Thermal insulation of frame buildings is very important, since heat must be retained inside the building. The technology involves the use of up to 75% insulation in the construction of walls. But this material loses its thermal insulation properties if moisture gets into it from the inside. To ensure the dryness of the entire building, a vapor barrier is used for the walls of the frame house.

What is the vapor barrier of a frame house?

This term means the use porous membranes, with the help of which excess moisture is removed from the inside and does not enter from the outside. Thus, the house can “breathe” and does not turn into a closed greenhouse. Partial air exchange is provided by wooden structures, which allow 35% of the air volume to pass through them.

Some people, when making a vapor barrier with their own hands, install ordinary plastic film instead of a porous membrane. This is wrong, as it begins to accumulate water and cause the wood to rot.

Unlike polyethylene, vapor barrier film has a more complex structure and consists of multiple porous layers. One side is smooth (it is adjacent to the insulation), the other is rough. This feature is needed for better collection of moisture and its further removal.

There are films in which both sides are the same, so they can be installed in any order. Before installation, it is better to read the instructions and find out what type of membrane you have.

There are also membranes with specific purposes. They are intended for vapor barriers only in specific conditions. For example, exclusively in non-residential premises, in harsh climates, with high humidity (baths, saunas).

What is the difference between vapor barrier for frame houses

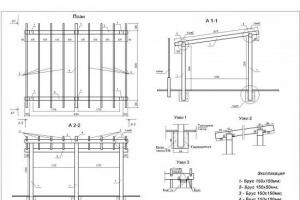

The vapor barrier of a frame house is carried out practically according to the same scheme as for other buildings, but there are also some differences. So, load-bearing structures do not have an insulation function, and this is a significant difference. The “pie” of the wall looks like this:

- External decorative finishing (siding, lining).

- Waterproofing film.

- Wooden frame.

- Thermal insulation layer.

- Vapor barrier film.

- Lathing.

- Interior finishing materials.

The vapor barrier material is quite easy to install. It is necessary to properly lay and secure it. To do this, you can use tape and galvanized nails or a construction stapler. But there are also some subtleties:

- seal all membrane ruptures with tape so that there are no gaps;

- minimize the number of folds;

- seal all seams properly and check for integrity;

- where the wood comes into contact with the vapor barrier, apply a special antiseptic;

- a diffusion membrane can be in direct contact with the insulation; for another type, you need to leave a gap of 5 cm;

- The sides of the membrane cannot be swapped, as it will lose its properties.

If you make a mistake somewhere and make a mistake, the vapor barrier of a frame house will be ineffective, and it will have to be changed along with replacing the insulation, which will cost a tidy sum. Very often, those who like to do everything with their own hands try to install the membrane faster, so they perform the installation sloppily. Because of this, the vapor barrier only lasts for 2-3 years, and then it has to be replaced.

As for the rules for laying the material, this must be done from top to bottom. There should be between layers overlap of at least 10 cm, glued with a special vapor barrier layer. You also need to carefully glue the places where the film is adjacent to the wood.

When a vapor barrier is not required

There are insulation materials that do not collapse, despite the lack of vapor barrier. Therefore, builders may not use it. But then another way to remove moisture from the room is needed.

Thus, polyurethane foam and polystyrene foam do not allow moisture to pass through, so it is necessary to install a forced air exhaust, otherwise moisture will accumulate in the room and contribute to the development of mold. Also, there is no need to carry out vapor barrier in houses without insulation.

Vapor barrier schemes in a frame building

Depending on the design of the house, different vapor barrier schemes may be used. Let's look at them below.

Double vapor barrier

In the case of double-sided wall decoration non-breathable materials(plastic, tile, oilcloth) water can collect inside, since there is nowhere for it to escape. To avoid this problem, a ventilation gap is provided between the cladding and the wall. It must ensure air circulation and release to the outside.

Elimination of excess moisture in a frame house is carried out in the following ways:

- The membrane is fixed to the frame posts, after which interior finishing work is done.

- A vapor barrier membrane is installed, then a sheathing is installed to secure the facing materials. This allows for a ventilation gap of about 5 cm.

The second option is best suited for residential buildings, since the likelihood of moisture accumulation inside the walls is higher there. And the construction of structures without a ventilation gap is permissible only in buildings for non-permanent use. There, as a rule, simple ventilation or a supply and exhaust system is installed to get rid of high humidity.

If the house is held high-quality ventilation system, the vapor barrier layer has virtually no beneficial effect. It is then needed only to prevent the possible accumulation of moisture inside the wall.

External building insulation and vapor barrier

As already mentioned, the vapor barrier layer should not be in direct contact with the wooden frame. Therefore, for the outside, first the wall is covered with wooden slats, the thickness of which is 25 mm. The distance between the slats is 1 m.

Next, a membrane is stuffed onto the slats rough side out, after which the sheathing is installed again. And only after that the house is insulated with heat-insulating materials, the waterproofing layer is fixed and the finishing is done on the outside.

Thanks to such a complex design, the vapor barrier of a frame house creates the necessary microclimate in the room.

As for the disadvantages of the technology, the structure will dry out for several years. In addition, all joints and grooves must be carefully sealed and treated with a sealing compound. An important requirement is the need to use exclusively hydrophobic materials for insulation.

Floor vapor barrier

The floor must be insulated and this must be done in parallel with steam and waterproofing. Firstly, moisture will constantly flow from the basement or basement. Secondly, indoor humidity can also damage the thermal insulation structure.

- Installed on the subfloor waterproofing layer. Tightness is ensured by overlapping the film and gluing the joints with tape for this material.

- Insulation in the form of rolls or slabs is laid between the floor joists, after which the entire structure is sheathed with a vapor barrier layer. It is also made one-piece by fastening the film overlapping with tape.

- In the logs, ventilation gaps are made between the vapor barrier layer and the floor using boards that are secured with self-tapping screws.

- At the final stage, a tongue-and-groove or edged floorboard is laid on top of all these structures, and a finishing coating is placed on top of it.

If you plan to make a vapor barrier for floors in a frame house, please note that it is only relevant if insulation that allows air vapor to pass through. Foam plastic does not allow air to pass through, so installing a membrane is irrelevant for it. It is best to choose mineral wool for floor insulation, the density of which is 37-57 kg/m3. m. It is very light and provides air exchange.

Ceiling insulation

Almost all ceilings of frame houses are insulated using mineral wool. Expanded clay, expanded polystyrene and ecowool are less commonly used.

Insulation is done like this:

- First, a vapor barrier membrane is secured to the bottom of the beams using a stapler, after which boards are stuffed onto it. The interval between them is 40 cm.

- Next, the entire ceiling is insulated with mineral wool. Important make overlaps on the walls so that there are no areas through which heat will escape. The seams should not be continuous, that is, the slabs are laid in a checkerboard pattern.

- If you plan to insulate the attic, line it with another vapor barrier layer. All film joints are sealed. If there is no heating in the attic of a frame house, this stage can be eliminated. Next, they lay out the floor in the attic.

If the ceiling is correctly assembled and insulated, moisture will not collect either from below or from above.

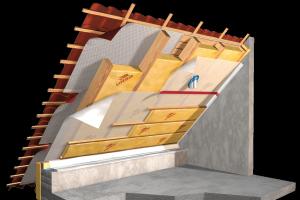

Proper roof insulation

The principle of insulating the roof of a frame house is similar to the rules for walls, with the exception of some features.

- A waterproofing layer is installed on top of the rafters, which is additionally secured with a lath on which the roofing material is supported. There is a large free space between the rafters themselves. Rigid insulation boards are laid there.

- A gap is made between the slabs and the waterproofing layer so that moisture can be removed and the structural element itself can be ventilated with air. On different sides of the house they draw conclusions from this gap.

- It is very important to maintain the tightness of the waterproofing. If the insulation comes into contact with water, it will quickly begin to deteriorate.

- The inside of the rafters is sheathed with a vapor barrier membrane, after which it is stuffed again lathing for installation of internal facing materials.

If the attic is properly insulated and insulated from excess moisture, you can even install heating there. This will make it a full-fledged living space, and not a collection point for unnecessary things.

So, it is important to select and install vapor barrier membranes correctly. This will allow them to fulfill their function - to prevent the insulation from coming into contact with water, and also to remove excess moisture from the room.

Watch a video in which professional builders talk about the technology of vapor barrier for a frame house.

What is a vapor barrier?

Vapor barrier- this is any film with low vapor permeability, which is installed in a frame house from the INSIDE in order to prevent steam from entering the insulation and keeping the latter from constantly getting wet.

Do not confuse it with waterproofing, which is installed outside and is needed to protect the wooden frame from moisture! Special membranes are used there.

Do you need a vapor barrier for a frame house?

Yes. The technology of frame house construction requires the presence of vapor barrier materials in the walls, floors and ceilings! We must create a complete vapor barrier circuit, which is why frame houses are often called “thermos houses.”

Why do you need a vapor barrier film:

- prevents the insulation from getting wet (does not allow moisture to reach it)

- stabilizes the climate in a frame house

For this, a special vapor barrier material is used; spunbond and other films are not suitable.

Which side should the vapor barrier be laid?

But you take a regular vapor barrier film, then you won’t need to look at either side. But if you have already taken a specialized vapor film, then look at the instructions. EVERYTHING is written there. Just don't be lazy or force the builders.

Apart from the manufacturer, no one knows how to properly install a vapor barrier from his production; each of them has its own notes. But it’s logical that the part with his brand should be inside and we could see it, they tried their best for us!

U Izospana-B it's simple. The surface is rough inside, moisture remains on it, the smooth side of this vapor film is placed against the insulation.

This is where the questions about how to install a vapor barrier end. You can go to the website of the manufacturer of the vapor barrier film and look at the exact information there, for example, on the Yutafol website (isospan does not have a normal website).

Vapor barrier for the walls of a frame house

Vapor barrier of floor and ceiling in a frame house

You can vapor barrier the floor with film (standard), but you can do it a little lighter - underlayment under the laminate + plywood or OSB on the floor gives a good result. Or even linoleum. The floor is not where most of the steam goes, because the steam mostly goes up!

The ceiling is more difficult. The ceiling needs to be vapor-insulated with film, because all the steam goes up. I have a text about what it looks like in my home - .

Vapor barrier for ceilings in a frame house

The ceiling between floors does NOT need to be vapor-insulated, since there is warm air both below and above. But the top floor is a different matter, we work there in the same way as with the ceiling.

FAQ. Frequently asked questions about vapor barrier of a frame house

Vapor barrier. Inside or outside?

Inside of course! Steam goes from heat to cold.

Which vapor barrier to choose for the walls of a frame house

For walls and in general, the best vapor barrier for a frame house is a regular polyethylene film 200 microns thick (not thinner).

But if you really want it, you can buy Izospan or Yutafol vapor barrier, but for me it’s a waste of money. Americans usually use polyethylene without any brands.

Is it possible to have a frame house without vapor barrier?

In some climates, such as southern ones, it is indeed possible to build frame houses without a vapor barrier film. But these options are individual and you need to very clearly calculate the pies and dew point. I wouldn't experiment like that

Is it necessary to glue the vapor barrier and how?

Yes! The film can be glued using either special butyl rubber tape or glue. This is the only correct way, you can’t not glue the vapor barrier.

How to make a vapor barrier on video:

In order to maximize the service life of a frame house, it is important to pay special attention to its vapor barrier during the construction stage. From this article you will learn what materials are best to use to avoid the unpleasant consequences of exposure to moisture, and you will also become familiar with the most common mistakes in the process of laying vapor barrier materials.

Choosing a material for vapor barrier

Let's look at specific examples of each material, its advantages and disadvantages.

Reinforced polyethylene

A well-known, but already rarely used material, which was previously used to create a vapor barrier in wooden houses. Today, its use practically does not give the desired effect and reliability.

Advantages:

Among the advantages, one can highlight only the affordable cost of the material.

Flaws:

- Maximum care when installing. Polyethylene should not be stretched or stretched in order to avoid its deformation and ruptures. In addition, if it is strongly stretched, it can easily lose its functionality and integrity during the annual temperature change.

- Often, improper use of film turns a frame house into a steam bath, does not allow the walls to “breathe” normally, and accumulates moist air inside the house, making living in it uncomfortable and unpleasant.

Various types of mastic

They are special mixtures that are applied to the floor and walls of the house before creating the exterior decoration. They allow you to create a reliable vapor barrier layer on the outside of the walls of a frame house. Bitumen-kukersol mastic is one of the most popular. Its application does not require the creation of wall sheathing. It can be applied in several layers, but each of them must dry thoroughly.

Advantages:

- They allow air to pass through well and allow the walls of a frame house to “breathe.”

- Affordable price.

- Wide range of mastics to choose from.

- Mastic reliably retains moisture and preserves the house frame and insulation from destruction.

Flaws:

- Maximum accuracy during the application process.

- Requires application to previously prepared walls with a cleaned surface.

- Apply a very thin layer, avoiding the appearance of uneven areas.

Ruberoid

This is a modern and affordable building material that allows you to create a reliable vapor barrier layer. Suitable for creating an external vapor barrier layer for the walls of a frame house. Requires preliminary lathing of bars around the perimeter of the entire wall no wider than 50 by 50 cm.

Advantages:

- Relatively low cost.

- Availability of material.

Flaws:

- Be careful when working to avoid uneven joints and poor-quality seams.

Of the above materials, the most unsuccessful and undesirable for vapor barrier of a frame house is polyethylene. It does not allow air to pass through and can turn your home into a real steam bag with high humidity. In winter it will be cold and damp, and in the warm season it will steam like in a bathhouse.

Vapor barrier films

The optimal material for creating a vapor barrier layer for the walls of a frame house. Due to their functional features they are also called vapor barrier membranes. They reliably protect the house from the penetration of unwanted moisture into the insulation and into the room itself, and also ensure comfortable living in a wooden building for many years.

Flaws:

The only drawback is the fairly high cost of this material, but it also fully pays off during the operation of the frame house, because you don’t need to worry about replacing the insulation, as well as about the destruction of the wooden frame of the entire house, because special membrane films will provide it with long-term maximum protection from moisture from the outside sides and a pair - from the inside.

Advantages:

Ondutis vapor barrier films have proven themselves to be excellent in the building materials market for paraisolating the walls of a frame house.

Installation of vapor barrier from outside

The most important feature of installing a vapor barrier from the outside is to avoid a common mistake when installing double insulation, which most often contributes to rotting of the frame and accumulation of moisture inside the insulation.

Stages of vapor barrier outside

- Laying is done between the insulation and the wall.

- It is especially important to ensure that there is a special air gap between them.

- Films with a special adhesive layer are placed with the inner surface side on the insulation. It is important to ensure that the windproof membrane remains on top.

The following films are suitable for vapor barrier on the street side: A100, A120, A120 Smart. They reliably protect the outer surface of the wall from moisture and wind, allow moisture to pass through and ensure a normal microclimate inside the frame house.

Installation of vapor barrier from the inside

Stages of vapor barrier from the inside

- Vapor barrier membranes are laid on top of the rest.

- You can attach it directly to a wooden frame, having previously treated it with an antiseptic.

- On partition walls, the material is applied on both sides with an obligatory overlap.

- The joints are additionally treated with sealed tape with moisture-resistant capabilities.

Even if it seems that the air inside the house is very dry, and even specially purchased air humidifiers, it still contains a large amount of moisture vapor. Before the advent of energy-saving materials in construction, no one paid attention to this. Modern thermal insulation materials based on mineral wool were ineffective and lost most of their heat-preserving qualities due to gradual wetting. Therefore, special films have appeared on sale, some of which are mounted only on the outside and are wind- and moisture-proof, while others are located from the inside, on the side of the room, and prevent the penetration of steam. This article will talk about proper vapor barrier at home.

Why do you need a vapor barrier in your home?

A house without the use of a vapor barrier can be if it is insulated with foam plastic, penoplex, or does not have a thermal insulation layer at all, for example, foam block and brick.

- But to save on heating costs and to improve the heat-saving characteristics of houses in modern construction, natural insulation materials made from cellulose (ecowool) or basalt wool are almost always used. But here we must remember about the constant moisture exchange that occurs in the living room.

- So, if the house is too humid, then water vapor will inevitably be absorbed by the walls and ceiling, and, conversely, if the air is too dry, this moisture will return to the rooms. From which it follows that if the insulation in the wall is not protected by a vapor barrier film, then moisture will accumulate in it, filling all the air cavities between the mineral wool fibers, thereby depriving it of all its thermal insulation characteristics.

Tip: the exception is internal partitions in the house. One of the most important factors in which mineral-based insulation absorbs steam is the temperature difference that occurs near the outer walls. In this case, condensation accumulates inside, which is most dangerous for the material. But in interior partitions there is no such effect, so they are not covered with vapor barrier material.

Those cases when installation of a vapor barrier is required

- When the walls bordering the street are insulated with mineral wool from the outside;

- if the “pie” of the wall consists of several layers, one of which is cotton insulation. In this case, the vapor barrier film is mounted on the inside. The most striking example of such a device is frame houses;

- when installing ventilated facades. Mineral insulation should be covered on the outside with a waterproof film, and on the inside with a vapor barrier film. The first will protect the thermal insulation from water and air flows, and the second from the interior from steam. A good example is a wooden house covered with siding or wooden clapboard.

Vapor barrier films are produced in several types and, according to their intended purpose, are divided into wall and roofing films:

- roof vapor barrier. It is attached to the living room side, protecting the thermal insulation from rising vapors. This is an important stage, since moisture evaporation rises with warm air and can get into the insulation. This threatens not only loss of heat, but also the formation of mold and mildew. It is needed only when arranging a used and heated attic. If the attic space is cold, then a vapor barrier is not done, limiting it to a windproof membrane under the roofing material itself, which protects it from the formation of condensation;

- vapor barrier of house walls. It must be carried out with special materials, which, on the one hand, should not allow steam to pass through to the insulation, and on the other hand, freely remove it outside if moisture somehow gets inside. This happens due to possible cracks or incorrectly made joints of rolled materials. It is better to choose special diffusion materials instead of the usual plastic films or glassine;

- vapor barrier between floors. This must also be done, as condensation may accumulate from rising vapors.

- floor vapor barrier. Necessary in rooms with high humidity or in houses where the floor is insulated with mineral wool. In this case, a waterproofing film is placed on the bottom side, and a vapor barrier is laid on top. A vapor barrier is also installed when concrete floor slabs are located directly above the ground.

If the question is whether a vapor barrier is needed in a wooden house, then you must again rely on the presence of insulation. If it is not there, and the wall of the house consists entirely of timber or logs, then there is no point in installing a vapor barrier film.

Types of vapor barrier materials

Until recently, the only vapor barrier material used in Russia was glassine. But with the development of technology, they gradually began to move away from it, preferring more durable and high-quality materials.

- Polyethylene films. They are best used for vapor barrier of ceilings in residential premises. Most often, interfloor ceilings are insulated with mineral wool, as it has better soundproofing properties. Polyethylene film will reliably protect it from even small amounts of moisture. On sale you can find ordinary materials, reinforced or with a foil layer.

- Polypropylene films. It is best used to insulate the ceiling in a residential attic. They are distinguished by increased strength to mechanical damage and resistance to UV radiation. Once it is installed, you can safely repair the roof without fear that moisture will seep into the house.

- Membrane. This popular and frequently used type of vapor barrier is produced in the form of a single-layer or multi-layer roll material. These nonwoven materials can be single-sided or double-sided, their location and functional features will depend on this. The use of inexpensive double-sided non-woven membranes is considered optimal.

- Breathable films or breathable membranes. They completely exclude the possibility of water vapor penetrating into the thermal insulation, but at the same time do not in any way prevent their escape from the inside. They allow you to save on living space, since their operation does not require a ventilation gap.

- Conventional vapor barrier film. Its function is to create a vapor barrier on the inside of the walls and roof. It protects the thermal insulation material from steam ingress from inside the heated room.

- Vapor barrier membrane with reflex coating. Capable of partially reflecting heat back into the room. This helps increase the thermal protection of the room and roof by up to 10%. Compared to standard analogues, they have greater vapor barrier characteristics, so it is advisable to use them in rooms with high humidity.

- Vapor barrier membrane with limited permeability. They have diffusion abilities that allow steam to be removed from rooms that are not used regularly. For example, it could be a garden house that is actively used in the summer, but can only be heated a few times in the winter.

- Vapor barrier with variable vapor barrier properties. Ideal for renovation work, as they can be mounted from the outside without dismantling the internal lining.

Manufacturers of vapor barrier films

TechnoNikol

This well-known company guarantees that its vapor barrier films will last for decades. There are 3 main types of these products on sale:

- vapor barrier film TechnoNikol. Used for interior work. A fairly versatile material that is suitable for insulating walls, ceilings and pitched attic roofs. The price of a roll is 1500 rubles;

- diffusion membrane films TechnoNikol, designed to isolate the under-roof insulation from the formation of condensation in it. It is a non-woven polymer fabric with protection on both sides made of polypropylene fabrics. Unlike conventional vapor barrier materials, this is a breathable film. The cost for a standard roll is about 3,200 rubles;

- non-perforated vapor barrier film TechnoNikol. Narrowly targeted material for roof vapor barrier. Protects against both water and dust. For maximum strength, it is reinforced with a special mesh fabric. Approximate cost 1200-1500 rubles/roll.

Izospan

This is a rare case when a domestic company presents high-quality, world-class material at an affordable price.

- Izospan S. This is a two-layer film that protects the insulation from inside the room. It can also be used as a roofing film on non-insulated roofs. One side of it has a roughness, the role of which is to retain excess moisture and then evaporate it. The second side is smooth, it is mounted on insulation.

- Izospan B. An analogue of the previous material, it is also chosen for vapor barrier of the walls of a frame or wooden house from the inside.

- IzospanD. This is the most universal vapor barrier film from the entire presented product line of the Izospan company. It has an anti-condensation coating that can protect mineral wool from both internal steam and external moisture and wind. Its strength is so high that it can be used as an independent roofing covering for 3 months, even in winter. When installing it on the walls from the outside, it is allowed to postpone the installation of the finishing cladding for up to 6 months. Roll price 2500 rub.

Installation of vapor barrier of walls in a wooden house

The technology for installing a vapor barrier involves attaching it to the inside of the house between the insulation and the sheathing, to which the facing material is mounted. If a modern membrane material is used, then its smooth side is placed close to the insulation. In this case, the vapor barrier will evenly distribute the flow of moist air, releasing it into the ventilation system.

The method of attaching the vapor barrier depends on the purpose of the room in the house. In lightly used or non-residential rooms where humidity is low, it is permissible to use a one-sided method of arranging a ventilation gap. In all other cases, professionals advise to provide double-sided ventilation, which is much more effective. Often the membrane manufacturer indicates on the packaging the recommended installation method.

Stages of work

- If the house is not new, but renovation work is being carried out, then first they dismantle all the cladding down to the wooden frame of the wall. If possible, inspect the insulation or wood for damage and repair it if necessary.

- Walls and thermal insulation must be thoroughly dried. It is advisable to carry out work in the warm season, since in winter frost can form, which, covered with a vapor barrier, will turn into a large amount of moisture over time.

- If the house is frame, then the membrane is rolled out along the length of the entire wall and cut off so that in the corners there is an overlap of 10-15 cm with the adjacent wall. It is attached in stages to each vertical board of the frame using a stapler. There should be no distortions, cracks or folds. Therefore, it is more convenient to do the work together. The tension should be so strong that the insulation in the wall is located tightly without falling out of the wall.

- On top, again with an overlap, the next layer of vapor barrier is rolled out and attached in a similar way. After which the joints are taped with tape. A frame of slats is placed on top, which tightly presses the vapor barrier and at the same time serves as a frame for the cladding. It consists of vertical slats that are attached to self-tapping screws in increments of 60 cm (the distance corresponds to the width of the insulation and the frame of the house walls). In addition, the film is also secured with slats around the perimeter of all door and window openings.

- If you are making a vapor barrier for a house made of timber, then first of all they fill the walls with a frame under the insulation and lay it tightly there. Further all work is carried out according to a similar scheme.

DIY ceiling vapor barrier in a house

Most often it is done if the interfloor ceiling is made of wooden logs and insulated with mineral or basalt wool. To perform this work you will need two people; it will be extremely difficult to do it alone.

- Before starting work, the ceiling must be disassembled and consist only of joists.

- Then, from below, that is, from the side of the living room, a vapor barrier is attached along the joists. This should be done along the longer side of the room so that as few joints as possible are formed.

- The required length is measured and cut on the floor and, with the prepared section, raised to the ceiling. It is convenient when 2 masters are located on opposite sides of the room. This allows you to correctly position the vapor barrier and ensure that it does not warp during fastening.

- For ease of work, at first you can simply “grab” it in several places (but do it firmly). And after making sure of its correct location, secure it thoroughly.

- This is how they go through the entire ceiling, not forgetting about the overlaps and their sizing.

- It is attached from below to the joists with wooden slats, regardless of what the ceiling covering will be.

Advice: the work is quite painstaking and it often happens when an accidental tear occurs in an already secured area. In this case, a patch is cut out of the membrane with an allowance of 10-15 cm at the edges. It is inserted into the resulting hole and glued along the edge with glue. This creates a fairly sealed layer. The top is additionally taped with tape.

- Having finished fastening the vapor barrier, insulation is placed in the resulting cells from the side of the second floor.

Mistakes when making vapor barriers in a frame house

- Poor quality installation. At first glance, it seems that it is simply impossible to make a mistake when attaching a vapor barrier film. What could be simpler than stretching it well, attaching it to the frame and gluing the joints. But precisely because of the apparent simplicity, some builders neglect accuracy during work. As a result, tears or folds are formed. But the worst mistake can be the incorrect placement of the membrane, or rather the wrong side, as a result of which it begins to work incorrectly. If all this has already been covered with interior decoration, then the consequences of such work can only be guessed after a couple of seasons, when the thermal insulation layer begins to work worse.

- Installation of vapor barrier film on the outside of the house. This gross mistake leads to the fact that steam, leaking from inside the house and passing through the insulation, rests against the vapor barrier and settles as condensation on it. In a very short period of time, the insulation becomes damp, unable to ventilate. For external protection, it is necessary to use exclusively windproof films that are capable of allowing excess moisture to pass through.

- Lack of vapor barrier in a frame house. There are a number of materials that allow the absence of a vapor barrier. This is polystyrene foam or extruded polystyrene foam. Most often it is made in houses made of sandwich panels. But, in order to remove excess moisture from the house, in this case it is necessary to install a high-quality forced ventilation system. When insulating with ecowool or mineral wool, a vapor barrier must be present in all cases.

- Double vapor barrier. It happens when a vapor barrier layer is installed in rooms with high humidity, and a facing material with low vapor-permeable properties, for example, plastic panels or tiles, is laid on top. It turns out that after passing through the grout seams or panel joints, steam gets between the vapor barrier and the tile, without the possibility of escaping outside. Therefore, for cladding in such rooms, it is recommended to make lathing on the wall that borders the street.

- Or simply abandon the vapor barrier in this place, but there will be a risk that, once it gets into the insulation, the steam will not have time to evaporate through the windproof membrane from the outside. This is only permissible for frame houses that are used as summer cottages.

Choosing a vapor barrier installation method. In total, there are 2 ways to use the vapor barrier. In the first case, the film is attached to the wall frame, and sheathing material (plasterboard, lining, etc.) is mounted on top of the same load-bearing wall boards. In the second option, the film is similarly nailed to the wall frame, but under the wall cladding material an additional frame is made of slats 2-3 cm thick. Which method is considered more correct?

- The first option has a right to exist, but only if the highest quality materials are used for finishing. Otherwise, the repair will quickly become unusable due to the lack of a ventilation gap. Or use this method when the building has an economic purpose and is not used year-round. But even here it is necessary to make ventilation wiring throughout the room.

- The second option with the installation of a ventilation fence is more acceptable for houses intended for permanent residence. This helps eliminate the risk of excess moisture forming in the air.

Vapor barrier of a frame house is an important stage for this type of building. The vapor barrier is responsible for thermal insulation and the safety of the wooden frame.

Installed vapor barrier in the interior of the frame

Installed vapor barrier in the interior of the frame This is a film membrane that prevents moisture from entering the inner layers of insulation, where it can accumulate.

The frame consists of the following elements:

Air contains a certain percentage of vapor. Normal humidity in warm weather is from 30 to 60%, in cold weather from 30 to 45%.

Drawing of vapor barrier and interior decoration

Drawing of vapor barrier and interior decoration The level of moisture content depends on the type of room. In the bathroom and kitchen it is higher due to the vapors generated when bathing and cooking. Moisture moves, penetrates into the smallest micropores, into the thickness of walls, ceilings, and floors. The higher its concentration in the air, the more intense the process.

The second point that affects the humidity of walls and ceilings is the difference in temperatures outside and inside the room.

Installation of insulating material outside the frame

When cold air flows into the walls from outside in winter, it meets warm air coming from inside the room. When they come into contact, condensation forms - a “dew point”.

Increased humidity in the wall provokes the following consequences:

- The insulation, accumulating moisture, changes its geometry and does not retain heat well. Mineral wool is most susceptible to change.

- The concentration of moisture provokes the appearance of mold.

- Frame houses without vapor barrier are destroyed; it is necessary to ensure the escape of air vapors.

A vapor barrier for the walls of a frame house, complete with a superdiffusion membrane (wind protection), is necessary to regulate humidity in order to protect the insulation from the penetration of vapors into it.

A film, foil membrane installed on top of the insulation, from the inside of the wall, completely or partially prevents the accumulation of moisture in the inner layers. The superdiffusion membrane, which, on the contrary, allows steam to pass through, serves to remove them. It is installed after the main outer layer of walls, roofs, and ceilings.

Installation of a superdiffusion membrane on the walls of a building

Installation of a superdiffusion membrane on the walls of a building Vapor barrier for a frame house works in combination with, preferably forced. According to Western standards, a recuperator must be installed in frame-type buildings. The circulation of air masses reduces the concentration of vapors and prevents their stagnation.

How to choose material

To know which vapor barrier to choose for, you need to study the main types of vapor barriers.

Sectional structure of a frame wall

Sectional structure of a frame wall All materials are divided into film and membrane. The main difference is that a ventilation gap made of slats is required between the film and the finishing layer. It allows accumulated moisture to gradually evaporate. According to the technology, the membranes are installed on.

Among them are vapor barriers:

With absolute vapor barrier

The film does not allow vapors to pass through at all. These can be single-layer polyethylene films and foil material. This vapor barrier material is best used in rooms with high humidity and a moisture-proof finish.

For example, in a tiled bathroom, for interior internal partitions, since they are located in a zone of stable temperature conditions.

Foil membranes

A good material for wet rooms, baths, saunas is a foil vapor barrier. It prevents moisture from penetrating into the walls.

The process of attaching a foil membrane to the ceiling

The process of attaching a foil membrane to the ceiling The aluminum coating repels thermal radiation, preserving it. The price of materials varies; a foil vapor barrier is several times more expensive than polyethylene film. Installing a vapor barrier with absolute impermeability requires good ventilation in the room, since moisture will first accumulate on the finishing surface.

Scheme of ventilation device in a frame structure

Scheme of ventilation device in a frame structure If it does not evaporate, then through the seams, micropores will begin to penetrate and accumulate between the film and the finish, which will lead to peeling of the finishing material.

Vapor barrier with limited permeability

Materials that partially retain and transmit moisture are mostly represented by two-layer membranes.

Materials with variable vapor conductivity

Using this technology, vapor barrier roll materials with variable conductivity are produced. When the air is dry, they do not allow steam to pass through. With increased moisture concentration, micropores open, which partially allow moisture to pass through. These include reinforced film membranes. This is reliable material.

This is what a rolled vapor barrier looks like

This is what a rolled vapor barrier looks like The vapor barrier must be installed in conjunction with a windproof membrane that removes condensation. If vapors have penetrated inside, they must find a way out, so install a diffuse membrane in front of the outer layer.

Choose good, albeit more expensive, materials as a vapor barrier.

The short service life of cheap materials, usually labeled class “B”, leads to early destruction of the film. From interaction with oxygen to disruption of the integrity of the barrier that prevents moisture penetration.

Technical characteristics of various vapor barrier films

Technical characteristics of various vapor barrier films How to lay a vapor barrier

The film vapor barrier has a layered structure: on the one hand, a smooth surface, on the other, a rough surface.

All membranes are laid only from the inside of the house on the insulation, with the smooth side. The rough side retains condensation and it gradually evaporates.

Installation and installation of a vapor barrier is a simple process, but it requires care and careful sealing of all seams and joints. Membranes are laid over the entire surface of the room: on walls, ceilings, ceilings, roof.

The process of attaching material to the ceiling in a frame building

The process of attaching material to the ceiling in a frame building Vapor barrier of walls

The choice of material depends on the degree of humidity in the room. For fastening, construction staples are used, which are shot with a stapler. An overlapping vapor barrier is made at the joints.

Installation sequence:

A vapor barrier made using this technology will provide a reliable barrier.

Vapor barrier of partitions

For internal partitions, a vapor barrier may not be required. It is necessary in the walls of rooms with high humidity. It is better to install it on one side. The type of membrane depends on the finishing material inside the wet room.

To isolate the room from dust during the technical shrinkage of the insulation, in dry rooms, diffuse membranes (waterproofing) are laid on both sides of it.

Vapor barrier of interfloor ceilings

Installation of vapor barrier of the floor in a frame house and partitions is done in the following sequence:

Sequence of laying materials for floor insulation and vapor barrier

Sequence of laying materials for floor insulation and vapor barrier

The choice of para-insulating material depends on the place of its application. It is better to use thicker reinforced insulation in the floor. A thinner layer can be laid in interfloor slabs, which is cheaper. You can install the vapor barrier yourself, so you can be sure that it is installed securely.

Floor design option in a frame cottage

Floor design option in a frame cottage