inattentively, you can not only reduce the efficiency during functional operation, but also put your own life in danger. Carbon monoxide, if it spreads indoors even in small quantities, can cause serious poisoning of the body. Correct installation and installation of a chimney pipe with your own hands is a task today accessible not only to professionals, but also to amateurs who have studied the technical side of the issue in detail.

Arrangement rules

Carbon monoxide is almost impossible to detect; it has no taste or smell, and is invisible visually. Moreover, it is heavier than air, so it settles and remains in the room. In this regard, it is necessary to follow the basic rules when installing the heat generator and chimney:

- When installing a stove or fireplace with a large mass, prepare a foundation for it in advance: a small platform that will not budge if the base of the building sag.

- Wall and ceiling ceilings, if they are made of flammable materials, should be located at a considerable distance from the flame source (about 40 cm). When passing through wall and ceiling ceilings: 500 mm - to combustible, 380 mm - to non-combustible.

- Maintain a minimum number of bends in the smoke duct. At the same time, do not allow right angles in the system; it is better to split such a bend into two sections or use elements with a smaller and larger angle.

There are standards put forward during installation work depending on the type of fuel used. These are SNiP 41-01-2003, NPB 252-98 and VDPO. Ignoring them can cause many violations that affect the quality of the heat generator. Incorrect selection of the device can lead to overheating of the floors, insufficient draft leads to soot settling, and a leaky assembly leads to smoke in the room.

Main technical characteristics of the chimney

Diameter

As a rule, manufacturers of heat-generating devices prescribe the recommended chimney diameter in their instructions. This parameter directly depends on the traction force. And it is already determined by height, the dependence is directly proportional. The main requirement: the diameter cannot be narrower than the diameter of the furnace pipe; this is prohibited.

Height

Calculation of the height of the chimney relative to the ridge is based on the requirements of SNiP 41-01-2003 and SP (building rules) 7.13130.2009, as well as on the recommendations of the heating device manufacturer.

If the roof has a flat structure, then the height above the roof is at least 50 cm. On pitched roofs, if the chimney is located at a distance from the ridge of up to 1.5 m, its height must be at least 50 cm relative to the last or enclosing parapet. If it is located within 1.5–3 meters, the height cannot be lower than the ridge or parapet. When the structure is located more than 3 meters from the ridge line, its minimum height is determined by drawing a line at an angle of 10 degrees relative to the horizon.

Material

Today, consumers have many options when choosing a smoke exhaust system:

- classic version of pipes made of brick;

- ceramic analogues;

- modular chimneys made of stainless steel, which have become popular relatively recently, but have already established themselves as a simple and at the same time reliable device.

How to install a chimney correctly - choose the type of outlet

There are two options for the passage of the chimney:

- Through the wall. The advantages of this solution are improved fire safety, minimization of smoke, the ability to simply increase draft depending on the height of the pipe, as well as installation in a finished building. But there are also disadvantages: more complex and expensive installation.

- Through the roof. The advantages of this solution are high structural stability and the absence of overcooling of flue gases. But at the same time, the probability of “missing” the occurrence of a fire is higher, since smoke occurs in the ceilings that are located in the attic and on the roof, and they are simply not visible until the fire appears.

Installation

It is imperative to adhere to the requirements of SPiP 41-01-2003 “Heating, ventilation and air conditioning”:

- The cross-sectional area of the smoke duct must be no less than the cross-sectional area of the boiler pipe. Smoke channels should be installed vertically, without ledges.

- An inlet vacuum of at least 5 Pa must be ensured. The recommended duct height is at least 5 m from the boiler air intake.

- It is mandatory to use polyurethane foam when crossing a roof or wall.

- Lack of horizontal channels for cleaning in the attic.

- Connections of parts cannot be installed in interfloor and attic floors.

- The smoke duct should not come into contact with any communications.

- Heating of nearby building elements should not exceed 50 degrees.

How to mount:

- It is not recommended to use a sandwich pipe as the first element installed directly on the outlet pipe of the heat-generating apparatus. The first item should be the adapter.

- Installation proceeds from the bottom up, each subsequent element is included in the previous one.

How to assemble a sandwich: using smoke or condensation

An important point is the choice of method for assembling the chimney. The question is especially relevant when it comes to the installation of industrial chimneys.

So, there are two basic types - condensate or smoke assembly. We definitely recommend condensate assembly: each subsequent pipe is inserted inside the previous one. Do not forget that the installation of the chimney goes from the bottom up to the heat generator.

When collecting by condensate, moisture flows down the inner wall and does not settle on the pipe, accumulating soot and corroding the walls. Another important point when assembling by condensation is that moisture does not enter the thermal insulation layer of the sandwich chimney, thereby not destroying it. This increases the service life of stainless steel pipes.

Basic requirements for the smoke channel

The main criteria are prescribed in fire safety standards. As mentioned above, the correct installation of the chimney (chimney) pipe is influenced by the diameter, height and type of assembly. A prerequisite is maintaining the distance from the walls and ceilings, the presence of a ceiling passage unit, and proper insulation of all joints.

Installation instructions for specific types

Ceramic chimneys are characterized by high resistance to high temperatures, durability and excellent performance. The smooth surface reduces the chance of soot or ash accumulation.

Divided by material:

- They are found from high-quality types of clay (this in itself is a very expensive material), the main feature of which is fine dispersion and uniformity.

- In the production of fireclay, inexpensive types of clay that have coarse particles are used.

The service life of these models also varies.

According to the type of assembly, ceramic chimneys are:

- ceramic-expanded clay - the pipe is “edged” with expanded clay blocks and looks like a brick one;

- ceramic-stainless - the shell is made of mirror stainless steel 0.8 mm thick (external effect - the pipe seems to be metal);

- expanded clay-stainless steel.

Assembling a ceramic chimney

A prefabricated structure consists of several elements:

- Inner layer. The base is made of ceramic. It is thanks to it that no harmful substances or residues accumulate inside.

- Intermediate layer. Its main purpose is heat insulation. Naturally, it is made from various non-flammable materials (mineral wool).

- External covering. Typically made from expanded clay blocks or a stainless steel casing.

Assembly order

So, in order to understand how to properly install a chimney pipe, you need to keep in mind that a ceramic chimney has several key features.

First, you need to build a foundation. A flat surface without the slightest shifts or roughness is required.

Secondly, we connect the tee using a special module. It has a pipe, and all joints are covered with a solution when connecting.

The part protruding above the roof can be covered with bricks or blocks to create a pleasant appearance and protect the thermal insulation from external influences.

Nuances

Remember that you are dealing with a modular system. And all fastenings should be as tight as possible, without any gaps.

Ceramics are a fragile structure; care should be taken; a strong mechanical shock can crack the product.

If the elements have chips or cracks, replace them immediately; they are no longer suitable for use.

Working with glue

A special acid-resistant glue is used. It is purchased in powder form and diluted with water in a ratio of approximately seven to one. Cooking time is only ten minutes.

Remember that before applying the surface must be thoroughly wetted with a sponge. And it is better to use glue with a reserve so as not to accidentally miss the gap

Instructions for laying bricks

Perhaps the most traditional chimney option. This option is used as an external casing, but we recommend that such pipes be lined with a stainless steel pipe.

Material Features:

- Resistant to extremely high temperatures. Modern fireclay bricks can easily withstand even 1000 degrees Celsius.

- The material perfectly absorbs and releases heat and accumulates it.

Features of a brick pipe: main disadvantages

This is the difficulty of assembling such a heavy structure if you do the assembly yourself. High cost – this is one of the most expensive options. And:

- The presence of vortex flows. Unfortunately, without professional intervention there is no way to avoid sharp corners in the final version. And this will not affect the output of combustion products one way or another, it will be slowed down. Some of them will accumulate inside.

- A brick chimney that is not lined with stainless steel pipes will absorb condensation, which will cause the internal walls of the chimney to peel off, ultimately leading to a pile of sludge at the bottom. Gradually, condensation will reach the outside, which will manifest itself as streaks.

- This is a very heavy and dimensional system that will require not just a platform, but a full-fledged separate foundation, designed at the stage of developing the house project.

Selection of material and preparation of solution

There are currently several types of bricks on the market. Red is the most average option. Burnt, as it is commonly called, is suitable as a material for a chimney, but it cannot be said that it is the best choice. It is better to choose a dark sample, which is also called burnt. It is the most fireproof and durable, designed for just such tasks.

But the pink color of the brick indicates that no strong heat treatment was used in its production.

A mixture of clay and river sand is suitable for the solution. You can add cement. It is important to choose a pure mixture, without impurities and small debris. When choosing clay, focus on the one that was mined at a significant depth of more than two meters.

The proportions are two to one, more sand accordingly. And remember that before work the mixture is soaked for two days. Only in this case will the correct consistency be achieved.

The order of laying the main parts

The first step is to lay out the nozzle pipe. This is a small element located immediately above the heating or furnace system. The height is small, 5-6 bricks will be enough. A regular rectangular shape is used.

Next, the fluff, the thickened part, is installed. It is laid out in gradual increments of diameter in half-brick increments. Its usual dimensions are 600 by 450 mm. And immediately behind it the main pipe begins, right up to the neck; a cap or umbrella is installed at the finish.

Disadvantages of brick and ceramic chimneys

Ceramic and brick chimneys have several main disadvantages:

- High cost of the products themselves.

Ceramic is 2-3 times more expensive than the stainless steel version. In the case of brick, choosing red brick (namely, it can meet the high temperature loads of sauna stoves), you must be prepared to pay a decent amount not only for the material itself, but also for the work of the craftsman. Laying out a brick chimney with your own hands is a very risky option, since in reality you may not achieve the desired condition in the steam room, as well as safe passage of the ceilings. The services of a professional in this matter are very expensive on the market.

- DIY assembly difficulty:

– Assembling ceramic chimneys requires the presence of the following tools: angle grinder (grinder), diamond disc, corundum disc, rubber mallet, tape measure, level, trowel, square, bucket (mixer, drill, marker, mounting gun).

– It is necessary to properly dilute the solution for ceramic pipes and separately for concrete or expanded clay blocks.

– It takes time to dry the product, especially with brickwork.

– The service life of the product and the safety of its use directly depend on the quality of the joints of ceramic pipes (or bricks). The joints must be leveled with a damp sponge; excess mortar is removed to make the seams smooth. It should be noted that the greatest risk of depressurization and fire hazard occurs at the joints.

- A chimney made of brick and ceramics must be laid at the design stage of the bathhouse/house. In ready-made buildings, it is sometimes very difficult or completely impossible to implement such systems.

- The high weight of the structures implies the presence of a foundation, which is not possible in the case of a finished structure.

Stainless steel chimneys

Today they are the best option. Lightweight and durable structure that does not require a foundation due to its relatively low weight. Metal pipes must be made of stainless steel with a chromium content of 13% or more.

Installation of metal sandwich chimneys

This type is a structure that consists of two pipes of different diameters - external and internal. The space between them is filled with non-flammable heat-insulating material with an operating temperature of up to 600°C - mineral wool made from high-quality basalt fiber.

Using a standard set of elements, you can create a smoke exhaust duct of almost any level of complexity. Each element is connected to the other using a bell-shaped design; they can be used for external and internal installation. The Ferrum company produces elements in the diameter range from 80 to 300 mm.

Design and installation require guidance on the rules for choosing the diameter and height of the chimney pipe, and taking into account the intensity and frequency of operation of the heat-generating apparatus. Sandwich chimneys provide increased fire safety, but they do not guarantee it completely. Therefore, passage through the ceilings requires the mandatory use of additional fire safety elements, namely polyurethane foam produced by Ferrum.

Installation of stainless steel chimneys

The elements are installed from the bottom up from the heat generating apparatus. If there is a mismatch in diameters, the joint is sealed with heat-resistant sealant. During installation, the inner pipe fits inside the previous one, and the outer pipe fits over the previous one. For better sealing of pipes, be sure to use a sealant with an operating temperature of at least 1000°C.

The joints of pipes and other elements (bends, tees, etc.) are fastened with clamps. They must be outside the ceilings. Wall brackets are installed for every two meters of the chimney, and the tee must have a supporting element. The fastening of parts to building structures must also be carried out using consoles and support platforms at least five meters apart. The fastening of connecting pipes must exclude the possibility of deflection.

Installation must be carried out on brackets through the wall or straight through the roof.

When deciding on the installation method, the following points must be taken into account:

- dimensions of the building - if small, then it is logical to make an external structure;

- the premises are old or being built from scratch.

Chimney pipe installation diagrams

Necessary elements included in the chimney kit.

The boiler adapter is the starting pipe component of the future chimney. It is necessary for condensate assembly, as it reorients the turn during installation.

The gate blocks the flow of flue gases if necessary, representing a valve with holes to prevent combustion.

The start sandwich is an intermediate element in the transition from single-wall to double-wall construction.

A ceiling-passage assembly (CPU) with mineralite is a mandatory element when maintaining fire safety at the point of passage through roof and ceiling slabs. PPU contains fireproof insulation material, an air layer and an area for placing an additional layer of thermal insulation.

The groove on the roof insulates the chimney from rain and snow. The increased rigidity of Ferrum structures will protect during snow melting, preventing leaks.

Clamps are used to fix the chimney relative to the installation plane. Steel fasteners are needed to position the system so that it does not rest on the stove or fireplace.

The standard set of modular stainless steel chimney system consists of:

- Adapter.

- Single wall pipe.

- Rotary gate.

- Start sandwich.

- Sandwich pipes (3-4 pcs.).

- Clamps of different lengths.

- Heading. Protects the insulation in the sandwich from precipitation.

- Tee sandwich. Serves to change the direction of movement of flue gases.

Installation of a chimney in ceilings for a house and bathhouse

The most fire-hazardous places in a bathhouse/house are passages through ceilings and walls. Below we will look at the passage options in more detail.

Passage through ceilings

For this task you will need a special unit, which you can make with your own hands..). The Ferrum company offers collapsible and ready-made options - without insulation and with additional insulation (basalt wool or mineralite).

If the passage unit passes dangerously close to the joists and rafters, you need to make it yourself and install a box made of wooden blocks lined with mineralite plates on the inside. And already install the PPU there.

If you purchased a ready-made unit, you must follow the instructions. Factory-made polyurethane foam can be of various configurations: “empty” or with additional insulation. In the first case, it is necessary to cover the base of the unit (stainless steel sheet) with basalt cardboard from the inside, and install the polyurethane foam itself in a box protected by mineralite sheets. We leave the distance between the pipe and the sheet empty. But the assembly itself must be covered with kaolin wool to a depth of 5-7 cm from the attic side; no more is needed to avoid overheating of the pipe.

If you purchased polyurethane foam with mineralite from the Ferrum company, then this unit can be installed without an additional insulated box, as in the first option. In this case, it is also necessary to fill the void inside the unit by 5-7 cm with kaolin wool. This additional insulation increases the fire safety of the passage unit.

The assembly is fastened with self-tapping screws or with a standard fastener if you purchased a factory product. Fixation is carried out to the ceiling from above. The stainless steel platform (the base of the unit) is attached with self-tapping screws to the lining after finishing.

When installing, you need to make sure that the hole coincides with the pipe, since tilting the system is prohibited, the maximum permissible error is 1 mm.

Passage through walls

An adapter is installed on the heat generator pipe to switch from the “smoke” assembly to the “condensate” assembly. Next is a heat exchanger or a single-wall pipe, and then a gate, an elbow and, at the end, a start-sandwich. Sandwich and polyurethane foam are always used in the section where the floor passes. After securing the sandwich tee, which is placed outside the building, a condensate drain is attached below, and there will be a head at the end of the pipe. In this case, the tee must be attached to the installation site, and the chimney trunk is mounted on wall brackets every 2 meters.

Roof passage

Roof cutting is a prerequisite for safe operation and the key to warmth and dryness in the house. Errors when arranging a passage through the roof usually lead to leaks, rotting and destruction of wooden roof structures, and improper fastening can cause a fire.

The sandwich chimney is brought out through the hole in the roof cut pipe, the gaps are treated with heat-resistant sealant with an operating temperature of up to 1000 degrees.

The upper edge of the roof trim apron should be placed under the overlying sheet of slate or metal.

When using a flexible cutting made of silicone or rubber, a hole is cut in the cap 1/5 smaller than its diameter. The cap of the roof cut is pulled over the pipe and the flexible apron is given the shape of a sheet. They are secured with self-tapping screws, having previously been coated with sealant. For a more durable fastening, it is sometimes necessary to strengthen the roof sheathing - this is done at the stage of cutting out a hole in it.

- The length of the channel must be at least 5 meters.

- Lack of many turns. If there are more than three, then you need to change the project.

- If there is a horizontal path, then its length should be no more than one meter.

- The diameter of the pipe should not be narrower than the connecting pipe.

- Ideally, the chimney should be vertical throughout. But sometimes this can be difficult or impossible to achieve. In this case, tees and transitions (elbows) are used. If your channel has at least one 90* transition, then you need to extend the pipe by 1 m, if there are two transitions (two corners), then by 2 m. If you used a 45* transition, then two such angles - this is plus 1 m in height.

Conclusions and useful video

It should not be forgotten that fulfilling all these requirements is a guarantee of the safety of your health and property. Therefore, it is worth approaching this problem as seriously as possible. And first thoroughly study how to install a chimney correctly and only then start working.

Any stove, fireplace or boiler installation designed to burn fuel must have a chimney. Today, manufacturers present a wide range of materials necessary for the construction of a vertical channel. Modules, or, as they are also called, sandwiches, are in great demand. The article will tell you about the design of such a product and reveal important aspects that you need to pay attention to when choosing products for each individual case. In addition, the stages and important aspects that will help you install sandwich chimneys with your own hands will be discussed.

For proper installation of the structure, there are specially developed regulations that must be followed:

- SNiP 41-01-2003; VDPO (RULES FOR WORK, REPAIR OF OVENS AND SMOKE CHANNELS).

- SP 7.13130.2009.

The main task of the chimney is to remove the products of the chemical oxidation reaction of the substance and provide optimal draft to support the combustion process. When installing a sandwich system, an important point is the height of the structure and its diameter. The level of traction directly depends on these parameters.

When installing a channel made of sandwich pipes, the following rules must be observed:

- The height of the chimney from the heating device to the head must be at least 5 m.

- To determine the elevation above the parapet, a special scheme is used.

- When the height of the chimney is more than 1.5 m, it must be additionally secured with a brace.

- The elevation of the canal above the roofs of nearby buildings is from 1.5 m.

- To ensure unhindered removal of condensate formed and when cleaning the smoke channel, it is necessary to provide for the presence of plugs in the design, equipped with a condensate drain.

- If the roof is made of flammable materials, a spark arrester should be installed in the chimney. For its production, a mesh with a cell size of no more than 5 by 5 mm is used.

- Under no circumstances should the diameter of the channel for removing combustion products be narrowed, but its widening is permitted. For example, if a heating stove requires a chimney with a diameter of 115 mm, then a cross-section of 110 mm is unacceptable, but 120 mm can be used. This requires installing an adapter from a smaller diameter to a larger one.

- It is important that the section of the smoke channel, which is horizontal, does not exceed 1 m.

- The connection points of the system elements that ensure the removal of combustion products should not coincide with the passages in the wall, as well as ceiling and roof passages.

- Tees and bends are installed so that the weight of the smoke channel elements does not create unnecessary load.

Sandwich pipe assembly

Before installing the system, you must assemble it correctly:

This completes the work of assembling the sandwich system. To attach the tee, umbrella, tip and corner, you can use the same operating principle. The chimney is fixed to the wall using brackets. The distance between them should be about 2 m.

The places where the tee is located are secured using brackets, which helps reduce the load. If necessary, you can also use horizontal chimney links. Their size should be within 1 m.

It should be remembered that during production any sandwich pipe is covered with film. It must be removed immediately after completing assembly of the product.

If it becomes necessary to install a chimney inside a box or between walls, two windows measuring 150 cm² are made on the outside of the side structure.

One hole should be located at the top and the other at the bottom. In the case of a closed setback, it is important that the assembled floor is made of non-flammable material.

How to get around ceilings

Situations often arise when the path of the chimney pipe to the surface coincides with the location of the enclosing structures. You can bypass them using a box that has holes where you need to insert a pipe.

The thickness of the hollow product must be 7 cm greater than the corresponding overlap, which provides fire protection. For complete safety, the box is firmly attached to the enclosing structure.

There should be no joints in the pipe. Before installing the dividing box yourself, you need to mark it using a marker. It is at this point that the saying “Measure twice, cut once” is very relevant.

Only after choosing a suitable box and the correct location of the channel can you begin to make holes in the ceiling.

Pipe insulation

When the installation of the box and pipe is completed, complete insulation of the last element is necessary. Here it is advisable to use a foil mat based on basalt, which is treated with mastic that protects against fire. The hole in the roof is also closed using mineral wool. All gaps in contact with the pipe are filled with this insulation.

Stages of bringing the chimney to the roof

To bring the sandwich pipe to the upper structure of the building, a special link is used, called a roof cut. The element is selected based on the slope of the roof. Having determined this indicator, it will not be difficult to complete the work, which is carried out in the following three stages:

- Markings are made on the inside of the roof.

- The size of the cut hole must match the diameter of the chimney pipe.

- Insulation work is being carried out. The bottom line is that a galvanized sheet with a hole already made for a vertical channel is attached to the inside of the roof. Next, the pipe is brought out. A roof trim is mounted on top. First, the number of links necessary to create the required height is placed above it, then an umbrella is attached, the main function of which is protection from precipitation.

Retreat: what is it?

Self-installation of a sandwich chimney requires a setback. This is a special space located between the wall and the vertical channel, the size of which is indicated in the table.

If the distance from the outer surface of the heating device to the side structure is completely closed, then two holes are made above the stove, located at different levels. The cross-sectional area of each is equal to 150 cm². The placement of the installed floor should be 7 cm higher than the original one. In this case, a floor covering made of non-combustible material is used.

Support platform

The choice as to which chimney design to give preference (with or without the “Cantilever Bracket” support platform) depends on the type of heating device and the location of the chimney.

In the absence of such fastening, an exclusively flat vertical channel can be used, which will rest on the heating device. In other cases, its use is a necessary condition.

It is important that the “Cantilever Bracket” element is located every 5 m along the pipe.

Stages of installing a chimney

The vertical channel must be fixed in such a way that it can withstand the effects of wind or the load of its own weight. In addition, it is necessary to prevent the formation of deflections in the structure. In this case, a wall mount is used, which is distributed every 2 m.

Danger of temperature movement up and down

A pipe 6 m long will change by about 10 cm under the influence of high and low temperatures. This indicator should be used as a starting point. If the steel chimney is mounted rigidly and does not slide under the influence of temperature conditions, several problems may arise, including the following:

- modification of the smoke channel (bending occurs between the connections);

- deformation of weak floors;

- breaking out fasteners.

If the furnace is moderate, this does not pose any danger, but at extreme temperatures there can be disappointing consequences.

The opinion of one stove maker

If it is necessary to create two bookmarks one after another during afterburner, the pipe is subjected to strong bending. In this case, the expansion reaches more than 10 cm.

With four hours of active work the structure can heat up to a dark red color 3 m up. In addition, in this case, it is possible that the welded set may fly off. But this is taken from the experience of not a standard sandwich pipe, but a homemade internal double product made of stainless steel, with walls 3 mm thick, and externally it is thin-walled. Everything was attached to the supporting side structure using corners.

One winter I decided to dry a couple of slats. He opened the doors and kept throwing it into the oven. After four hours, the chimney fell apart at one of the joints. The pipe was bent due to temperatureto such an extent, which tore the through bolt out of the wall by the roots. In this regard, the temperature regime should be treated with special attention and caution.

Content

Before installing a heat source that requires gas, solid or liquid fuel in a private house, bathhouse or outbuilding, it is necessary to prepare a design for a combustion product removal system. Today, classic designs made of brick or asbestos-cement pipes are replacing convenient and practical chimneys made of stainless steel, for the installation of which ready-made elements are used.

Types of stainless steel chimneys

You can connect any type of heating boiler, metal or compact brick stove, or fireplace to the universal modular chimney. You can assemble the smoke channel yourself by choosing the right system. They differ in design, purpose, and metal characteristics.

Main advantages

Chimneys made from asbestos-cement pipes were in demand due to their low cost, despite their low practicality. Brick structures are still actively used today, including due to their solid and impressive appearance, but they are increasingly being modernized with the help of stainless steel inlays. The list of advantages of a chimney made of stainless steel includes:

- Light weight. The chimney does not require a foundation, which reduces the cost and speeds up installation work.

- Corrosion resistance. Stainless steel is resistant to acids contained in smoke condensate and dangerous for brick and asbestos cement.

- Resistance to temperature changes. The metal can withstand cooling to low temperatures on frosty days and heating by flue gases up to 800 degrees Celsius or more.

- Effective chimney removal. Good traction is facilitated by the round cross-section of the pipe.

- Low maintenance. There is practically no soot deposited on the internal walls of the chimney channel (unlike rough walls made of brick or asbestos cement), so it rarely needs cleaning.

- Easy installation. The configuration of standard elements allows for quick assembly of pipes of any length.

- Maintainability. The modular system allows, if necessary, to change only the element that has failed, which reduces the cost of operating the smoke exhaust system.

- Long service life (subject to the correct selection of manufacturing materials and proper installation).

- Versatility. A stainless steel chimney is suitable for any type of heating unit.

- Freedom of installation. It is not necessary to mount a strictly vertical structure; inclined elements and turns are allowed, which simplifies the search for a convenient place to install a boiler, fireplace or stove. A pipe with internal insulation can be installed outside the building - in this case there will be no need to install passage units through the floors and roof.

- Affordable price.

Chimney components

Chimney components Types of pipes

Stainless steel is used to make three types of chimney pipes, each of which has its own specific application. It is important to take this into account when choosing an option for a residential building, bathhouse or other building. Manufacturers offer the following types of designs:

- single-walled (single-layer);

- corrugated;

- sandwich pipes.

Let's take a closer look at which stainless steel chimney pipe would be more appropriate for use in certain conditions.

Single wall pipes

Single-layer systems are made of stainless steel sheet with a thickness of 0.6 to 2 mm. The option is characterized by a low price, but the scope of application of such a pipe is limited.

It can only be installed inside a warm room, and the outer part of the chimney should be insulated. This is due to the fact that contact of heated metal with cold air leads to increased formation of condensation. This reduces the efficiency of the heating unit, entails excessive fuel consumption, and reduces the service life of the stove or boiler.

Single wall pipes

Single wall pipes Single-wall steel pipes are most often used to arrange sleeves when modernizing brick smoke ducts. Lining extends the service life of a brick chimney due to protection from destructive condensation, and reduces the need for maintenance, since soot does not build up on the walls. Manufacturers offer single-layer stainless steel pipes of different sizes, round and oval sections, which allows you to choose the best option for a particular brick chimney.

A single-layer pipe can also be used in conjunction with a water heating system for a small room - a garage, workshop, washing department of a bathhouse. In this case, a water jacket is mounted on the chimney pipe, to which the supply and return pipes are connected. Also, the thermal energy of exhaust flue gases can be used to heat a compact room by running a single-layer pipe at an angle along a long wall.

Installation of a chimney made from a single-layer stainless steel pipe requires strict adherence to fire safety rules when arranging passages through the floors and roof. The ignition of soot in a pipe (especially when using a solid fuel stove) can heat the metal to critical temperatures and lead to the fire of wooden structures.

Corrugated pipes

The corrugated stainless steel pipe is designed for installation of curved transitions if the outlet pipe of the boiler or furnace is located away from the vertical chimney channel. Also, when lining a brick chimney, a corrugated pipe can be used inside a structure that has bends.

Corrugated pipes

Corrugated pipes It is necessary to choose a high-quality corrugated pipe made of stainless steel that can withstand heating up to 900 °C. Corrugated elements are used inside and outside the building, but in the second case they require insulation to avoid the formation of condensation due to contact of the metal with cold air.

Note! A chimney project using corrugated elements may be rejected by regulatory authorities, since there are complaints about the strength and heat resistance of corrugated pipes.

Sandwich systems

A two-layer pipe, which is a sandwich with a non-flammable heat insulator between metal shells made of stainless steel, is produced in the form of straight and shaped elements for assembling a chimney of any configuration. Due to the thermal insulation layer, this is the most practical option for a smoke exhaust duct, because:

- increased safety is ensured (the outer walls of the system do not heat up to dangerous temperatures, the heat insulator itself is resistant to ignition);

- allows you to install the chimney outside the building;

- a minimum of condensation is formed (the internal pipe through which combustion products move does not come into contact with cold air);

- there is no unnecessary heat loss, which allows the heating unit to operate in optimal mode, without excessive fuel consumption;

- the system is installed quickly and without the hassle of pipe insulation.

Sandwich system

Sandwich system Sandwich pipes are universal; they are used for installation on gas or solid fuel boilers, fireplaces and stoves of any type.

Range of modules

Installation of a stainless steel chimney is carried out using ready-made modules of various types, so it is not difficult to do it yourself. Manufacturers offer the following elements:

- Straight pipes. The part can have a length from 33 to 100 cm. The elements are firmly connected to each other through bell-shaped coupling; installation does not require the use of additional fasteners.

- Bends 45°. They are used when it is necessary to perform a deviation from the vertical.

- 90° bends. Used to transition between vertical and horizontal sections of the structure.

- Tee 45° or 87°. Designed for installation of a condensate assembly unit, it can also be used to connect two heating units to a common chimney.

- Condensate collector. It is mounted at the lower point of the main vertical channel; moisture condensed during cooling of the flue gases flows into it.

- Revision element. Installed in places where there is a higher risk of soot accumulation, to check and clean the chimney system.

- Penetrations. Special elements for arranging the nodes for passing pipes through floors and roofs help ensure fireproof insulation of structures, roof tightness, and an attractive appearance.

- Cap, spark arrester and other elements for installation on the top of the chimney. They protect the system from the penetration of precipitation, the occurrence of the reverse draft effect, and from sparks hitting the roofing.

Chimney elements

Chimney elements Material selection

To make stainless steel pipes for chimneys, various grades of steel are used. The service life of the product and its resistance to burnout when soot ignites in the pipe depend on the choice. The higher the quality of the steel, the more expensive it is. Be sure to take into account the frequency of operation of the chimney - the requirements for the chimneys of boiler units operating around the clock during the heating season are higher than for the pipes of sauna stoves that are fired from time to time.

| steel grade | Characteristics |

| 439 | Titanium and aluminum are used as additives. The material is resistant to acid corrosion and can withstand heating up to 850 °C. |

| 430 | Mainly used for the manufacture of casings and other elements that are not directly exposed to high temperatures and aggressive environments. |

| 409 | High heat resistance and acid resistance, can be used for chimney pipes of solid fuel stoves and fireplaces. |

| 304 | High strength, good weldability. It serves as a cheaper analogue of steel 316, somewhat inferior to its parameters due to the low amount of alloying additives. |

| 310S | A universal material due to its ability to withstand heat up to 1000 °C. |

| 316 | Thermal stability and chemical resistance are ensured by the addition of molybdenum and nickel. The material is suitable for boiler pipes of any type. |

| 316i, 321 | Pipes are universal, flexible, and corrosion resistant. Can be used for wood stoves. |

Stainless steel material selection

Stainless steel material selection In private housing construction, stainless steel pipes of grades 409, 430, 439 are mainly used. With periodic operation (weekly heating of a sauna stove with wood), such a system will last about ten years. On boilers in load mode 24 hours a day, the average service life will be 2–3 years. To extend the service life of the chimney system, it is recommended to install it from 3XX stainless steel.

Chimney design

The design of a system for the removal of combustion products begins with the selection of a modular system and preparation of the project. Since the requirements for chimneys for gas boilers are increased, their design must be submitted to technical supervision services and permission for installation work must be obtained.

- The minimum permissible total height of the chimney is 5 meters, otherwise the draft will be insufficient.

- The maximum length of the horizontal section of the channel is 1 meter;

- Outside the building and in unheated rooms, the chimney must be thermally insulated, unless it is a sandwich system.

- The height of the chimney pipe above the roof:

- at least 50 cm if the roof is flat or the distance from the ridge of the pitched roof to the pipe is less than 150 cm;

- flush with the ridge or higher, if the distance from the pipe to the ridge is from 150 to 300 cm;

- below a line with a slope of 10° from the horizon of the ridge, if the distance between the ridge and the pipe is more than 300 cm;

- above the level of buildings attached to the building.

- If the roofing material is not resistant to fire, regulations require the installation of a spark arrestor.

- The minimum distance between a single-wall stainless steel pipe and the floor and roof structures is 1 meter; (for a sandwich - 20 cm), the pipe must be insulated with non-flammable material (basalt wool).

- A gap of 13 cm is required between the pipe and the roof (including those made of non-combustible materials).

- Pipe connection points should not be located inside structures (ceilings, walls). The minimum distance from the joint to the structure is 70 cm.

- Horizontal and inclined sections of the chimney duct must be assembled “according to the smoke” - the next element is put on the previous one so that combustion products are removed as efficiently as possible. The vertical channel is mounted “along the condensate” - so that the moisture flows freely, the subsequent element is inserted into the one located below.

- Throughout the entire length of the chimney duct, its internal diameter must be no less than the diameter of the outlet pipe of the heating unit.

- No more than three turns are allowed along the entire length of the chimney.

Chimney installation diagram

Chimney installation diagram There are various installation schemes for stainless steel chimneys. In the case of using a sandwich system, it is easier to bring the pipe outside so as not to punch holes in the ceilings and roof. The pipe is secured to the external wall using special brackets. The external chimney can also be mounted inside a metal profile frame to prevent accidental mechanical damage, especially in the case of high wind loads.

Installation features

When installing stainless chimneys, it is important to follow the rules on the basis of which the system is designed. The entire range of work can be completed independently, paying special attention to the following points:

- A standard adapter must be attached to the nozzle of the heating unit, and not a homemade replacement, as this can lead to problems in the operation of the chimney;

- additional sealing of pipe joints is required to prevent carbon monoxide from entering the room and to ensure good draft;

- the sealant must be heat-resistant and withstand heating up to +1000 ... +1500 degrees Celsius;

- brackets for external installation of the pipe are fastened in increments of no more than two meters, and fastening points must be provided at the point where the chimney passes through the wall and next to the inspection compartment.

Types of installation

Types of installation Thanks to the special configuration of the edges, you can quickly connect the modules, creating a solid structure. Details on how to properly assemble a stainless steel chimney can be found in the video.