Houses with fireplaces, stoves, and heating boilers are equipped with chimneys used to remove combustion products to the outside. Lining a brick chimney is recommended for safer, more efficient operation. The brick has a rough surface, which favors the formation of condensation, the settling of soot and soot in a dense layer, and this leads to rapid contamination and deterioration of the chimney. Lining can be done with your own hands using a stainless steel pipe.

Preventive inspections of chimneys should be done before the start of the heating season.

Main advantages

Lining a brick chimney will provide:

- Reducing the release of condensate and discharging it into a special container or sewer system.

- Optimal level of draft, protection from smoke in the room.

- Free access for cleaning from combustion residues.

- The tightness of the exhaust duct.

- Protection against heat loss.

- Long service life, because it protects the inner surface from moisture, accumulation of soot, and soot that corrode the brick.

Sleeving methods: pros and cons of each

Lining a brick chimney is possible in one of the following ways:

For such work, you can use a stainless steel pipe.

Often the work is done using Furan Flex polymer products.

- Installation of stainless steel liners inside the chimney. This method can be called universal, suitable for any heating systems. The downside is that a stainless steel pipe has thin walls, which quickly burn out under the influence of high temperatures.

- FuranFlex is a system made of polymer materials. This method is recommended when using gas heating boilers characterized by a low temperature at the outlet of combustion products. Polymers are designed for temperatures not exceeding 250°. Disadvantages of the method: it is impossible to do the installation yourself; this requires certain knowledge and skills; the cost of building materials is high.

Materials and tools

It is better to avoid installing a corrugated product, since it will become clogged very often due to its structure.

It is better to avoid installing a corrugated product, since it will become clogged very often due to its structure. The chimney liner consists of installing a stainless steel pipe inside the exhaust duct. Its smooth surface will ensure rapid heating, which reduces the formation of condensation and the release of soot along with smoke. The sleeve must be round or oval in cross-section made of stainless steel: when using solid fuel - AISI 321 or 409, thickness of the sleeve - 0.8-1 mm, in case of gas heating - AISI 304, thickness - at least 0.5 mm. The use of flexible stainless steel pipe is not recommended, as soot and condensation will accumulate on the corrugated inner surface.

How to install?

The chimney liner is usually installed during the construction of the exhaust duct. If installation is done later, during the operation of the chimney, the chimney is first inspected and cleaned. The tightness, operability of the structure, and the strength of the brick are also checked. The dimensions of the sleeve are calculated: section thickness, length of the pipe and outlet. The thrust force, the type of fuel to be used, and the temperature at the outlet of the combustion products are determined. With a correctly calculated diameter of the exhaust channel, the draft improves with increasing its height.

According to the rules for the production of chimney and stove works from 2005, chimney structures are installed near internal walls and partitions made of fire-resistant materials.

You built a brick chimney, paying more attention to aesthetic purposes. Now the craving is gone. The problem can be solved by installing a new exhaust duct inside the shaft. We offer a step-by-step look at how to line a chimney using liners.

Principle of operation

When the boiler is burning, the temperature at the bottom of the duct is higher than at the outlet. Due to the difference, a pressure difference is formed. The higher this indicator, the better the traction. Combustion products are freely discharged to the street, and oxygen enters the firebox to support combustion.

Requirements for the exhaust duct

Good traction is maintained due to the tightness of the structure, as well as due to the low accumulation of soot and. These parameters are the basic requirement for all chimneys. It is important to correctly calculate the cross-section so that there is no smoke inside the room.

The essence of the sleeve and its advantages

Before you rush to reconstruct a chimney, you need to understand what lining is, as well as find out the advantages of the process.

Most chimneys have a rectangular channel cross-section. For masonry, ordinary red or decorative bricks are used. Over time, large soot build-ups appear inside the channels, efficiency decreases, and traction completely disappears. The problem lies precisely in the shape of the section, as well as the rough surface of the brick.

Round and oval canals have smooth inner walls. Soot does not cling to the walls.

In order not to build a new chimney, they came up with lining. The procedure involves inserting a pipe inside the channel without destroying the brickwork. The best option is a stainless steel sleeve, but ceramics, asbestos or polymer can be used.

Benefits of lining the chimney duct:

- traction is enhanced due to the smooth surface of the sleeve;

- heat losses are reduced, efficiency increases;

- no turbulence occurs inside the round channel;

- the service life of the channels increases due to the resistance of the sleeve to condensate;

- the tightness of the chimney improves.

The sleeve insert forms a new channel for the removal of combustion products, and the brickwork acts as a casing.

Is there a need for a sleeve?

It is better to install the sleeve during the construction phase of the building. The insert is bricked up as the shaft is laid out from brick. If you didn’t do this initially, you will have to return to the process over time. Cladding a completed house is more difficult. We will have to partially destroy the masonry, break the decorative cladding and restore everything again.

The urgent need for lining brick chimneys is caused by the following reasons:

- Initially, the combustion product removal system was designed and built with errors;

- constant use of a fireplace or stove connected to a brick chimney is assumed;

- long channel length;

- if according to the project the mine should be lined, but this was not done;

- the shaft passes through a cold attic and due to the temperature difference, condensation forms;

- the chimney is made of brick inside the outer wall of the building;

- condensation streaks appear from the seams of the brickwork of the shaft;

- depressurization of the smoke channel;

- the shaft quickly becomes clogged with soot and requires frequent cleaning;

- The smoke exhaust passages were laid not by professional stove makers, but by inexperienced masons.

In all other cases, the owner performs the sleeve at his own request.

Three common sleeving methods and materials used

The main essence of the sleeve is the insertion of the liner inside the brick shaft. Sleeves differ in material, size, and shape. The basic principle of installation is the same, but there are nuances.

Stainless steel

The sleeves are characterized by a long service life, resistance to high temperatures and condensation. Stainless steel pipes are suitable for shafts of any length and shape.

Stainless steel liners differ in design:

- Round pipes are produced with a cross-section from 6 to 100 cm. The wall thickness depends on the metal used and ranges from 0.5–1.5 mm.

- Rectangular pipes are used less frequently. When required, inserts with a wall size of 14×27 cm are used.

- Oval pipes are made of stainless steel with a thickness of 0.5–0.6 mm. Running sizes are 20×10 and 24×12 cm. The cross-section approximately corresponds to a round pipe with a diameter of 15 and 20 cm.

- Corrugated hoses are made in two layers from different grades of stainless steel. The cross-section varies from 8 to 35 cm. When installing a flexible stainless steel chimney, do not bend the corrugation with a radius less than two pipe diameters.

Of all the options, the corrugated sleeve is considered the most unreliable. Two-layer stainless steel burns out in four years from exposure to high temperatures, and soot lingers on the ribbed walls.

Polymer sleeve

The sleeve is made of fiberglass mesh impregnated with polymer resin. A one-piece hose is inserted into the shaft without the use of connecting segments. If necessary, use shaped parts. Maximum sleeve length – 60 m. Thickness – from 8 to 50 cm. Service life – up to 30 years. For high-temperature and low-temperature boilers, hoses with different compositions are used.

FuranFlex polymer systems for gas boilers, fireplaces and stoves are popular in Russia.

FiTFiRE liners are used for low-temperature boilers. FiTFiRE HT 1000 is suitable for fireplaces and stoves.

Sleeve sleeve allows you to get a solid channel without dismantling the brickwork of the shaft. The liner is resistant to condensation and is capable of bending at turns at an angle of 30 0 . Disadvantages include high cost, as well as the impossibility of independently installing a smoke exhaust duct without the skills and availability of special equipment.

Ceramics

Ceramic liners are considered reliable and durable. For lining, they are more often used when restoring destroyed mines. Elements are available in round and rectangular shapes. The connection takes place using a socket or tongue-and-groove lock. The diameter of the sleeves is from 12 to 45 cm. Straight pieces of pipe are produced in lengths of 33, 66 and 133 cm. Wall thickness varies from 4 to 20 mm.

Ceramics are not afraid of soot fire. The downside is the high cost and weight. Installation is not complete without dismantling the chimney shaft.

Features of installation of liners made of different materials

In modern construction, stainless steel, ceramics or a polymer sleeve are used to reconstruct the chimney. Ceramic liner and polymer are difficult to install. Most often, when lining chimneys with your own hands, stainless steel is used.

Preparatory work

Regardless of the type of liner chosen, a number of preparatory measures are performed before starting liner:

- Using a powerful flashlight, they inspect the smoke shaft from the inside. The degree of destruction, soot contamination, the presence of fallen pieces of mortar, bricks, and bird nests are determined.

- Use metal scrapers, brushes and other devices to clean the chimney. Bricks protruding from the masonry will prevent insertion of the liner. They try to knock down all the protrusions with a hammer or pry bar.

- Measure the length as well as the diameter of the chimney. The dimensions are transferred to the diagram, indicating all rotations and degrees of angles.

- The part of the chimney adjacent to the boiler or stove is dismantled. The installation of the shaped element will begin from this place.

- The bottom of the smoke shaft is cleared of debris and leveled if necessary.

After the preparatory measures have been carried out, the inserts necessary for the sleeve are purchased.

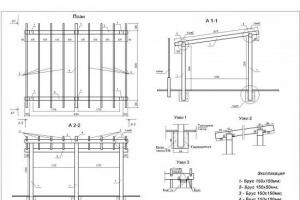

Installation of a stainless steel liner of round, rectangular or oval cross-section

Sleeving a small shaft with stainless steel without turning is carried out according to the following principle:

- All elements of the sleeve are assembled into one structure. The joints are treated with heat-resistant sealant, and the top is wrapped with aluminum-based adhesive tape.

- Two belts, cables or strong rope are secured to the bottom of the pipe with a clamp.

- The sleeve is carefully lowered down the shaft until it touches the bottom. If the length of the chimney is short, a lightweight stainless steel pipe is immersed by hand without using cables.

- The liner from below is connected to the inlet of the boiler or furnace and a condensate collector is installed. The sleeve is removed from the street above the brickwork of the chimney, and a protective cap is put on top.

Stainless steel lining of a long chimney with turns is carried out differently:

- The smoke duct is dismantled at the entrance to the boiler, as well as all areas where shaped connectors will be installed.

- First, the lower part of the sleeve is assembled from flat sections of the pipe up to the first shaped connector. The liner is lowered to the bottom of the shaft, connected to the inlet of the boiler or furnace, and a condensate collector is installed below.

- A shaped connector is installed on the second free end of the steel sleeve. A flat section of stainless steel is connected to it until the next turn of the shaft. The procedure is repeated until the sleeve is removed from the shaft.

The area where the pipes join is similarly reinforced with heat-resistant sealant and wrapped with aluminum tape. A head is installed on top.

Installation of corrugated stainless steel hose

The lining of a flue with a corrugated stainless steel is carried out in a similar way. The difference is the arrangement of the lower and upper exits from the mine. After installing the flexible hose inside the smoke channel, a rigid transition made of stainless pipe is attached from below. This section is used to connect the hose to the inlet of the boiler or furnace. A condensate collector is installed below.

At the upper exit from the smoke channel, the corrugation is placed above the masonry about 30 cm. To securely fasten the head, the exit can be made by extending a rigid section of stainless pipe. Upon completion of the lining, the brickwork of the chimney duct is restored.

Installation of ceramic liner

Lining with ceramic liners is more difficult. The process consists of the following steps:

- A roller mechanism is fixed to the holes of the condensate collector. The element in the sleeve is a load-bearing structure, and the first one descends into the chimney to a depth of 30 cm. Ceramics are heavy. For a safe descent, it is best to use a winch.

- The upper end of the condensate collector is treated with sealant. Using a socket or tongue-and-groove lock, a flat section of the pipe is secured.

- To connect the boiler, a hole is cut out on a flat ceramic sleeve using a universal fitting. A winch is used to lower part of the liner into the shaft. The next element is fixed to the end of the first pipe in a similar way. During descent, make sure that the sleeve with the hole for the fitting does not turn in the other direction relative to the boiler inlet.

When the condensate collector reaches the bottom of the shaft, it is connected to the boiler inlet. From above, a ceramic pipe is installed above the brickwork. The protrusion is made equal to the height of the cover plate.

Installation of a polymer sleeve

To line chimneys with a polymer sleeve, special equipment will be required. Initially, the liner resembles a coiled hose. The hose is lifted to the roof of the building, inserted through a channel to the bottom of the shaft, connected to a compressor and air is supplied. Under pressure, the soft walls of the stocking will straighten out.

When the hose takes on the internal shape of a channel, steam is supplied instead of compressed air. The polymer first softens and then hardens. A condensate collector is installed from below. At the exit from the shaft, the excess piece of the sleeve is cut off, and a head is installed on top.

A fireplace (stove) is an indispensable attribute of a modern country house. To safely remove carbon monoxide from the living space, which is inevitably formed during the combustion process, a special exhaust duct - a chimney - is installed in the house.

To ensure the complete safety of residents, you need to know how to lay a brick chimney and, during subsequent operation, maintain it in a timely and correct manner.

Features of the smoke exhaust channel

Design

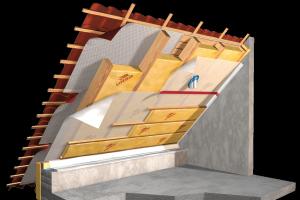

The basis of the design of any chimney is a vertical, straight channel, which, through a transition device, docks directly with the heat source. After passing through the roof of the house, the channel with the help of another vertical pipe, covered with thermal insulation to minimize the formation of condensation, is erected above the ridge of the roof of the house.

To prevent precipitation from entering the pipe, a protective umbrella (deflector) is installed at its upper end.

Principle of operation

In its lower and upper parts, the exhaust duct has different air temperatures and, accordingly, different pressures. At the same time, the pressure at the outlet of the chimney is significantly less.

Therefore, due to the pressure difference, the air flow in the pipe constantly moves from bottom to top. The presence of draft determines the correct operation of the chimney.

Requirements for the exhaust duct

The answer to the question of how to lay a brick chimney naturally follows from the requirements that it must meet.

A channel is efficient, reliable and of high quality if it:

- provides good reverse traction;

- guarantees complete absence of smoke in the living space;

- characterized by minor soot deposits;

- has a minimal level of condensation formation;

- has a long service life.

Required building material

Before you unambiguously decide on the question of what kind of brick the chimney will be made of, it is necessary to understand what type of stove or fireplace will be installed, what type of fuel it will operate on, and to what temperature the exhaust gases will be heated.

The following materials can withstand high temperatures:

- building brick (see article for more details);

- heat-resistant steel;

- enameled steel;

- ceramics;

- polymers, the price of which is much higher.

Smoke, depending on the fuel used, heats up to 600Cº on average, so double sand-lime brick 150 m is often used to build a chimney.

Chimney liner

Brick chimneys that decorate homes are not ideal smoke exhaust channels.

They have the following disadvantages:

- the required level of traction is not provided;

- due to the irregular shape of the exhaust duct, conditions for good smoke passage are not provided;

- low efficiency.

The highest efficiency is for a round (oval) chimney with a perfectly smooth surface. Therefore, to give the chimney the necessary properties, a brick chimney is lined.

To carry out this procedure, special pipes made of stainless, heat-resistant, acid-resistant steel are used. They must be laid in a brick channel at the construction stage or in an already laid chimney.

Stainless steel pipes must be resistant:

- to sudden changes in temperature;

- exposure to an aggressive environment.

Advantages of sleeving

As a result of work on lining the smoke channel:

- draft is significantly improved due to smoother, shiny walls compared to brick or asbestos pipes. It is known that the mirror surface provides the lowest coefficient of friction of smoke against the pipe walls;

- heat loss becomes smaller due to the formation of an air gap between the walls of the stainless pipe and the brick channel;

- the possibility of the formation of unnecessary air turbulence is eliminated due to the use of round pipes with smooth walls;

- increases the resistance of the smoke exhaust channel to condensation and aggressive acidic substances, which are part of smoke. Condensation, turning into ice, significantly reduces traction.

Installation of a smoke exhaust duct

The simplicity of the chimney design allows, if you have some experience, to calculate and make it yourself. Laying a brick chimney with your own hands will significantly save financial resources.

A short instruction will help you design and build a chimney correctly, as well as line it.

- At the first stage of the work, it is necessary to correctly calculate the main characteristics of the smoke exhaust duct:

- traction force;

- pipe diameter and height.

With the correct diameter, as the height of the chimney increases, air circulation also increases. The basic requirements for how to build a brick chimney, as well as provisions for the choice of material, structure size and installation procedure, are set out in the main regulatory document SNiP 41-01-2003 “Heating, ventilation and air conditioning”.

Note!

If the cross-section of the chimney is very large, the draft may not increase with increasing its height. The effect of a “choked” chimney occurs.

- Before making a chimney out of brick, it is necessary to provide for its lining at the construction stage;

- Installation of smoke exhaust pipes begins from the heating facility. Each subsequent pipe link is inserted into the previous one. To protect the structure from moisture, it is necessary to use a special heat-resistant sealant;

- All joints are fixed using clamps;

- When laying, it is necessary to completely prevent the pipes from coming into contact with other communications (gas, water, electrical wiring, etc.);

- It is necessary to provide for the installation of a door for cleaning the smoke exhaust duct during its operation;

- If pipes are planned to be located near flammable finishing items, they must be insulated;

Advice!

High-quality chimney insulation not only prevents the formation of condensation, but also contributes to faster heating of the home.

- When laying a stainless pipe through the roof, it must be insulated with mineral wool;

- When laying bricks, special attention is paid to the evenness of the walls and the accuracy of the corners;

- During laying, it is necessary to provide technological holes and a place for installing the door to clean the channel from the formed soot;

- The outer part of the chimney;

- It is necessary to build the chimney as vertically as possible. The fewer turns and inclined sections, the more efficiently the smoke will be removed from the outside. The length of horizontal sections should not exceed one meter.

Conclusion

In the video presented in this article you will find additional information that is very close to the topic and will allow you to more clearly answer the question of how to line a brick chimney. A correctly calculated and constructed chimney in compliance with all fire safety regulations will provide the necessary comfort and coziness in the house.

Chimney lining is carried out in cases where the previously built brick chimney of a stove or fireplace began to lose its throughput, often becoming clogged with combustion products. At the same time, the draft is significantly reduced, due to which smoke periodically fills the rooms of the house, and the heating efficiency sharply decreases.

There are several ways to solve this problem. But one of the most effective is to “ennoble” the internal surfaces of the brick walls of the chimney shaft with special liners. These sleeves have smooth internal surfaces, so that smoke does not encounter obstacles and does not linger in the channels. It smoothly “slides” along the smooth walls, coming out, while leaving virtually no fuel combustion products on the surface of the liner.

What is lining and when is it necessary?

If we define in simple words what sleeving is, then this term can be explained very briefly. This operation means installing an additional pipe into the chimney duct of an existing brick chimney.

When installing a liner inside the chimney, which is more often called a sleeve, all the smoke from the combustion chamber is directed into it. That is, it has absolutely no contact with the surface of the old walls of the main brick structure.

This repair method is applicable not only to chimney pipes, but also to air ducts of ventilation systems.

It is not at all necessary to wait until the chimney becomes unusable. Many stove makers recommend installing a liner during the construction of a stove or fireplace. In addition to improving traction, such a measure will help protect the brickwork from the destructive effects caused by combustion products in combination with temperature changes and condensation.

It is important to understand the situation correctly - if a brick heating structure is used intensively, then sooner or later you will still have to carry out such lining. However, it will be much more difficult to install the liner into the chimney duct of an already operating stove. Judge for yourself - you will have to remove the cladding from its walls, dismantle the masonry, and then, after installing the liner, return the brick to its place and finish it. This process will not only take quite a lot of time, but will also require certain costs. In addition, such large-scale construction work will not happen without a lot of dust and dirt. And this, to a certain extent, paralyzes normal life in the house, and has a very unfavorable effect on the decoration of the entire room where the stove is installed.

No matter how well the brickwork is made, it is impossible to make its inner walls perfectly smooth - it’s just that the surface of the brick itself is rough. And plus, the seams between the bricks and the influx of hardened mortar also become obstacles to the exiting combustion products. Therefore, soot inevitably settles on surfaces in growing layers, which over time narrow the channel, reducing draft in the furnace.

Naturally, the chimney must be cleaned periodically. However, both the mechanical impact from cleaning and the aggressive influence of combustion products and high temperatures lead to the destruction of the bricks themselves. Plus, the solution between them loses strength and crumbles. But this leads to a violation of the strength of the brick chimney itself, making it unsafe. This includes the likelihood of carbon monoxide poisoning of the residents of the house and the risk of a fire hazard. A timely installed tab will help keep the chimney ducts intact and prevent possible accidents.

The sleeves have perfectly smooth walls. In addition, in lifting areas they are never installed with right angle turns. All this allows smoke, along with solid particles of combustion products, to freely leave the internal space of the channel without encountering resistance.

Naturally, the earbuds can also become unusable over time. But it will be easier to replace this element than to make repairs or completely re-lay the chimney or even the entire stove.

When does sleeving become an urgent necessity?

So, the following moments may arise when there is an urgent need to install a liner in the chimney duct of the stove:

- If the design or installation of the chimney is carried out with errors, as a result of which backdraft constantly occurs during the fire.

- If the fireplace or stove is the main source of heating and is used continuously throughout the heating season.

- If the smoke exhaust duct is long.

- If the stove design initially includes a lined chimney.

- If a significant part of the chimney duct passes through an uninsulated attic or above the roof.

- If a brick chimney is built into the external wall of the house or runs from its outside.

- If, when cleaning a brick channel from carbon deposits, abundant condensate leaks are found.

- If the stove has been in use for a long time, and the chimney needs not only cleaning, but also repair, there are signs of destruction of the brickwork, and depressurization is felt.

- If the chimney duct becomes clogged too often and requires several cleanings during the heating season.

Any of the listed signs should make the owners of the house think about the need for glazing.

What are the advantages of chimney lining?

Many people wonder whether it is worth lining a chimney at all, incurring additional costs? To get an answer to this, it makes sense to highlight the advantages of having such a pipe upgrade:

- If the liners are installed immediately during the construction of the furnace, then in the future you will not have to disassemble and reassemble part of the structure to perform liners, the need for which, one way or another, will arise.

- If there is a tab in the chimney, in case of an emergency it is much easier to replace it than to completely relay the chimney duct.

- If the chimney of an operating stove needs repair, then lining is faster and easier than dismantling and erecting a new chimney. Do not forget that its construction will entail complex processes of sealing penetrations through the floors and roof, while installing a liner will help to avoid this stage of work.

- The sleeve reliably protects the brickwork from exposure to high temperatures and the aggressive chemical environment of combustion products.

- Installing a liner will help you quickly and relatively inexpensively correct errors made during the construction of the chimney or get rid of problems that arose during the operation of the stove.

- The most important advantage is the reduction in the risk of a fire hazard when the tab is depressurized. If for some reason the liner is damaged, the combustion products will still leave the furnace, but through the main brick pipe. Naturally, this gives time to organize repairs.

- Soot deposits do not accumulate on the smooth walls of the liner for a long time. And when they appear, cleaning the pipe is much easier than tidying up the brickwork.

- The presence of a sleeve significantly extends the life of trouble-free operation of not only the smoke exhaust duct, but also the entire heating structure.

It must be assumed that the listed arguments should be enough to convince stove owners of the usefulness of sleeves.

Types of liners used

The principle of placing sleeves in the chimney is the same. But the liners themselves may differ in the material they are made of, so the installation process of each type has its own nuances. Today, specialized stores offer sleeves made of stainless steel, special heat-resistant polymers, asbestos cement, and ceramics.

Stainless steel sleeves

Sleeves made of stainless steel have very good durability, as they are highly resistant to high temperatures and the corrosive effects of combustion products and condensate. A wide range of liners made from this material is designed for chimneys of various configurations, lengths and cross-sections - you can choose the right model for specific initial conditions.

- Round pipes with a diameter of 60 to 1000 mm, made of sheet metal. The thickness of the steel from which the products are made can vary within 0.5÷1.5 mm. For complex shapes of chimney channels that have turns located at different angles, manufacturers have provided the necessary transition parts, which are selected individually in each specific case. However, to select them, you should know in advance the exact detailed diagram of the chimney system.

- Inserts with a square or rectangular section are rarely used, since they are very inconvenient to work with. They are only suitable for chimneys or ventilation ducts that have a smooth channel without changing direction. The most common size of rectangular liners is 140x270 mm.

- Stainless steel liners with an elliptical cross-section are often used for chimneys with a rectangular cross-section. They are made of metal with a thickness of 0.5÷0.6 mm. The most popular sizes of these products are 200×100 and 240×120 mm. In terms of throughput, this approximately corresponds to round pipes with a diameter of 150 and 200 mm, respectively.

- Corrugated insert-sleeves, made of various grades of stainless steel, the walls of which consist of two layers. This type of pipe is good because it can be used for chimneys with a complex configuration, that is, with the presence of turns and bends, as it has good flexibility. In this case, the insert does not require additional connecting elements, which means that the risk of depressurization of the chimney system at the joints of individual sections of the pipe is eliminated.

However, when choosing this type of liner, you should remember that there is also a limitation - it is not recommended to use a corrugated insert with a diameter that will reduce the cross-section of the chimney by half or more.

Prices for stainless steel sleeves

Chimneys

Corrugated stainless steel inserts are available with diameters from 80 to 350 mm.

Although the flexibility of the corrugated sleeve allows it to be used in any type of chimney, and it has no joints, this option is not considered durable and reliable for constantly used heating devices. Practice has already proven that, despite two layers of metal, a pipe can burn out in literally 4–5 years. And the corrugation ribs themselves become a “trap” for soot deposits to settle on them.

Ceramic chimney liners

Sleeves made of ceramics are considered the most durable and reliable. Therefore, they are most often used to restore damaged chimneys. Like stainless steel liners, ceramic liners come in a variety of shapes and sizes—they come in round, elliptical, rectangular, or square with rounded internal corners. The connection of individual sections of the tab is carried out using a tongue-and-groove lock or in a socket.

The ceramic version of the liners is used for straight chimneys, since the range of rotary modules for this type of liner is very small. Therefore, if necessary, ceramics are combined with parts made from other materials, selecting them according to shape and size.

Ceramic modules are produced in heights of 330, 660 and 1330 mm. The wall thickness of the liners ranges from 4 to 20 mm. The diameter of round liner models can vary from 120 to 450 mm.

Prices for ceramic liners

Ceramic pipe

Ceramic sleeves have perfectly smooth inner walls, while the outer walls may have minor defects in the form of roughness or small depressions. But this does not in any way affect the quality of the chimney as such.

If we highlight the advantages and disadvantages of ceramic liners-inlays, then their main performance characteristics immediately appear.

The advantages of ceramic inlays include the following qualities of such products:

- Large heat capacity and the ability to accumulate heat.

- Excellent resistance to high temperatures. Ceramic sleeves can withstand heating up to 1400 degrees, without any damage or changes in the structure of the material.

- The material is resistant to open flames, so it is not afraid of possible fires of soot deposits.

- Ceramic products are inert to corrosion processes and the effects of aggressive acids.

- The smoothness of the internal surfaces virtually eliminates the occurrence of turbulence when combustion products exit. That is why a minimal amount of soot settles on such material.

- Thanks to all these listed qualities, ceramic liners have an enviable durability in use.

However, we should not forget that this material also has its negative qualities:

- Ceramic modules have a fairly large mass, which complicates both their transportation and installation work.

- The material is hygroscopic, that is, it is able to absorb moisture.

- Fragility of the material. The modules do not withstand external mechanical influences, that is, special care is required during their transportation and installation.

- It takes a certain amount of time to warm up the ceramics.

- To correctly install ceramic blocks in the chimney duct, you must have certain skills. Therefore, to carry out the work you will have to invite a specialist, whose services are not cheap. Add to this the considerable cost of the products themselves.

- When installing a ceramic insert into an already built chimney, you will have to dismantle the wall of the chimney shaft. There are simply no other options.

Ceramic inlays are great for brick chimneys, fireplaces, and sauna stoves. They have also proven themselves well in pipes connected to solid fuel heating boilers.

Asbestos cement tabs

Asbestos-cement pipes, in fact, are not intended for arranging a chimney or as an insert in a brick chimney of a stove, fireplace or boiler. Despite this, they are actively used for these similar purposes. And also for extending the chimney or ventilation duct.

Asbestos in such products serves as a reinforcing material, since it is a fiber. And the main binding substance is cement, which provides rigidity and strength to the products.

Fire safety is one of the determining qualities of a material when choosing chimney liners. Therefore, it is imperative to take into account that asbestos-cement pipes are capable of operating at temperatures not exceeding 300 degrees. At higher temperatures, such a pipe can easily crack. That is why this option is suitable only for the upper part of the pipe, since heated gases, reaching this area of the chimney, cool to non-hazardous temperatures.

In addition, with some reservations, pipes made of this material are suitable for gas heating appliances with low power.

Lengthening the height of the chimney using an asbestos-cement pipe is carried out in cases where there is insufficient draft in the furnace, and the formation of condensate in the shaft increases noticeably.

Some home owners, seduced by the availability of the material, still install asbestos-cement pipes as a liner. To prevent a wrong choice, it is worth explaining how this material usually reacts to the aggressive effects of combustion products.

Asbestos cement has a porous structure. Therefore, both smoke and vapors will easily penetrate into its thickness. Due to the fact that the material has low thermal insulation abilities, condensation occurs when hot gases collide with low temperatures. When condensate is mixed with soot, oxides are formed, which also penetrate the pores of asbestos concrete, slowly corroding the pipe walls.

Therefore, shells appear on the internal surfaces, in which soot settles more actively, narrowing the internal diameter. As a result of these negative processes, traction deteriorates and the efficiency of the heating device decreases, since the fuel does not burn completely.

You might be interested in learning why

Prices for asbestos-cement pipes

Asbestos-cement pipe

Taking into account all the processes listed above, we can expect that replacing an asbestos-cement pipe with a new sleeve will be required within 10-15 years. For such a design, the period is clearly insufficient.

In addition, it is always necessary to remember the dangers of asbestos to human health. It is for this reason that EU countries have completely abandoned products containing this substance. Russian manufacturers claim that they use chrysotile asbestos in their products, which has lower toxicity compared to its European counterpart. However, given the conditions in which the material will be used, it is still not worth the risk. Moreover, there are other options with more suitable characteristics.

Conclusion - you should think very carefully before using asbestos-cement pipes to line a chimney. Although many home owners still choose such products because of their low price, turning a blind eye to all the negative aspects of the issue.

Polymer sleeve "Fitfire"

The polymer sleeve is not yet as popular among Russians as the above materials. Perhaps because its cost is quite high, and some - simply due to the lack of necessary information.

But it is worth recognizing that the results that this method of lining a chimney shows in practice fully justify the considerable cost of the sleeve itself and the work on its installation.

“Fitfire” is an inlay produced in the form of a sleeve consisting of several layers. The maximum length of the polymer sleeve is 60 m, the diameter after final installation is from 80 to 500 mm, and the service life of this material, declared by the manufacturer, is at least 50 years.

Sleeves are produced in several types. Thus, for low-temperature and high-temperature heating devices, the composition of the polymer used in the manufacture of the insert differs. The purpose of the liner is indicated in the material labeling. For example, the Fitfire sleeve is used for chimneys to which low-temperature boilers are connected. Well, “Fitfire NT 1000” is installed in the pipes of stoves and fireplaces.

It should also be noted here that the hose is used for sanitizing chimneys built from different materials - brick, metal or concrete.

The sleeve consists of three layers:

- The inner layer is made of modified polyethylene, designed for use at high temperatures.

- The middle layer of the sleeve is a fiberglass mesh impregnated with a polymer resin that hardens when exposed to high temperatures.

- The outer layer consists of a special protective dense but elastic material that can withstand significant stretching.

Using a polymer sleeve to rehabilitate a chimney allows you to obtain a protective channel completely without joints. In this case, there is no need to dismantle the brick shaft.

The polymer sleeve has excellent flexibility, so it can be easily laid in turns of up to 30 degrees in difficult areas of chimney ducts.

The material, unlike metal and asbestos cement, is resistant to aggressive condensate components, which is why its service life is longer compared to other inlays.

The process of lining a chimney using Fitfire will take no more than 5–6 hours in total. When carrying out work, the hose is passed through a pipe shaft that has been previously cleared of soot deposits. In this case, a reserve of 300÷400 mm is left in the upper part of the chimney.

Then, special equipment is connected to the lower end of the sleeve, which fills the inner space of the sleeve with hot steam. In this case, the material softens under the influence of temperature, the sleeve swells, distributing along the walls of the main chimney. When cooled, the polymers harden, maintaining their adopted shape.

Some Russian craftsmen have gotten used to doing without special equipment. By installing the hose in the chimney and expanding its lower edge using a metal pipe, the stove is heated. At the same time, flows of hot combustion products and air act on the material of the hose, expanding and pressing it against the walls of the main chimney. However, in order to obtain high-quality lining of the shaft, it is recommended to entrust this work to specialists who, with knowledge of the matter and compliance with technology, will install the liner.

So, a flexible polymer hose can solve several problems at once in protecting the main chimney channel:

- The acquired smooth surface does not retain condensation, which immediately rolls down.

- Soot deposits do not collect in the rounded corners, so normal draft is maintained in the furnace.

- There are no pores on the inner layer of the sleeve, so it does not absorb moisture and combustion products.

- The material is resistant to the aggressive effects of acids formed during the interaction of combustion products and condensate. Therefore, it is not damaged or destroyed during operation of the heating device.

Based on the above, lining the chimney with a Fitfire polymer sleeve can be called the most effective and reliable option today.

Two factors stand out among the disadvantages of this sanitization method. Firstly, the high cost of the material itself and its installation. And secondly, the need to attract a professional team with special equipment.

However, with any chosen method of sleeving, it is better for an inexperienced person not to undertake such a task. The risk of a poor-quality result is too great, and the stakes are too high - you can completely ruin the existing chimney.

Video: The process of lining a brick chimney with a liner"Fitfire"

Installation work on chimney lining

The most complex and time-consuming option for rehabilitating a chimney is to install liners made of metal or ceramic into the finished chimney of a heating appliance in use. This is due to the fact that part of the structure has to be dismantled.

Preparatory work

Whatever lining method is chosen, before installing the tab, it is necessary to carry out preparatory work, which includes the following activities:

- If you plan to renovate a chimney connected to a heating boiler, then before starting preparatory work, the device should be covered with plastic wrap. Otherwise, dirt and soot deposits may get inside the boiler and damage its normal operation. And the floors in the room where the boiler is located should also be protected from contamination - everyone knows how difficult it is to wash off greasy soot stains.

- The second step is to inspect the chimney shaft. For this purpose you will need a powerful flashlight; it is often difficult to do without a mirror. When carrying out this procedure, the degree of contamination and destruction of the channel walls, the presence of protruding bricks and mortar deposits are determined.

- Next, the pipe must be cleaned of accumulated layers of soot. This process will require special brushes and scrapers. Brushes are capable of cleaning the walls from soot deposits, and scrapers are required to remove resinous deposits.

- Bricks protruding from the masonry will interfere with the installation of the sleeve, especially if a metal or ceramic inlay is selected. Therefore, later, when part of the chimney wall is dismantled, the bricks must be carefully knocked down to the level of the main surface of the channel walls, and the mortar flows must be knocked down completely.

- After cleaning, it is necessary to measure the length of the chimney channel and its internal cross-section. The obtained parameters must be transferred to the diagram being compiled. It should also display all available turns with the magnitude of their angle. This is also especially important when choosing inlays made of hard material.

- The next step, in the case of installing flexible inlay options, is to disassemble only that part of the chimney that is adjacent to the stove. A shaped structural element will be embedded in this area. If the insert is made of ceramic or metal, and the chimney has complex turns, then you will have to dismantle part of one of its walls.

- Next, the bottom of the shaft channel must be cleared of any debris that has fallen on it when cleaning the pipe. If necessary, the bottom of the shaft is leveled.

- After all the parameters and configuration of the chimney have been determined, based on the drawn up diagram, all the necessary structural elements are acquired.

Scheme and process of installing a steel liner in the chimney shaft

To understand all the nuances of installation, it is first worth considering a diagram in which not only the details of the tab are clearly visible, but also their location in the structure.

So, it would be correct to start considering the installation exactly in the order in which it is carried out in practice when installing the sleeve. The table below provides illustrations and a brief description of the process steps. In this case, you should focus on the assembly diagram:

| Illustration | Brief description of the operations performed |

|---|---|

| When describing the preparatory work, it was said that the bottom of the brick shaft is leveled with concrete mortar. This can be done if its bottom is at the required level for connecting the heating device. If the bottom of the insert should be higher, then a metal cantilever stand is used to install it, fixed inside the shaft to its walls. It can be seen in the diagram. |

| A tee is installed on the stand or at the bottom of the shaft, in the lower part of which there should be a threaded pipe and a plug for connecting a condensate drain pipe. The tube can be installed permanently or connected as needed. Depending on how you plan to secure the tee, the pipe may be located at the bottom or front of the tee. |

| In addition, the tee must provide for the possibility of inspection, as well as cleaning the bottom part of this structural part. This could be a door or a lid. If the inspection hole is closed with a lid, then a threaded pipe for condensate drainage may be located on it. |

| This photo shows how the outlet pipe is connected to the tee branch pipe. Naturally, this process is carried out after the liner is installed in the chimney shaft. The tube will then be diverted to an accessible and convenient place for discharging the condensate. |

| Next, when the direction of the pipe is determined by the tee, markings are made inside the shaft to secure the brackets. They must be calculated so that they do not fall on the joints of individual pipe sections. When installing the brackets, it is recommended to cover the hole in the tee pipe so that dust and small fragments of brick do not get inside this part. |

| The next step is to install pipe sections into the open part of the shaft and join them together. After installation, they are fixed to the wall with brackets. |

| The brackets can have different designs and be attached to the rear or side wall of the shaft, at a distance from each other of approximately 1000÷1200 mm. In some cases, for example, when the sleeve fits tightly into a niche and has a sufficiently large diameter, that is, it stands firmly on the base, then the craftsmen do without these fasteners altogether. |

| Individual sections of pipes are connected to each other using a socket joint. To prevent gases from escaping outward, it makes sense to use heat-resistant sealant on the connecting nodes. |

| It is very important to accurately calculate and install the pipe section so that when connecting the boiler you do not have to use complex connections. To make it more convenient to join the lower part of the tab, installed on the bottom of the shaft, and the upper part, lowered through the chimney pipe, there should be a free area with a height of 400÷500 mm between the lower section and the top of the niche. |

| When the lower part is mounted, the upper part of the sleeve is installed through the chimney pipe as a single assembled unit. Installation through the chimney must be done very carefully so as not to damage the sleeve due to possible unevenness of the walls of the shaft. |

| This illustration shows the chimney shaft before and after installing the liner for comparison. After the upper part of the liner passes the entire channel and appears in the niche, it is joined to the lower section of the sleeve. |

| If you plan to slightly increase the length due to the liner, or attach a head with a protective roof to it, then special structural elements are used for this. |

| This is a piece of pipe that can have different heights, depending on the result you want to achieve. It is located on a platform mounted on metal profiles designed to fix this element on a brick chimney. At the same time, it must be secured to the upper end of the sleeve mounted in the chimney shaft - this must be provided for when installing it. That is, if it is planned to extend the pipe, then the insert should protrude above the brick surface to the height of the socket joint. |

| Having securely connected this extension part of the sleeve, a head with a protective umbrella is put on top of it. The umbrella must completely cover the brick pipe so that moisture cannot penetrate through possible gaps between the brick and metal walls. |

| Heads can have different designs and perform several functions. For example, a head with a deflector can not only protect the chimney from moisture, but also regulate the draft inside the system. In addition, if a brick chimney has a large perimeter, it means that an additional “roof” must be installed above it, and the head is passed through it and fixed on its surface. |

| Next, the mounted metal tab is connected to a boiler or fireplace installed in a permanent place. The configuration of the location of the pipes can be different; it also needs to be thought out in advance and the necessary components purchased. The diagram shows a section of pipe with a damper, but it is necessary if it is not possible to adjust the draft using the heating device itself. |

| When the heater is connected to the sleeve, it is necessary to check its operation. To do this, turn on the boiler or, for example, light the fireplace. If the draft is good and the device is working normally, then you can begin to restore the wall of the chimney shaft. |

If a stainless steel or ceramic sleeve is installed in a chimney shaft that is quite long and has several turns, then the front wall of the shaft will have to be dismantled along its entire length, otherwise it will not be possible to install shaped connecting elements. You can open the shaft only in those places where the rotating parts of the structure will be located, but for this you need to have an accurate diagram of the passage of the chimney.

Features of installation of corrugated stainless steel hose

Installation of a corrugated hose can be carried out without dismantling the walls of the shaft, if it is thoroughly cleaned first. Moreover, this process can be carried out both with a straight chimney and with a small number of smooth (up to 30 degrees) turns.

It is important to correctly “tie” the upper and lower edges of such a sleeve. After the flexible hose is placed in the smoke exhaust duct shaft, its lower edge is securely connected to the rigid tee adapter. This element must also be made of stainless steel and have a condensate collector equipped with a pipe for draining it.

The upper section of the pipe should also be equipped with a rigid metal sleeve. To make it easier to attach this rigid section, an excess length of 250÷300 mm is left on the corrugated liner in the upper part. The connection between the corrugation and the rigid sleeve must be reliable, so to fix them together, in addition to the clamp, you should additionally use a heat-resistant sealant, for example.

* * * * * * *

The cost of chimney lining will depend on what material the liner is made of. Installation fees are calculated for each linear meter of liner. After the length of the shaft has been measured, it is necessary to find out the cost of installation in a particular region and the cost of the selected tab and all the elements necessary for installation. This data will help calculate the exact cost of both the material itself and its installation.

Evgeniy AfanasyevChief Editor

Author of the publication 08.09.2018

The quality of functionality of a brick chimney is directly related to the formation of soot on the walls of the smoke exhaust device. Under the influence of high temperatures, chemical elements formed as a result of combustion accumulate a layer of soot, especially in brick chimneys, the surface of which is rough and uneven, which in itself creates conditions for the accumulation of combustion products.

The result of this process is the formation of reverse draft, i.e. the pipe ceases to cope with its functions, and exhaust gases penetrate into the room rather than being discharged outside. This poses a threat to the life and health of people, so the condition of the chimney should be checked regularly, and measures should be taken for high-quality smoke removal.

To improve the functions of the chimney, you have to either completely relay the smoke shaft, or protect the walls by lining, that is, insert an additional pipe made of refractory material into the brick chimney.

And if the first option is an expensive undertaking that entails additional inconvenience, then reconstruction of the chimney is a more budget-friendly method that can be done on your own without the use of complex tools and devices.

The sleeve is a pipe made of refractory material with a perfectly smooth surface on which combustion products do not accumulate.

Due to the fact that the free space between the pipe and the sleeve is filled with insulation, this creates additional thermal insulation, therefore, the amount of condensate is reduced and heat transfer increases.

The sleeve can be freely removed and cleaned if necessary.

Note! The sleeve is often installed in a brick chimney even at the construction stage. This saves homeowners from problems with smoke removal in the future and greatly simplifies lining.

Types of chimney liners

Depending on the material from which the sleeve is made, there are:

- lining the chimney with liners made of refractory polymers;

- lining using steel pipes;

- using a corrugated stainless steel pipe as a sleeve.