The type of base for the fence is chosen depending on the type of soil and materials used in construction. A strip foundation for a fence is the best option, regardless of what the enclosing structure will be built from. To save money, you can build a base on brick pillars for a lightweight fence. The most expensive and labor-intensive is the installation of a stone foundation.

Choosing a foundation

Several types of foundations are used to install fences. The reliability and durability of the entire structure will depend on the correctness of the calculations and compliance with the base installation technology.

Before making a choice, you need to pay attention to the following parameters:

- type of soil and the degree of its shrinkage during seasonal fluctuations in temperature and humidity;

- the weight of the fence is important if the soil is weak and the structure can sag if the foundation is not laid correctly;

- the proximity of underground sources and the possibility of undermining the foundation under the fence with sewage, rain, and groundwater;

- when building near a highway or railway, vibration loads must be taken into account;

- Tall structures can tilt and bend in strong winds.

The foundation takes on the load and distributes it evenly onto the ground, thereby protecting the structure from shrinkage. A fence made of corrugated board and brick with a foundation will last much longer than without it.

Kinds

The main types of bases and their characteristics are presented in the table:

| № | View | Characteristic |

|---|---|---|

| 1 | Strip foundation for a fence | Used for constructing heavy fences made of concrete blocks, bricks, etc. Mounted in the form of a concrete strip around the entire perimeter. The width should be slightly wider than the fence itself. Depth varies from 500 to 800 mm. On construction sites with a slope, a belt with steps is installed at the places where the load-bearing supports are installed. |

| 2 | Columnar | It is mounted only under supporting elements to a depth below the freezing point of the soil. Such a foundation is suitable for a fence made of corrugated sheets, mesh and other lightweight materials. They drill holes at a distance of 2-3 m from each other, insert a pipe, reinforce it and fill it with cement mortar. |

| 3 | Combined | Used on difficult soils and for heavy structures. It combines a strip base that expands where the pillars are installed. |

| 4 | Stone | They are made of natural stone and brick and do not require reinforcement with metal reinforcing elements. Suitable for constructing fences made of stone or concrete slabs. |

The best option is a strip foundation for a fence with brick pillars. It is durable, reliable and beautiful.

Tape base

A strip foundation for building a fence made of corrugated board, wood, brick, stone is installed along the entire length of the fence.

Strip foundation for a fence

Strip foundation for a fence Calculation of parameters

Perform calculations of the main indicators:

- The depth of the foundation for the fence of strips made of lightweight materials is 500 mm. For fences made of heavy materials, soil characteristics and operating conditions are taken into account. Sometimes it is necessary to deepen the foundation below the freezing point of the soil, by 40 cm.

- The area of the base affects the resistance to wind loads. Correctly calculated indicators will protect the structure from shrinkage and give it strength. On heaving soil, incorrect calculation can lead to the soil pushing the structure outward.

The foundation area must be no less than (k(n)*F) / (k(c)*R), where:

- k(n) - reliability coefficient;

- k(c) - operating conditions coefficient;

- R - soil resistance.

All indicators of building materials and soil are taken into account when calculating the foundation.

Preparatory work

Before making the foundation for the fence, you need to do the following preparatory work:

- Clean the surface of debris.

- They make markings, drive stakes along the marked line and pull a rope between them.

- They dig a ditch to a foundation depth for the fence of at least 400 mm and a width of 400 mm. Where the supporting pillars are located, they are deepened by 60-90 cm, depending on the type of soil.

- Support columns with a height of 2500 mm and a diameter of 50 to 80 mm are selected.

- A layer of sand and gravel 150 mm thick is poured onto the bottom of the trench. Moisten with water and compact in layers.

The foundation for a fence made of corrugated sheets is made wider for better resistance to wind loads.

Is formwork necessary?

There are two options for installing a fence with a strip foundation:

Construction of a strip foundation for a fence

Construction of a strip foundation for a fence - Without formwork. In this case, the pillars are installed and secured in the trench before filling with cement mortar. They drill deeper holes under the pillars, insert a support and fill it with dense stones: gravel, pebbles. After this, the reinforcement is laid.

- Formwork is made from boards, plywood and other available materials. The boards are knocked down into panels equal in height to the foundation. The formwork prevents the trench from being covered with earth. They are installed in a ditch, spacers and supports are placed so that the structure does not fall apart under the pressure of concrete. Secure the supports. The foundation for the fence is reinforced with metal rods connected to each other by wire into a mesh structure.

The concrete shape helps ensure that the base is even and the fence will look more beautiful.

Pouring concrete

You can pour the foundation for a fence with your own hands:

- with technological breaks;

- in one go.

If the first option is chosen, you need to take into account that the time interval between pouring layers cannot exceed 12 hours. Otherwise, the strength of the structure will decrease.

When installing in one go, you will need a large volume of concrete mixture, which is better to order from a factory.

After disassembling the form from the boards, fill the gap between the foundation and the pit with sand or clay. They are compacted well, pre-wetting them. A strip foundation is most suitable for installing a fence made of corrugated sheets, bricks, or concrete blocks.

The formwork is dismantled after the concrete has gained more than 70% strength.

Foundation for a brick fence

Brick fence

Brick fence The foundation for a brick fence is installed taking into account the additional construction of brick pillars. Inside the brick pillar there must be a metal pillar, concreted with the lower end into the foundation.

Many people wonder how to make a high-quality foundation for a fence with brick pillars. The best option is to install a strip-column base. It has increased strength and has a beautiful appearance. Here is information on how to make a foundation for laying a brick fence with your own hands.

Installation technology

The foundation for a brick fence with your own hands includes the installation of a concrete strip with holes for installing posts. The width is calculated depending on the weight and height of the enclosing structure. The higher the fence, the wider the concrete strip should be.

The foundation for a fence with brick pillars is made with an expansion in depth; its shape should resemble a truncated pentahedron with a slight slope. The lower and upper ribs are arranged in a ratio of 1:2.

Preparatory work

Before pouring the foundation for a brick fence, you need to mark the area and dig a trench along the entire perimeter of the structure.

Step-by-step instruction:

- Marking is done by installing wooden or metal stakes, between which a rope is pulled level.

- Dig a trench about 500 mm deep and 400-600 mm wide.

- Make recesses under the pillars using a hand drill at a distance of 1-2.5 m from each other.

- Install the formwork according to the scheme described above.

- A sand cushion 150-200 mm thick is poured onto the bottom.

Lay a layer of roofing felt or other waterproofing material and begin installing supporting elements, without which the brick pillars will quickly become unusable.

Installation of supports

In order for brick pillars to serve for a long time, they must be properly strengthened from the inside:

Supports for a brick fence

Supports for a brick fence - Install metal supports, driving them to a depth of 200-300 mm. The width of the well should be 300 mm, the minimum depth is 1 m. On heaving soils, make a depth of at least 1200 mm. The supports are tied with metal rods and reinforced from the inside. Fill the cavity with concrete.

- For a fence made of brick pillars, reinforcement of the base along the entire perimeter is mandatory. Metal rods are laid along the entire length according to the principle: 2 rods are placed parallel to each other at the bottom and on top. For heavy structures, transverse reinforcement is also installed.

- Fill the tape with concrete and compact the solution well so that there are no voids left.

They wait until the tape is completely dry, only after that they begin to build brick pillars.

Laying brick pillars

Laying a brick fence

Laying a brick fence It’s quite easy to make a foundation for a fence with your own hands if you strictly follow the technology. Brickwork is made with metal rods for structural strength.

You can make a fence by following the rule: the pillars are laid as one-and-a-half (1.5 bricks) or double (2 bricks).

Fill the space created between the brick and the metal pillar with cement mortar with the addition of durable stone.

Lay the brick strictly on a vertical plane, check the level using a plumb line.

After completion of the work, the pillars are erected for 14 days. During this period, they are treated with impregnation that protects them from moisture.

You can put a metal cap on the upper end of the rack to protect it from precipitation getting inside and washing out the concrete.

Stone foundation

Fence with stone foundation

Fence with stone foundation A stone foundation is installed under massive heavy fences made of natural stone or brick.

The foundation for a fence made of corrugated sheets or other lightweight material should not be made of stone for the reason that it will be unreasonably expensive.

To figure out how to properly make a stone foundation, you need to learn how to calculate its surface and depth and know the technology of the device.

The stone foundation is installed in a previously prepared trench. Natural stone is placed in formwork on a pre-filled sand cushion and a layer of waterproofing material.

The process of installing a stone strip foundation is labor-intensive and expensive, so such a foundation is made quite rarely.

Base for a fence made of corrugated sheets

Corrugated fence

Corrugated fence Profile decking is often used for the construction of fences due to its high performance characteristics and low cost.

A fence made of corrugated sheets on a strip foundation will last more than 50 years.

They determine the dimensions of the platform and the depth of the foundation, and begin to construct a strip foundation for the fence with their own hands. Several assistants will be needed to complete the work.

The diagram for installing a strip foundation for a fence made of corrugated sheets with your own hands is described above.

The second option is to build the base of the fence from blocks, which are laid in rows in a trench. Each row of blocks must be filled with concrete and compacted well.

Holes for supports are provided in advance at a distance corresponding to the size of the profiled sheet for a metal profile fence.

A fence built according to technology from corrugated sheets, bricks, and concrete blocks will be a reliable support for the entire structure.It is important to correctly calculate the main parameters and install the structure strictly according to the level. Which foundation to choose is determined based onpreliminarycalculations.

Do-it-yourself fence is a profitable solution. In this case, there is no need to pay strangers: with the proper level of preparation, the work can be done independently. One of the most important parts of the structure is the foundation. Strength and reliability will depend on it.

At the moment there are no special regulatory documents for private construction. When designing and constructing, you can rely on “Foundations and Foundations”. The following sets of rules may also be useful:

- “Foundations of buildings and structures”;

- “Loads and impacts”;

- “Building climatology and geophysics” (now cancelled, but suitable for quickly determining the depth of soil freezing).

When designing a strip foundation for a fence with your own hands, it is necessary to take into account several factors that influence the dimensions of the structure, the depth of the base and the reinforcement of the strip foundation for the fence.

It is worth remembering that in private construction it is difficult to strictly adhere to regulatory documents. This can lead to waste of materials and labor.

Before making a strip foundation for a fence, you need to consider the type of fence. There are three main options:

- lungs;

- average;

- heavy.

Lightweight fences are made from posts and non-massive materials (mesh, reinforcement rods, corrugated sheets, wooden panels, picket fences). Such structures are highly resistant to uneven deformations. Fences with non-continuous filling (mesh, rods, picket fence) are also resistant to overturning under the influence of wind load.

Medium fences are a combined structure consisting of massive pillars (brick, stone, concrete) and lighter filling (corrugated sheets, reinforcement rods, picket fences). This option requires a more reliable foundation, since it is sensitive to displacement.

The third type of fences is heavy. They are made entirely of rubble, concrete or brick. Such fences are damaged when the base is deformed and also exert great pressure on the ground. The most difficult thing is to prepare the tape specifically for this design.

Main problems during construction

When designing a fence, it is important to take into account two phenomena:

- windage when exposed to wind loads (capsizing);

- uneven deformations of the base.

The latter include:

- soil shrinkage (its compaction after the foundations are made; sections of the fence may sink);

- frost heaving of the base (sections of the fence may rise).

To avoid troubles, it is necessary to take measures to combat frost heaving and carefully compact the base under the foundation.

Advice! You can understand whether the soil on your property is prone to heaving by looking at your neighbors’ fences. If they were “led” in different directions, most likely it was this property of the soil that was to blame. It is worth looking only at the fences that have stood for several winters.

Classification is carried out according to three main criteria. By manufacturing method:

- Made. Excellent for mass construction, increases the speed of construction work.

- Monolithic. Most often used in private construction. Avoids the need to hire expensive lifting equipment.

By depth:

- not buried with low bearing capacity;

- shallowly buried;

- deep laying.

By section type:

- rectangular;

- T-shaped section with widening at the bottom.

Light fences

In this case, there is no point in building a deeply buried foundation for a strip fence. This is not cost effective.

Under a fence made of corrugated sheets with your own hands, a shallowly buried rectangular strip will fit (laying depth - 0.7-1 m). When building it, it is important not to forget about the main problems: heaving and windage.

The width of the foundation is recommended to be at least 350 mm. In this case, in the upper part, in places where the tape and fence posts are rigidly connected, reinforcing mesh should be laid from rods with a diameter of 3-4 mm and a cell size of 50x50 mm. The protective layer of concrete for galvanized mesh is 30 mm, for “black” mesh - 60-70 mm. Such a mesh will prevent damage to the fence when exposed to wind (relevant for structures made of corrugated sheets and wooden panels).

Fence posts are usually supported below the base of the tape and concreted. This allows the fence to more effectively resist overturning and ground movement.

Lightweight fencing.

When laying the base of the foundation above the freezing depth, it is necessary to prevent heaving. The step-by-step instructions in this case are as follows:

- Backfilling a sand cushion with a thickness of 30 to 50 cm. Replacing heaving soil with non-heaving soil at the base level allows you to avoid pushing the structure out of the ground. The sand becomes a damping layer. It should be large or medium fraction. The material is laid with layer-by-layer compaction.

- Backfilling the sinuses with sand allows you to avoid the effect of heaving on the side surface of the foundation. The requirements for backfilling are the same as in the previous case.

- Laying a drainage pipe at the level of the sole (20-30 cm below). It is important to maintain the correct pipeline slope. The maximum distance from the drainage to the side surface of the tape is 1 m.

- Storm drainage system for organized removal of excess moisture from the site.

- Insulation and waterproofing of the structure with extruded polystyrene foam.

Important! The supporting structure for a fence differs from that for a house in that there is no point in making an insulated blind area.

A fence made of corrugated sheets on a strip foundation can be built without fear of frost heaving if the site contains non-heaving soils: medium and coarse sand, coarse rocks without dust inclusions.

Medium fences

Fences of this type do not respond well to uneven ground movements. To prevent destruction, great attention will need to be paid to combating heaving. On strong, non-heaving soils, a shallow tape can be used.

In other cases, it is reasonable to combine a shallow shallow foundation with concrete pillars or bored piles. Additional supports are placed under massive pillars. The depth is set so that it is greater than the depth of soil freezing. The methods used to combat heaving and windage are the same as in the case of light fences.

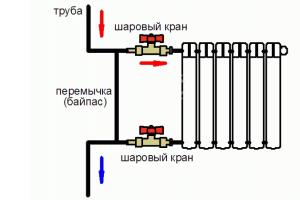

Another option: a columnar or pile foundation with a strip grillage. In this case, a gap of about 10-15 cm is left between the concrete tape and the ground, which will prevent damage to the tape when the soil bulges. The gap is made in two ways:

- A layer of low-strength foam is placed between the ground and the tape, which plays the role of a damping layer.

- Before pouring the structure, a layer of sand 10-15 cm thick is laid on the ground; after the concrete has hardened, the sand is removed. In this case, the gap is covered with sheets of asbestos (slate), which will prevent the soil from crumbling.

A fence made of corrugated sheets on a strip foundation with concrete pillars requires more attention than a lightweight structure.

Heavy fences

The greatest financial and labor costs will be required for the construction of a massive structure made of brick, stone or concrete. The design has the following disadvantages:

- large mass and high ground pressure;

- sensitivity to deformation;

- windage, the need to take into account wind loads.

In this case, the fence must be supported on a reliable foundation:

- If the soil strength is good, a shallow T-shaped tape can be used. This option is suitable for non-heaving substrates. Clay soils will require additional measures to combat heaving.

- In other cases, a buried tape is used, supported 20-30 cm below the freezing depth.

Every 30 meters in the tape it is necessary to provide a vertical expansion joint. It is necessary to provide a waterproofing layer between the foundation concrete and the fence material (brick, rubble). For this you can use rolled materials. The side surface is coated with bitumen in two layers to protect it from moisture.

Selection of foundation width

The width of the tape is selected by calculation. To do this, use the same methodology as when calculating the parameters of the foundation for a house. But it is important to remember about wind loads. The building has higher rigidity, so it resists tipping well.

In private construction, approximate values can be used. In most cases, having built a structure 30-35 cm wide, you don’t have to worry about reliability and strength.

Advice! If you need contractors, there is a very convenient service for selecting them. Just send in the form below a detailed description of the work that needs to be performed and you will receive proposals with prices from construction teams and companies by email. You can see reviews about each of them and photographs with examples of work. It's FREE and there's no obligation.

Owners of private households, summer cottages and private areas of land seek to protect their properties from uninvited guests and prying eyes by building fences. The more reliable and higher this barrier is, the greater the feeling of protection from the influences of the outside world. If you only plan to mark your territory, then the support pillars can simply be driven into the ground. However, for capital fencing, the laying of heavy types of reinforced foundation will be required.

What types of fence foundations are there?

The main function of the fence foundation is to distribute the weight of the entire fence structure evenly. A solid foundation will eliminate the possibility of rupture and deformation of such a structure.

The type of foundation being laid must meet the following criteria:

- the design features of the fence - the height and weight of the material used;

- the composition of the soil in the built-up area;

- the terrain of the earth at the site of the fence.

In accordance with the listed nuances, a shallow foundation is suitable for light barriers, and for more capital fences - monolithic heavy foundations using reinforcement.

It should be noted that before construction work it is necessary to examine the soil characteristics.

If this is neglected, an incorrectly selected foundation will cause deformation and distortion of the fence. As a result, you will have to rebuild everything, spending a lot of time and money.

The composition of the soil differs into several types:

- Soil containing a large amount of sand. During melting snow or heavy rains, such soil tends to shift. For such soil, it is better to use a strip foundation or a foundation on screw piles.

- Soil that contains a lot of clay and sandy loam is susceptible to freezing to great depths. This feature contributes to the appearance of quicksand, making it unstable. If there are a large number of large stones in such soil, then only a pile foundation should be used. If the clay composition of the soil has a homogeneous structure, then a strip base is suitable.

- Soil consisting of gravel does not have the property of deep freezing and displacement when exposed to moisture. For such soil, a columnar foundation is most suitable.

- If you plan to build a fence on rocky or solid stone soil, then any foundation other than pile and screw will serve as the foundation for it.

Tape

The strip base for a fence is a concrete structure, usually in the shape of an elongated parallelepiped, which is reinforced with a frame of reinforcing bars before hardening. In its solid state, the concrete strip is the basis for installing fence posts and spans.

Quite often, in order to strengthen the pillars being installed, the strip base has an extension in the form of a cube. This design feature helps strengthen the reinforcing pipe (vertical support) for the fence post.

When erecting a fence on unstable types of soil, the strip base is combined with other foundations. The strip foundation on concrete pillars has proven itself well. In the finished (hardened) state, this base is a solid reinforced concrete structure.

Thanks to its shape, this type of foundation evenly distributes the weight of the entire fence, increasing its stability. The strip base can be used both for heavy brick buildings and for light fences made of wood or profiled sheets. This gave reason to call it universal.

The strip base must be reinforced with metal rods with a thickness of 0.8 to 1.2 cm. For this, a volumetric frame is made from reinforcement, in which there are 4 or 6 long horizontal rods connected by elements of the same material. For these connecting parts, sections of reinforcing bars of the required length are prepared, which are fastened together by welding. The distance between long reinforcement is from 20 to 40 cm, depending on the width and height of the strip foundation. The distance between the connecting elements is usually in the range from 50 to 80 cm.

The construction of a strip foundation is a very expensive process, but such a foundation pays off due to its good stability and long service life.

From corrugated sheets

A fence made of this sheet material puts a slight load on the base. In this regard, only the support posts are subject to strengthening. A columnar foundation has proven itself well for such a fence.

This type of base is considered the most budget-friendly, as it consists of cylindrical or cubic pillars, with a height of 50 to 80 cm. A metal pillar is fixed in the middle of such a pillar.

The construction principle of such a foundation is that a metal pillar is driven into the bottom of the hole, and its voids are filled with concrete. When installing such a foundation, special attention should be paid to soil research, since a fence made of profiled sheets has a large windage area. If this is neglected, the posts in the fence will skew or become deformed under the influence of strong winds.

A columnar foundation can be strengthened with reinforcement. For this purpose, reinforcing bars with a length of 50 to 70 cm are used, from which a three-dimensional structure is made. Wire can be used as connecting elements. The image shows such a design.

A similar foundation is often used in the construction of wooden fences and chain-link fences

For brick fencing

Fences of this type are heavy, so the foundation for them must be solid. For a brick fence you need to use a strip or strip-column base.

The strip base should rise above ground level by at least 10–15 cm.

Depending on the looseness of the soil, a concrete strip can be combined with a columnar foundation, making expansions at the location of the pillars. It should be noted that a brick fence must have a pillar every 250 - 300 cm. These supports are necessarily reinforced with a channel, pipe or several reinforcing bars. A pillar is laid around such a rod.

This type of foundation is the most expensive, since in addition to a large amount of concrete, a lot of reinforcement will be required to make a reinforcing frame.

Under a fence with brick pillars

The foundation for this type of fence is a concrete pile with a thickening under a brick pillar. Such a foundation is completely buried in the ground. The pillar is laid from its zero level.

The pile foundation must be reinforced with metal rods. A profiled pipe is used as a reinforcing element for masonry pillars and concrete piles.

This type of foundation is less expensive than the previous option. Columnar base with thickening is successfully used in various types of soil, except solid stone.

How to pour a foundation correctly: we understand the technology

Before pouring concrete to make the foundation, it is necessary to calculate the proportions of the mixture and the total amount of materials for making the base.

In addition to the concrete mixture you will need:

- fine gravel;

- sand;

- reinforcing bars;

- edged board, thick plywood or OSB boards for making formwork;

- roofing felt;

- polyethylene;

- wire.

Proportions and calculation of concrete volume

To make a concrete mixture for pouring the foundation, you will need to maintain the proportions of cement, sand, filler (crushed stone) and water.

For this purpose, coarser-grained sand is used than that used in the manufacture of masonry or plaster mortar.

The most suitable size for crushed stone (crushed stone) when building a foundation is considered to be about 20 mm.

The proportions when mixing ingredients can vary significantly depending on the size and weight of the future structure, the characteristics of the filling materials and the climatic features of the area being built.

When using crushed stone with parameters of 20 mm, the proportions of cement, sand and crushed stone are used in the range of 1: 3: 6. If such a filler is smaller, then the indicated proportions change to 1:4:4. A foundation with the specified parameters is suitable for the construction of garden fences and other fences with relatively low weight.

For heavier structures, an ingredient ratio of 1:2.5:3.5 will be required. It should be noted that increasing the amount of sand in the mixture reduces the strength of the concrete base.

Calculation of the volume of concrete mixture

To pour the foundation, it is extremely important to know not only the proportions of the mixture, but also the required volume of concrete for the foundation. It is most convenient to carry out the calculation using a strip-column foundation as a template. Such a base combines all of the listed types of concrete bases: columnar (including with expansion) and strip. Visually, a fragment of such a base can be divided into the simplest geometric shapes: cube, parallelepiped and cylinder.

Using mathematical formulas from a school geometry course, it is easy to accurately calculate the volumes of these figures, as well as the total amount of mixture for the foundation.

As an example, a calculation will be made for a fence 16 m long. Let’s assume that the concrete pillars will be located at a distance of 2.5 m from each other. The diameter of each pillar is 0.15 m. First you need to set their total number to the specified length. To make it convenient to calculate, you need to use the parameters of the thickness of one column and one span: 2.5 + 0.15 = 2.65 m.

Now you need to find out how many such distances will fit into the length of the fence: 16:2.65=6.03. We need to add one more pillar, since it will be the outermost one, 6.03 + 1 = 7.03 rounded up to 7 pieces.

Based on the design of the strip-column base, there will also be 7 thickenings of the foundation. It should be noted that each thickening has a parameter of 0.4x0.4x0.4 m. Their total number in the foundation is calculated using the same principle. The span length in this case will be 2.15 m. Let’s substitute the values: 0.4 + 2.15 = 2.55 m.

We determine how many such distances will fit along the length of the fence (and add one cube): 16:2.55+0.4=6.27+0.4=6.67 pcs. In this case, you can make the fence a little longer or shorten one span. The number of spans will be equal to 6 pieces.

Using the obtained parameters it is easy to calculate the volume of concrete for each figure.

Calculation for pillars

To calculate the volume of the mixture for one cylindrical column, you need to use the appropriate formula: V=πR²h, where π is a mathematical constant equal to 3.14, expressing the ratio of the circumference to its diameter; R - radius of the circle; h is the height of the cylinder.

It should be noted that according to this formula the radius will be 0.075²=0.005625 m (according to the rules for rounding numbers, this value will be equal to 0.006 m). Let's substitute the values: 3.14∙0.006∙0.5=0.00942 m³ - this is the volume of concrete for one column. For all pillars: 0.0942∙7=0.06594 m³, rounded to 0.07 m³.

Calculation for thickenings

Since the foundation thickenings have a cubic shape, calculations must be made using the formula for calculating the volume of a cube, which is as follows: V=h³, where h is the height, length and width of the figure. Let's substitute the values: 0.4∙0.4∙0.4=0.064 m³.

Findable volume of mixture for thickening the entire foundation: 0.064∙7=0.448 m³.

Calculation for spans

The spans have the shape of parallelepipeds. To calculate their volume, you need to use the formula for the volume of a cube: 2.15∙0.4∙0.3=0.258 m³. We determine the total volume of the mixture for all spans: 0.258∙6=1.548 m³.

How to make a foundation for a fence with your own hands - step-by-step instructions

When the required volume of concrete has been determined and all materials for construction have been prepared, you can begin making a foundation for the fence. To do this, you need to perform the following construction steps:

- First of all, you need to make markings for the trench on the area being built. To do this, it is convenient to use cords stretched over stakes.

- Along the planned lines, dig a trench 45 cm wide, 70 cm deep, 16 m long. The parameters of the trench are made larger than the dimensions of the foundation itself, since a reserve is needed for installing waterproofing and formwork.

- When digging the trench is finished, its bottom needs to be leveled. To do this, it is convenient to use a homemade manual tamper. To make it, you need to attach a smaller block to the end of a log or thick beam, which will serve as a handle. The result will be a T-shaped structure.

- Then, using a hand drill, at a distance of 215 cm from each other, dig holes with a diameter of 20 cm. If such a tool is not at hand, then you can use a fishing ice drill. The depth of such holes should be 60 cm.

- Pour sand into the bottom of each hole to form a layer of 5 cm. It must be remembered that wet sand compacts better.

- The bottom of the trench also needs to be covered with sand to create a uniform layer of 10 cm.

- After this, pour a layer of fine gravel, 5 cm thick, into the holes. At the bottom of the trench, this layer should be 10 cm.

- Now it is necessary to cover the internal surfaces of the trench and holes with waterproofing material. As such, you can use roofing material. For holes it is convenient to use asbestos-cement pipes of the appropriate diameter.

- For a strip-column foundation, it is necessary to make a strengthening (reinforcing) frame. For this purpose, corrugated reinforcing bars with a diameter of 8 to 12 mm are used.

- Install asbestos-cement pipes into the holes. You can use roofing material rolled into a pipe

- Install metal structures in the holes. It is necessary to take into account that the reinforcing frame in the holes should rise above its upper edge by 15–20 cm.

- Pour the concrete mixture into the holes.

- It takes time for the mixture to set. Usually 4 to 6 days are enough for this. After this, you can begin further construction activities.

- Cover the walls and bottom of the trench with roofing material

- Place a reinforcing frame made of reinforcing bars at the bottom of the trench. It should be noted that the metal structure should not touch the bottom of the trench. To do this, the frame is placed on bars or fragments of bricks. Alternatively, you can drive pieces of reinforcement into the bottom to which the entire structure can be secured.

- Since the surface of the foundation will rise 10–15 cm above ground level, formwork will need to be made for pouring. To do this, you will need thick plywood, edged boards, OSB boards or other material from which you can make a strong and even barrier. To prevent the sides of the formwork from falling apart under the pressure of uncured concrete, they are strengthened with struts and spacers.

- To prevent concrete from sticking to the formwork, its inner surface can be covered with thick polyethylene, securing it with staplers.

- Pour the prepared concrete mixture into the formwork. In order for the foundation to be strong, it must be laid in layers. It should be noted that during pouring, concrete is mixed with air, which causes a lot of bubbles to appear in the mixture. Their presence makes the base fragile. To remove them from uncured concrete, use a deep vibrator. If such a device is not at hand, then you can use a stick or reinforcing rod, bayoneting the mixture many times.

- The poured concrete must completely cover all elements of the reinforcing frame. Concrete, even in its liquid state, can have an uneven surface. Therefore, before it hardens, it is necessary to level it with a rule or a wide board with smooth edges.

- Once the foundation is poured, it will take time to harden. Typically this period is from 6 to 10 days. This period is applicable for air temperatures from +5 to +40°C. If pouring is carried out at low temperatures, the hardening time will increase to 3–4 weeks. At temperatures below 10–12 °C, pouring is not recommended. It should be noted that the concrete mixture tends to quickly lose moisture. Therefore, after pouring and leveling, you need to cover the foundation with thick polyethylene. This promotes uniform hardening and protects from exposure to sunlight. In addition, for the first two days, the surface of the foundation must be moistened with water. If these actions are neglected, the frozen base will become covered with cracks, which can lead to a fracture of the concrete base.

- When the specified period has passed, you can remove the formwork and begin further construction work on erecting the fence. The surface of the finished foundation must be cleaned of dust and debris, and only then can construction of the fence begin.

Video: making a foundation for a fence

A properly selected and poured foundation will make the fence structure resistant to temperature changes in the soil. Accurate calculations will eliminate unnecessary costs for the purchase of materials and concrete mixture.

The construction of a fence begins with solving a difficult problem: it is necessary to choose a foundation for the fence. On the one hand, it is necessary that it does not get mowed down in the spring, during heaving, on the other hand, there is no desire to bury extra money. So we have to solve the puzzle, choosing which of the foundations is needed - just put up pillars, cast a strip tape, or settle on an intermediate option - a columnar one with a grillage.

What kind of foundation can there be for a fence?

No matter how many fence designs there are, they all stand on several types of foundations. The depth, diameter or cross-section of pipes, width and depth of the base may differ. These parameters depend on the climate zone and the material from which the fence spans are made. But there are not very many designs and ways to implement them:

The designs are arranged in order of increasing cost: the least expensive is the first method, the most expensive is the fourth. The choice of foundation for the fence depends primarily on the type of soil and the level of groundwater. If the soil drains water well and the groundwater level is low - below the freezing depth - it can be installed on any structure. If the groundwater is located high, you want a “serious fence” made of brick or rubble, for example, and the soil is clay or loam - you will have to make a more serious foundation, which costs a lot.

If you don’t know how deep the water is in an area, dig a pit near the planned fence. Its depth is 50-70 cm below the freezing depth for the region. If you have dug to this level, but there is no water, then you are lucky and you can make a fence with the base of any structure.

Installing posts for a lightweight fence

A lightweight fence is one whose spans are covered with relatively low-weight materials: chain-link mesh, wood of any design, corrugated board, metal picket fence, welded or forged metal mesh. Pillars without plinths are most often placed under them.

Posts for a mesh fence or picket fence

The cheapest and most universal way is in a wide hole and filling the gap with crushed stone. It works great on heaving soils with a high groundwater level, and costs many times better than poured concrete. A light fence installed correctly using this method will never be pushed out in the spring.

The cheapest, and yet most reliable way to install a fence is with pillars in a compacted backfill.

Holes for posts of this type are obviously drilled much wider than the diameter of the pipe. They poured crushed stone or sand onto the bottom, compacted it (with a long pole or crowbar), set up a post, covered it with crushed stone around it, set the post up vertically and secured it with temporary spacers. Pour crushed stone around in layers - 10 cm each, carefully compact it to the maximum possible density. That's it, the installation is complete.

On normal soils

It is worth explaining why it is more stable and how such a pillar works on soils with normal drainage ability. Water in any quantity goes deep through the crushed stone, where it disperses naturally. When freezing, the amount around the pillar is not enough to have a noticeable effect. The soil freezing around the pillar puts pressure on the crushed stone, which, due to its mobility, compensates for it almost completely.

It is better to make a foundation for a fence made of corrugated sheets by pouring the upper part with concrete, otherwise wind loads will cause the posts to loosen over time (see the next paragraph)

On such soils, crushed stone can be replaced with coarse sand. The coarser the grain, the better, but dusty or fine-grained sands are not suitable. Lay the sand in layers, pour it thoroughly. Otherwise the whole system works the same.

The key point here is the depth to which the post must be buried. If the windage is small and the soil drains well, it is enough to bury it to 1/3 of its height or a little more. In this case, the hole needs to be made a little deeper: so that there is a cushion under the pipe of about 10-15 cm. Water will go into it and the column will remain almost dry. This is good for both its durability and stability.

Depth of holes for pillars in heaving soils

If the soils are clayey, it is necessary to dig 10-15 cm below the freezing depth. Water will collect in this crushed stone cushion, since they do not always have time to drain on clayey soils. If the pillow is located below the freezing depth of the soil, there will be no problems with heaving: there is still no water around the column, it has accumulated below and is in a liquid state.

If the freezing depth is very large - 2 meters or more, even this “economy” option will be very expensive. Then you can make a drainage system around the fence to lower the groundwater level. The decision is correct, but implementation is even more expensive.

Another option is to use screw piles. They can be drilled 2 meters much faster. But the piles themselves, and the services for their installation, are not the cheapest. You can, of course, try it manually first; if that doesn’t work, call the technician.

The most budget-friendly option in such a situation is to bury the pillars to a depth that is more or less acceptable, make the hole wider - about 50 cm in diameter or a square with the same side, that is, increase the damping layer. In winters with average temperatures, the fence will stand normally, but in abnormally cold or little snow some pillars may fail. But in most cases, light fences react to this normally, and in the spring everything “sits” into place. It is necessary to correct the position only if the pole is skewed.

Posts for a light but “sailing” fence

If the spans have a continuous or almost continuous surface, the wind creates a decent load on the foundation pillars of the fence. But if the weight of the filling is still small - corrugated sheets, wooden panels - you can still get by at low cost. In this case, to compensate for the wind load, the upper part of the backfill must be concreted. The depth of the concrete block is about 30 cm.

To prevent the concrete block from being destroyed by gusts of wind, a reinforcing mesh is laid. You can use a ready-made mesh with a pitch of 5 cm, you can make it from a 6-8 mm rod. If the mesh is galvanized, it is placed so that it is buried in the concrete by at least 30 mm (monitor the distance from the sides). When using ferrous metal, the layer of concrete along the edges of the rods increases: at least 70 mm. In total, the dimensions of the concreted area with a ferrous metal mesh are: depth 30 cm, sides - at least 34 cm, with a galvanized mesh, the side of the square around the column is 30 cm.

Foundation for fences on loose soils

If the bearing capacity of the soil is very low - these are peat bogs, dusty, loose sand - in addition to backfilling with crushed stone, the hole must be concreted to the full depth. In this case, the measure is necessary. Concrete creates a significantly larger supporting surface, and this is important for these soils: the load from the fence is distributed over the entire surface and it stands normally.

Cheaper in this case are bored-rammed piles: a hole is drilled, a sleeve of roofing material rolled into a tube of suitable diameter is inserted into it, preferably 2 or 3 layers. A pole is inserted inside this formwork, set up, and around it is filled with concrete grade M 300 and no lower.

If the groundwater level is high, but the inflow rate is low, you can try to pump it out of the hole and then fill it with concrete. If the water arrives quickly, take a plastic bag of suitable length. It is lowered inside the formwork, the edges are secured around the protruding sleeve. A pole is carefully placed in the bag and concrete is poured. Concrete gradually displaces water and fills the entire form.

The second method is suitable if below, under peat or sand, there is a layer of soil with normal bearing capacity. In this case, you can make a foundation for the fence on screw piles. They are twisted to the required depth - going 20-25 cm into the supporting layer. Fence posts are attached to the protruding heads, or the remaining length of the pile is used.

If you want to make a fence on brick pillars, the work and costs will be more significant. Even if the weight of the span remains small - corrugated sheets, wood, forging with some kind of material, paired or without it - it doesn’t matter. You will have to make a serious foundation for the pillars themselves, because they themselves create a serious load.

Such fences do not respond well to uneven shrinkage. A mortgage is usually placed in brick pillars, which is then connected to the crossbars of the entire fence. The connection turns out to be rigid, and with uneven shrinkage, cracks appear in the places where the mortgage is attached, and the destruction of the masonry begins. Therefore, the minimum permissible level of foundation for a fence with brick pillars is below the depth of soil freezing. This approach will ensure stability.

Normally draining, medium-heaving soils

Even if the water drains well, in order for the fence to stand for a long time, you have to dig below the freezing depth. But still, significant forces act on that part of the pile body that falls into the freezing zone. When freezing, the soil and concrete freeze into a single mass, and then heaving forces are able to break the pile and squeeze out a piece of the fence.

To avoid such a situation, the foundation for the fence is made in permanent formwork. In this case, the soil cannot freeze with the concrete and “works” on its own. As formwork, you can use several layers of rolled roofing felt, polystyrene foam or polystyrene foam (even packaging from household appliances will do), plastic or asbestos-cement pipes of a suitable diameter.

In any case, there must be reinforcement inside the pile. This is a structure of 4 bars of 8 mm reinforcement, connected by crossbars of 4-6 mm bars. It goes to the entire depth of the pile, with an outlet into the pillar. Then, if desired, you can increase the reinforcement and fill the gap between the bricks in the column with concrete. The second option is to attach a pipe to the fittings, around which a column is placed. Recently, this has been a more common method of constructing a brick pillar.

TISE piles are more reliable in such a situation. They have a cylindrical flare at the end, which significantly increases the resistance to buoyant force. Such foundations for a fence can be made on slightly and moderately heaving soils.

To make this type of piles, a drill with a folding blade is used, which folds back after reaching the required depth. In order for such a foundation to work normally, it is advisable to make the expansion below the freezing depth.

But it is not always possible to drill with a hand drill. On very dense clays and soils with crushed stone, drilling a hole can be unrealistic. And if the freezing depth is about 2 meters or more, then it may be impossible to cope with such a task. In such cases, there are several solutions:

After pouring, piles on normal soils are backfilled with “native” soil; on those prone to heaving, it is better to fill them with crushed stone. In this way, a damper backfill will be created around the pile, compensating for the lateral soil pressure on the pile. And the vertical pushing will be resisted by the pillow.

Very heaving soils

If the freezing depth is too great or the soil is very heaving, another solution is required. It is necessary to tie the foundation pillars to distribute the resulting loads. For fences with stone pillars, but light filling, this is done using a grillage - a reinforced concrete strip. To prevent it from being bent by heaving forces, an air cushion about 10 cm thick is placed underneath it.

Such a foundation for a fence is built like this: after pouring the piles, a trench is dug, which is larger in size than the required grillage: formwork will need to be installed. Low-density foam plastic, 10 cm thick, is laid at the bottom of the trench and around the piles. A reinforcing frame is made: four rods of 10 mm in diameter, connected with a 4-6 mm rod. The pile outlets are combined with grillage reinforcement. Everything is filled with concrete. After setting, the formwork is removed, the foam remains under the grillage. It provides the required air gap: with a low density, it consists of 90% air. After winter, of course, it will shrink, but that’s not a big deal: the air will remain. But to prevent sand or debris from falling into the cracks, it is necessary to bury flat slate on both sides, which will block this crack, preventing it from silting.

The same grillage can be made on screw piles. If they suit you better, everything remains in effect - their cutting parts are buried below the freezing level, and then everything is the same as with a grillage, ditch, formwork, polystyrene foam, reinforcement, filling.

Why shouldn't you put sand or crushed stone under the grillage? Because in this case it will be wet and most likely will not help much when it freezes. As a result, the grillage will burst.

Foundation for a heavy fence

In principle, the same foundation as for a medium-weight fence will do. You just need thicker reinforcement: 12 mm. When reinforcing, it is necessary to place the rods so that they are at least 70 mm deep in the concrete. Based on this, and the requirement that the minimum distance between the reinforcement bars must be at least 2 infill diameters, we obtain a minimum grillage width of 250 mm. This is if the concrete is filled with crushed stone of a fraction of 20-40 mm.

In addition to the usual grillage reinforcement, it is advisable to lay a layer of metal mesh on the upper longitudinal bars in increments of 5 cm. It will give the upper zone of the tape greater strength. And you can start laying the infill 2 weeks after pouring, rather than 4.

The grillage is made in exactly the same way: with the formation of a damper layer of foam underneath it. After the concrete has gained most of its strength, it is advisable to coat it with bitumen mastic. This is necessary not so much for waterproofing, but to reduce adhesion to the soil. Since the grillage under a heavy fence is most often located in the ground, it is also affected by tangential heaving forces. To reduce them, coating is necessary.

Don't forget also about the sheet blocking access to the damping zone under the grillage. Without it, after some time the gap will silt up, which will lead to heaving under the tape, and this will lead to the appearance of cracks in the fence.

Is it possible to make a strip foundation for a stone or brick fence? Can. If you make it below freezing level, it will stand great, but it costs a lot more.

The content of the articleAs a rule, the construction of a permanent fence on a site is carried out either before the construction of a house begins, or after its construction, that is, at the moment when all the information about the condition of the soil is known. Such soil data is necessary to correctly calculate the strip foundation for the fence.

We all know that strip foundations are quite often installed under the walls of a residential building, but the loads taken by such a foundation are much higher than those of a strip under a fence.

Features of strip foundations

Since the loads from the fence structure are much smaller, the requirements for such foundations are low. And yet, a fence installed on a concrete strip will be much more reliable and durable.

As a rule, strip foundations are provided for the following types of fences:

- a fence with brick pillars;

- wrought iron fence;

- a fence made of timber or corrugated sheets with supporting metal posts.

As a rule, a strip foundation for a fence is a continuous reinforced concrete strip of shallow depth. To construct such a belt, concrete grade M 200 class B 15 is used. It is not recommended to lower the grade of concrete.

The casting of the strip foundation for the fence is carried out over a sand bed. A rod with a diameter of 8 -10 mm is used as reinforcement. If you use not ordinary formwork, but laminated formwork, then the concrete surface of the foundation, rising above the ground, turns out to be smooth and even. It can be easily painted in the desired color, which will add decorativeness and originality to the fence.

The depth of the strip foundation for the fence (as well as the width) is selected depending on the design of the fence itself. The higher the weight of the fence, the wider the tape needs to be made.

Thus, for metal welded fences with significant weight, it is necessary to make the widest possible strip, and the laying depth can be small. But for fences made of corrugated sheets, you can use the narrowest tape, but the depth of its laying must be significant. This is due to the high windage of the fence.

Construction of fences on strip foundations

The process of installing strip foundations for fencing consists of the following technological stages.

We dig a trench 30-80 cm wide, the depth of the trench depends on:

- climatic conditions of the construction region,

- soil stability,

- weight and fencing design.

As a rule, the foundation laying depth ranges from 60-80 cm.

A gravel-sand cushion is laid at the bottom of the trench and then compacted. The pillow is generously moistened with water.

Then the reinforcement is welded. Longitudinal reinforcement rods are laid at the bottom of the trench on supports 5-7 cm high from scrap materials. The outermost bars of the reinforcement should retreat from the walls of the trench by 7-10 cm.

Then the reinforcement is welded. Longitudinal reinforcement rods are laid at the bottom of the trench on supports 5-7 cm high from scrap materials. The outermost bars of the reinforcement should retreat from the walls of the trench by 7-10 cm.

Transverse reinforcement and vertical posts are knitted in increments of 400 mm.

The top row of longitudinal reinforcement is attached to the posts so that it is 5-7 cm below the top level of the trench. Then the transverse reinforcement of the top row is laid.

Making a strip foundation for a fence is unthinkable without formwork. It is at this stage that we begin its construction. For this purpose, we use a 25 mm thick edged board. We prepare the panels in such a way that the foundation strip protrudes 300 mm above the ground level. We make a box from the panels and secure it in the trench by installing spacer bars and adding soil.

Now you can pour the concrete strip. If the fence design includes load-bearing posts, then they must be installed in the trench and leveled before pouring concrete.

Moreover, concreting can be done in two ways:

- continuous laying of the concrete mixture, without waiting for the setting of the previous layer;

- laying concrete with breaks for the previously laid layer to set.

For shallow trenches, the first installation method is suitable. To increase the durability of volumetric foundations, it is better to use the second method.

After the concrete tape has completely hardened, you can remove the formwork and add soil. The foundation is ready!

If you want to study in more detail the construction of a strip foundation for a fence, a video on this topic can be found on the Internet.

Separately, I would like to mention the situation when, when constructing a fence with support posts, a shallow foundation strip is used. In this case, concreting the pillars in the tape will not be enough for their stability, so it may be necessary to additionally drill a well about 90 cm deep under each pillar. After installing and concreting the pillars in the pits, you can make a regular shallow strip foundation using the method described above.