LED floodlights are a very popular thing today. But, like any electronics, spotlights break down relatively often. Today's article will be devoted to repairing LED spotlights with your own hands.

All the theory on the design of LED spotlights and terminology, and here is practice for home craftsmen.

The spotlight doesn't light up - where to start?

First of all, you need to make sure that 220 V power is supplied to the driver. This is Azy.

Checking the driver

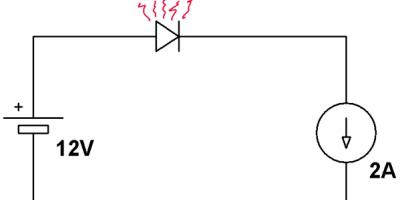

Let me remind you that the word “driver” is a marketing ploy to designate a current source designed for a specific matrix with a certain current and power.

In order to test the driver without an LED (idle, without load), simply apply 220V to its input. A constant voltage should appear at the output, a value slightly greater than the upper limit indicated on the block.

For example, if the range of 28-38 V is indicated on the driver unit, then when it is turned on idle, the output voltage will be approximately 40V. This is explained by the principle of operation of the circuit - to maintain the current in a given range of ±5%, when the load resistance increases (idle = infinity), the voltage must also increase. Naturally, not to infinity, but to some upper limit.

However, this test method does not allow us to judge whether the LED driver is 100% serviceable.

The fact is that there are serviceable units that, when turned on idle, without load, either will not start at all, or will produce something unclear.

I suggest connecting a load resistor to the output of the LED driver to provide it with the desired operating mode. How to choose a resistor - according to Uncle Ohm's law, looking at what is written on the driver.

LED driver 20 W. Stable output current 600 mA, voltage 23-35 V.

For example, if Output 23-35 VDC 600 mA is written, then the resistor resistance will be from 23/0.6=38 Ohms to 35/0.6=58 Ohms. We choose from a range of resistances: 39, 43, 47, 51, 56 Ohms. The power must be appropriate. But if you take 5 W, then it will be enough for a few seconds to check.

Attention! The driver output, as a rule, is galvanically isolated from the 220V network. However, you should be careful - cheap circuits may not have a transformer!

If, when connecting the required resistor, the output voltage is within the specified limits, we conclude that the LED driver is working.

Checking the LED matrix

For testing, you can use a laboratory power supply. We supply a voltage that is obviously lower than the nominal voltage. We control the current. The LED matrix should light up.

What to do if the power of the LED module is unknown

There are situations when there is an LED chip, but its power, current and voltage are unknown. Accordingly, it is difficult to buy it, and if it is working, it is not clear how to choose an adapter.

This was a big problem for me until I figured it out. I am sharing with you how to determine from the appearance of an LED assembly what voltage, power and current it is.

For example, we have a spotlight with the following LED assembly:

![]()

9 diodes. 10 W, 300 mA. In fact - 9 W, but this is within the margin of error.

The problem is that the LED matrices of the floodlights use 1 W diodes. The current of such diodes is 300...330 mA. Naturally, all this is approximately, within the margin of error, but in practice it works accurately.

In this matrix, 9 diodes are connected in series, they have one current (300 mA), and a voltage of 3 Volts. As a result, the total voltage is 3x9 = 27 Volts. For such matrices, you need a driver with a current of 300 mA, a voltage of approximately 27V (usually from 20 to 36V). The power of one such diode, as I said, is about 9 W, but for marketing purposes this spotlight will have a power of 10 W.

The 10 W example is a bit atypical due to the special arrangement of the LEDs.

Another example, more typical:

![]()

You already guessed it two horizontal rows of dots of 10 pieces each are LEDs. One strip is, offhand, 30 Volts, current 300 mA. Two strips connected in parallel - voltage 30 V, current twice as much, 600 mA.

A couple more examples:

![]()

Total - 50 W, current 300x5 = 1500 mA.

![]()

Total - 70 W, 300x7 = 2100 mA.

I think there is no point in continuing, everything is already clear.

The situation is slightly different with LED modules based on discrete diodes. According to my calculations, one diode there usually has a power of 0.5 W. Here is an example of a GT50390 matrix installed in a 50 W floodlight:

![]()

LED floodlight Navigator, 50 W. LED module GT50390 - 90 discrete diodes

If, according to my assumptions, the power of such diodes is 0.5 W, then the power of the entire module should be 45 W. Its circuit will be the same, 9 lines of 10 diodes each with a total voltage of about 30 V. The operating current of one diode is 150...170 mA, the total current of the module is 1350...1500.

Anyone who has other thoughts on this matter is welcome to comment!

LED spotlight driver repair

It is better to start repairs by searching for the electrical circuit of the LED driver.

As a rule, LED spotlight drivers are built on a specialized MT7930 chip. In the article about the Design of Spotlights, I gave a photo of a board (not waterproof) based on this microcircuit, once again:

LED floodlight Navigator, 50 W. Driver. GT503F board

![]()

Attention! Information on driver circuits and a little more on repairs!

LED replacement

There are no special tricks when replacing the LED matrix, but you need to pay attention to the following things.

- Carefully remove old heat-conducting paste,

- Apply thermal conductive paste to the new LED. It is best to do this with a plastic card,

- fix the diode evenly, without distortions,

- remove excess paste,

- do not confuse the polarity,

- Do not overheat when soldering.

![]()

When repairing an LED module consisting of discrete diodes, first of all you need to pay attention to the integrity of the soldering. And then check each diode by applying a voltage of 2.3 - 2.8 V to it.

Where to get spare parts for repairs

If you need quick repairs, then the best thing, of course, is to run to the store across the street.

But if you are engaged in repairs on an ongoing basis, then it is better to look where it is cheaper. I recommend doing this on the well-known AliExpress website.

I provide several links for reference and examples, there is a lot of interesting information there, including descriptions, photos and selection.

LED matrices:

- Led Chip large selection from 10 to 100 W, from 48 to 360 rubles.

- Powerful LEDs.

Drivers for LED spotlights, for different powers:

- 30W waterproof DC power supply,

- 50W waterproof DC power supply,

- Waterproof Outdoor LED Drivers 10, 20, 30, 50W DC.

And who doesn’t want to repair, you can immediately order something ready-made:

LED street floodlights:

- Outdoor floodlights from 10 to 50 W,

- Waterproof flat floodlights from 10 to 100 W, LED Chip+Driver kit available.

To complete the picture, here is a video from my colleagues, they share their experience:

I'll end here. I encourage my colleagues to share their experiences and ask questions!

My previous job generously supplied me with corpses of LED lamps and fixtures. Without going into technical details, more than 99% of what is sold everywhere is outright slag, fundamentally incapable of working for any long time due to clearly insufficient, or even absent, cooling.

Here is an example of complete slag: a bullshit pure plastic “radiator”. the result is predictable: the LEDs are burnt out, blackening of the crystals is visible, and they self-soldered out

another dead guy

The “old-style” LED spotlights with a solid-cast aluminum radiator body were relatively well made, but they are rapidly disappearing from sale.

![]()

old style spotlight

![]()

old style spotlight

But, apparently, the sellers and Ketai people decided that so much lumini was too fat, and they optimized these spotlights. Now “new sample” floodlights with a plastic housing and a separate radiator are on sale everywhere.

![]()

New 30W floodlight

The cartridge was supplied for sizing purposes. The radiator has a fin area of approximately 200 sq.cm. The result is predictable: the heatsink heats up around +100 degrees, rapid degradation and failure of the LEDs

![]()

Guts floodlight 30W

Please note: there are 60pcs of 0.5W LEDs type 5630. diodes are used 100%. Reserve by mode? what nonsense, have not heard. And my electronics teacher back in the 80s used to say that those who use components at >60% of the limiting modes are either idiots or greedy bourgeois.

Here the circuit design of the emitter is as follows: 2 parallel groups of 30 serial 5630. The forward voltage is around 90V at +25g r, and the current is 300mA.

The LEDs are mounted on a luminous board, which is screwed only at the corners. The fit is loose.

the result is in the photo. In a measly 100 operating hours, the phosphor had already become very black, several diodes burned out, burning black holes in the phosphor. The driver also died. I re-connected the groups of LEDs in series, the driver was down-graded to a stupid capacitor one.

![]()

emitter large

It was experimentally found that such a radiator is capable of maintaining a reasonable temperature on the crystals in the region of +80°C and +60°C on the radiator, with only 1/3 of the nominal power of the spotlight. This is what I did, the current was reduced by three times.

The picture is approximately the same for other powers of spotlights of this type: terrible overheating and rapid dying

morality? Avoid purchasing such “new style” floodlights; if possible, look for solid cast “old style” floodlights.

By the way, pay attention to the drivers of different spotlights. They do not have a class capacitor in the rectifier. This is how manufacturers fight for a decent cosine phi. Needless to say, the 100Hz output ripple is enormous. Output capacitors do not help. Do not use such spotlights where you work for a long time, protect your eyes. At a minimum, it is useful to add electrolyte to the rectifier, at least 10 µF for every 10 W

Also note that all drivers, and those of LED lamps too, are made according to the “step-down” scheme, i.e. there is not a transformer, but a choke, and there is no isolation from the network! Be extremely careful! The chip-to-substrate insulation is clearly not designed for mains voltage.

![]()

LED floodlight drivers

Power

The power of the driver must match the power of the spotlight, or more precisely, the matrix in the spotlight. Do not rely on the power indicated on the body of the spotlight! We have had spotlights brought to us for repair many times, proudly labeled 50W in half a body with a 30-watt driver and matrix inside. Installing a 50-watt driver in such a product will not end well. It is imperative to read the labeling of the burnt driver.

Dimensions

The driver must physically fit inside the LED floodlight. And you still need to lay the wires.

We have the exact driver sizes listed on our website.

Driver output current value

The output current value is always indicated on the driver housing. This is the current that the driver will supply to the matrix. This value varies from approximately 300mA to 3000mA and must match the matrix supply current. Deviations of more than 5% are unacceptable.

Output voltage range

The driver output voltage range is the two voltage values within which the driver attempts to stabilize the current.

Numbers can range from 20 to 150 volts.

This range must coincide with the corresponding characteristic of the matrix, or, if it is unknown, the range of output voltages of the burnt driver.

This parameter does not have to match as closely as the current value, but there should be an approximate match.

Input voltage - 220 volts

We produce different drivers for LED spotlights, not only for 220 volts. Therefore, when purchasing a driver, make sure that you have a driver for the input voltage you need - all drivers presented in this section are designed for 220, 127 and 110 volt networks.

For those who haven’t read it, let me remind you briefly. Recently, a powerful 120 W LED floodlight was brought in for repairs; it only worked for a year. As it turned out, his driver burned out. And there I started whining about the fragility of switching power supplies and wondered about finding a simpler and more reliable solution. Today I decided to assemble and test the operation of a circuit with a quenching capacitor. A similar circuit is widely used to power LED spotlights.

Preliminarily calculated the capacity of the quenching capacitor using the well-known formula

![]()

For the calculation I took the following parameters:

Uc (mains voltage) = 220 V;

U (voltage at the input of the diode bridge) = 60 V;

I (nominal LED current) = 1.8 A;

According to calculations, it turned out that a capacitor with a capacity of 27 μF is needed. I went through the bins, collected all sorts of different capacitors to provide the required capacity, and also experimented with the deviation of the capacity from the calculated value. To avoid misunderstandings, the capacitance of all capacitors was measured with an E7-16 immittance meter.

![]()

![]()

Despite the venerable age of some specimens, the capacity practically corresponded to the specified one.

![]()

I soldered the circuit. In order not to bother too much, I used the power part from the computer power supply board. The result is this design

![]()

It was interesting to find out to what extent the current will change when the input voltage deviates by 20% from the nominal value with different values of the quenching capacitor capacitance. The experiments were carried out with LEDs preheated for 30 minutes. The measurement results were tabulated and presented in graphical form. During the measurement process, the voltage on capacitor C2 varied within 58 V...62, I decided not to include these values in the table due to their insignificant change.

![]()

The graphs turned out to be linear

![]()

The native driver ensured that the current flowing through the LEDs was maintained at a level of 1.8 A. According to various sources, the rated current of a 60 W LED ranges from 1.8 to 2 A, different sellers indicate different currents. We will assume that a current above 1.8 A is undesirable.

If you choose a capacitor with a capacity of 24 μF, then when the input voltage increases to 260 V, the current through the LEDs will not exceed the rated value. In normal mode, with an input voltage of 220 V, a current of 1.5 A is provided, which corresponds to a power consumption of 90 W. At a rated current of 1.8 A, the calculated power is about 110 W. Thus, with an input voltage of 220 V, we have a power reduction of 20 W (18%) relative to the nominal value. On the one hand, a lower current value increases the service life of the LED, but leads to a decrease in the brightness of the glow, although this is not particularly noticeable to the eye. It would be nice to measure the brightness with an appropriate device, but it is not available.

LED spotlights are a type of lighting equipment that combines high efficiency and cost-effectiveness. Despite their long service life, they also fail, and their owners have to contact repair shops. However, not all faults are so complex that it is impossible to repair the LED spotlight yourself. Let's look at the causes of breakdowns, diagnostic methods and criteria by which you can find out whether self-repair is possible.

LED spotlight design and typical faults

An LED spotlight (LED) is a bright lighting device consisting of:

- LED emitting light;

- driver that controls the operation of the device;

- housings;

- a diffuser that increases the efficiency of the device;

- lenses that determine the shape, color and other parameters of the light flux.

The most common malfunctions in the spotlight are driver failure or LED burnout. The latter greatly lose brightness or burn out due to the fact that the thermal energy they generate is poorly removed into the atmosphere. This problem is typical for budget manufacturers who skimp on radiators.

Combustion or unstable operation of the driver is a problem typical for Chinese-made floodlights, in which manufacturers also save on literally everything. However, using these products can be beneficial if you know how to organize electronics. Chinese spotlights are very cheap and work well after the driver has been restored.

The spotlight stopped lighting - how to fix it?

First of all, in this situation, you should check whether the device driver is receiving power with a voltage of 220 V. If this is all right, you should first diagnose and repair the driver. It can be checked without connecting an LED by applying electric current to the input. If the device is working correctly, measuring the output with a multimeter should show a DC voltage that will be slightly above the rated limit. For example, for a driver with an output voltage of 28-38 volts, when running idle, the multimeter will show ~40 volts. This is explained by the fact that an increase in load resistance (due to idle operation) leads to an increase in voltage.

However, this method does not help to accurately check all drivers. There are blocks that, in good condition, will either produce illogical data or will not start at all. In such a situation, a load resistor that simulates the consumption of an LED will help you check the device. It must be selected in accordance with the characteristics of the driver. For example, with a DC output current of 23-35V 600 mA, the resistor resistance should be in the range from 23/0.6 = 38 Ohms to 35/0.6 = 58 Ohms.

If the output voltage with the load resistor connected meets the specifications, the driver operates correctly.

The easiest way to repair an LED floodlight if the driver has failed is to replace this component. You can purchase a suitable model not only in specialized stores, but also on the Internet. For example, Aliexpress offers a wide variety of spare parts, although you need to be very careful there to choose a quality product (sometimes even the sellers themselves have little understanding of the issue). Sometimes suitable drivers can be found from craftsmen who professionally repair floodlights. And if the LED spotlight was made from diodes with your own hands, then understanding its structure and fixing the problem will be even easier than buying or assembling a new one.

How to select a driver if the power of the LED module is unknown

Many hobbyists have situations when it is necessary to work with a spotlight, the power, current and voltage of the LED chip in which are unknown. Accordingly, in such a situation it is more difficult to select a replacement and driver.

Here you need to count the number of diodes in the LED matrix and add up their indicators. Such LED modules use diodes with a voltage of 3 V, a current of 300-330 mA and a power of 1 W. Accordingly, the total matrix voltage is 27 V with a current of 300 mA (when connected in series). Accordingly, a driver with an output voltage of 20-36 V is required for operation.

Let's give an example with a more complex matrix, which consists of two parallel-connected rows of diodes. Each row has a voltage of approximately 30 V with a current of 300 mA. Due to the parallel connection, the driver must have an output of 30 volts and 600 mA.

Eliminating flickering LED spotlights

Sooner or later, every owner of an LED spotlight encounters a problem. The reason for this behavior may be improper operation of electronic components or loss of performance of LEDs. In this section we look at how to repair an LED floodlight with a power of 10 W. This power is most common, and the general design of the devices is similar, so the solution to the problem is universal.

The LED is a matrix of 9 crystals, each of which has a power of 1 W. These crystals are connected in three sequential circuits and filled with phosphor - a substance that converts the received energy into light. A 10 W LED consists of three lines of crystals, which are connected in parallel to the power coming from the driver.

Burning out one of the crystals in the LED will cause it to blink during operation. The nature of blinking can be either periodic, with equal pauses, or chaotic. For various reasons, matrix combustion can lead to a complete shutdown of the LED element, or to the failure of one or two lines of crystals.

Why does the matrix blink or does not light up when it burns out?

The crystals, filled with phosphor, are connected to each other by leads, which in the case of high-quality products are made of gold, and in budget devices - of copper. Heating the matrix and connecting contacts too much causes these filaments to peel off from the crystals. Therefore, the entire matrix or part of it is turned off. After cooling, the thread returns to its original position and work resumes. After reheating to a critical point, the contact is interrupted again and the matrix goes out. This cycle continues endlessly during operation, and to the observer it looks like a flashing lamp. Complete LED failure occurs when one of the filaments overheats so much that it falls off the crystal.

Knowing about this behavior, you can check the condition of the matrix of diode spotlights with your own hands. To do this, you need to arm yourself with a not too sharp object and press on those places in the matrix where the connecting threads pass. Of course, the spotlight must be on at this time. If the device lights up when pressing on one of the paths, the problem has been found. In this case, all that remains is to correctly replace the damaged chip.

Important information! A matrix in which at least one line of crystals has burned out should be replaced immediately. The remaining lighting elements will lose efficiency and quickly fail.

This happens because the crystals are connected in a parallel-series matrix, and the power from the driver is supplied in the form of direct current. Therefore, after one line burns out, the remaining two receive a current strength 1.5 times higher than the rated one. Working under increased load leads to even greater heating of the matrix and rapid combustion of other threads.

Repairing the matrix

Replacing an LED when the crystals on the matrix burn out is not an overly complicated procedure. After purchasing a component with similar characteristics and the special thermal paste required for installation, you need to:

- Disassemble the spotlight body by unscrewing the mounting bolts on the body.

- Remove the lens or glass.

- Remove the diffuser.

- Unscrew the matrix mounting screws and carefully unsolder the conductive leads. A non-contact soldering station with a hot air gun is best suited for this.

- Lubricate the new LED with thermal paste.

- Solder the contact pins of the LED and screw the fasteners back on.

When connecting an LED, it is extremely important to maintain the polarity of the terminals. Experienced installers also recommend replacing the wiring when replacing an LED in inexpensive Chinese floodlights. Manufacturers, as a rule, use material with a minimum cross-section, which is not entirely reliable. In this case, it is better to use heat shrink tubes. They retain their insulating properties even when exposed to heat emanating from the diode.

LED floodlights are in great demand among consumers for illuminating shop windows, store facades, courtyards in private homes and other objects. They are durable, have good light intensity and consume much less energy compared to conventional incandescent lamps.

But any equipment has a certain service life and is not guaranteed against breakdowns, therefore it requires repair. It is always cheaper to fix problems yourself than to contact specialists in workshops. Let's look at a simple repair of some faults on LED floodlights, but before describing the repair process, you need to study what types of floodlight designs there are and the principle of their operation.

LED spotlight operation

The voltage from the power source is supplied to the electronic board, the converted current is supplied to the LED element, which emits streams of light. The designs of spotlights may be different, but they all have common elements:

- Power supply;

- Electronic current and voltage conversion board;

- Operating mode control drivers;

- Heat sink;

- Optical elements, lenses, mirrors built into the body;

- Terminals for connecting wires and fixtures for fastening the housing.

Floodlights have LEDs of different sizes and power, but the principle of operation and symptoms of malfunction are common.

Basic spotlight malfunctions

Most often, the malfunction of spotlights is manifested by the following symptoms:

- Complete absence of glow when turning on the power;

- LED flickering;

- Dim glow, not at full power;

- Changing the shade of emitted light;

There are obvious signs of deformation of the housing, destruction of the LED structure, after mechanical shocks or breakage, burnt out wiring, which are visible visually.

Main causes of malfunctions

Manufacturers make LED matrices and conversion boards that are reliable and, if used correctly, guarantee a minimum trouble-free period of up to 5 years. Most often, malfunctions occur for the following reasons:

- Unstable characteristics of the electrical network, voltage and current surges exceeding the operating mode values;

- Short circuit of a phase to the spotlight body or neutral wire;

- Incorrect connection;

As a result of these violations, the electronic board on which the floodlight control drivers, voltage and current converters that power the crystal structure of the matrix with LEDs are programmed may fail.

The LED matrix in spotlights can consist of several dozen elements. If the structure of 3-5 crystals in the matrix is destroyed, the spotlight can function, but with a larger number of faulty elements, irreversible processes disrupt the operating mode and all the crystals burn out. In this case, a complete replacement of the matrix is required.

Diagnosing a fault on an LED floodlight

Let's consider identifying a fault on a floodlight, which is in greatest demand among consumers, rectangular in shape with a matrix of 9 diodes, with a power of 10 W. One of the models in this series is the Volpe 10W floodlight with a luminous flux of 750 Lumens.

Regardless of the brand of spotlight, diagnostics begins with a visual inspection:

- The integrity of the wiring from the power source is checked, the absence of breaks, burnt insulation and kinks in the cable, where there may be a break in the current-carrying conductor hidden under the insulating layer;

- The body of the spotlight and the LED matrix are inspected for absence of deformation, cracks and chips;

- If there is no light at all, first of all you need to unscrew the back cover of the case and check the voltage at the input and output of the electronic board of the converter. There should be 220V AC at the input; if there is no voltage, then the reason is not in the spotlight, but in its power supply circuit; measurements can be carried out with a conventional multimeter. The output terminals are 12V DC.

- If there is no voltage at the output, the fault should be looked for on the voltage converter board. Inspect the board for oxidized contacts, tin cracks in solder areas and burnt parts;

- If there are no signs of malfunction in all of the listed points, the last element remains, this is the LED matrix.

Repair and replacement of faulty elements of LED spotlights

Faults such as broken wires can be resolved quickly and do not require special qualifications. The most difficult repair is identifying a faulty element on the driver circuit board, voltage converter and replacing the LED matrix. Therefore, to make repairs yourself, you must have certain knowledge and practical skills in electrical engineering, be able to read diagrams, use measuring instruments and a soldering iron. If you don’t have such experience, it’s better to turn to specialists.

The simplest way is to replace faulty elements with similar ones; they can be purchased from electrical goods or removed from spotlights on which other parts are faulty. Assemble one working one from two or three faulty ones. A matrix with LED crystals filled with compound material cannot be repaired.

Tip No. 1 If 2-3 diodes out of 9 have burned out in the matrix, then you don’t have to wait for it to burn out completely; this can have a detrimental effect on the drivers and voltage converter. Change the matrix at the first sign of malfunction.

Replacing the spotlight matrix

- Unscrew the front cover of the case, which presses the glass;

- Unscrew the screws and remove the reflector;

- Unsolder and unscrew the faulty matrix;

- We solder the new matrix and assemble the spotlight in the reverse order.

Sometimes the wires from the printed circuit board pass to the matrix through holes in the metal substrate, which acts as a heat sink for the matrix. At the transition points, they must be insulated, especially the positive wire, so that there is no short circuit to the housing.

Tip No. 2 When replacing the matrix, wipe its substrate and the surface on which it is screwed. Lubricate these places with heat-conducting paste, only then screw the matrix to the body.

When replacing the matrix, be sure to observe the polarities, the red wire is positive, blue or black is negative, yellow-green is on the body.

LED floodlights are a very popular thing today. But, like any electronics, spotlights break down relatively often.

Today's article will be devoted to repairing LED spotlights with your own hands.

All the theory on the design of LED spotlights and terminology, and here is practice for home craftsmen.

The spotlight is not on - where to start?

First of all, you need to make sure that 220 V power is supplied to the driver. This is Azy. Next, it remains to decide what is faulty - the LED driver or the LED matrix.

Checking the driver

Let me remind you that the word “driver” is a marketing ploy to designate a current source designed for a specific matrix with a certain current and power.

In order to test the driver without an LED (idle, without load), simply apply 220V to its input. A constant voltage should appear at the output, a value slightly greater than the upper limit indicated on the block.

For example, if the range of 28-38 V is indicated on the driver unit, then when it is turned on idle, the output voltage will be approximately 40V. This is explained by the principle of operation of the circuit - in order to maintain the current in a given range of ±5%, when the load resistance increases (idle = infinity), the voltage must also increase. Naturally, not to infinity, but to some upper limit.

However, this test method does not allow us to judge whether the LED driver is 100% serviceable.

The fact is that there are serviceable units that, when turned on idle, without load, either will not start at all, or will produce something unclear.

I suggest connecting a load resistor to the output of the LED driver to provide it with the desired operating mode. How to choose a resistor - according to Uncle Ohm's law, looking at what is written on the driver.

LED – driver 20 W. Stable output current 600 mA, voltage 23-35 V.

For example, if Output 23-35 VDC 600 mA is written, then the resistor resistance will be from 23/0.6=38 Ohms to 35/0.6=58 Ohms. We choose from a range of resistances: 39, 43, 47, 51, 56 Ohms. The power must be appropriate. But if you take 5 W, then it will be enough for a few seconds to check.

Attention! The driver output, as a rule, is galvanically isolated from the 220V network. However, you should be careful - cheap circuits may not have a transformer!

If, when connecting the required resistor, the output voltage is within the specified limits, we conclude that the LED driver is working.

Checking the LED matrix

For testing, you can use a laboratory power supply. We supply a voltage that is obviously lower than the nominal voltage. We control the current. The LED matrix should light up.

What to do if the power of the LED module is unknown

There are situations when there is an LED chip, but its power, current and voltage are unknown. Accordingly, it is difficult to buy it, and if it is working, it is not clear how to choose an adapter.

This was a big problem for me until I figured it out. I am sharing with you how to determine from the appearance of an LED assembly what voltage, power and current it is.

For example, we have a spotlight with the following LED assembly:

9 diodes. 10 W, 300 mA. In fact - 9 W, but this is within the margin of error.

The problem is that the LED matrices of the floodlights use 1 W diodes. The current of such diodes is 300...330 mA. Naturally, all this is approximately, within the margin of error, but in practice it works accurately.

In this matrix, 9 diodes are connected in series, they have one current (300 mA), and a voltage of 3 Volts. As a result, the total voltage is 3x9 = 27 Volts. For such matrices, you need a driver with a current of 300 mA, a voltage of approximately 27V (usually from 20 to 36V). The power of one such diode, as I said, is about 9 W, but for marketing purposes this spotlight will have a power of 10 W.

The 10 W example is a bit atypical due to the special arrangement of the LEDs.

What's new in the VK group? SamElectric.ru ?

Subscribe and read the article further:

Another example, more typical:

You already guessed it two horizontal rows of dots of 10 pieces each are LEDs. One strip is, offhand, 30 Volts, current 300 mA. Two strips connected in parallel - voltage 30 V, current twice as much, 600 mA.

A couple more examples:

Total - 50 W, current 300x5 = 1500 mA.

Total - 70 W, 300x7 = 2100 mA.

I think there is no point in continuing, everything is already clear.

The situation is slightly different with LED modules based on discrete diodes. According to my calculations, one diode there usually has a power of 0.5 W. Here is an example of a GT50390 matrix installed in a 50 W floodlight:

LED floodlight Navigator, 50 W. LED module GT50390 – 90 discrete diodes

If, according to my assumptions, the power of such diodes is 0.5 W, then the power of the entire module should be 45 W. Its circuit will be the same, 9 lines of 10 diodes each with a total voltage of about 30 V. The operating current of one diode is 150...170 mA, the total current of the module is 1350...1500.

Anyone who has other thoughts on this matter is welcome to comment!

LED spotlight driver repair

It is better to start repairs by searching for the electrical circuit of the LED driver.

As a rule, LED spotlight drivers are built on a specialized MT7930 chip. In the article about the Design of Spotlights, I gave a photo of a board (not waterproof) based on this microcircuit, once again:

LED floodlight Navigator, 50 W. Driver. GT503F board

Attention! Information on driver circuits and a little more on repairs!

LED replacement

There are no special tricks when replacing the LED matrix, but you need to pay attention to the following things.

- Carefully remove old heat-conducting paste,

- Apply thermal conductive paste to the new LED. It is best to do this with a plastic card,

- fix the diode evenly, without distortions,

- remove excess paste,

- do not confuse the polarity,

- Do not overheat when soldering.

When repairing an LED module consisting of discrete diodes, first of all you need to pay attention to the integrity of the soldering. And then check each diode by applying a voltage of 2.3 - 2.8 V to it.

Where to get spare parts for repairs

If you need quick repairs, then the best thing, of course, is to run to the store across the street.

But if you are engaged in repairs on an ongoing basis, then it is better to look where it is cheaper. I recommend doing this on the well-known AliExpress website.

I'll end here. I encourage my colleagues to share their experiences and ask questions!

Although LED technology is very reliable, it cannot be perfect and sometimes fails. Especially if you decide to save a lot and purchase one of the cheapest floodlights. So what to do if your LED floodlight, or even worse, stopped working altogether, and your warranty on the purchased product has expired, or did not start at all. It is quite possible that you purchased an uncertified product from a reliable store with a good reputation, and at your own peril and risk ordered the most affordable LED spotlight directly from China, through Aliexpress, for example? And now a far from cheap lighting device lies in front of you and blinks or does not shine at all, and you don’t know what to do? Don't give up. In this article we will tell you how to repair the device yourself.

In order to repair an LED processor with your own hands, you must confidently hold a multimeter (in the picture below) and a soldering iron in your hands. This is necessary in order to be able to determine the cause of the breakdown, and, in fact, ultimately eliminate it, returning the device to life.

Probable causes of failure and ways to eliminate them

Current limiting capacitor

So, first of all, you need to determine the cause of the malfunction of your device. If the spotlight turns on, but when turned on does not burn evenly, but flickers and blinks, the current-limiting capacitor C1 has probably failed. Many Chinese manufacturers make the mistake of using a current-limiting capacitor that does not match the parameters of the driver when trying to achieve maximum brightness from a not very powerful spotlight. A current-limiting capacitor at 400 volts rated operating voltage will do just fine.

power unit

Another common cause may be a failed power supply. There are two ways out of the situation - go to an electronics store, where they will help you choose a suitable power supply (its characteristics are indicated on it, therefore it is advisable to disassemble the spotlight and take the unit with you), or select a power supply (may be suitable from a scanner or printer).

The second option is possible, of course, only if you suddenly have unnecessary and non-working office equipment lying around that can serve as a power supply donor. Check the power supplies so that they are similar in parameters. An exact match is not necessary, but the parameters should not diverge too much. As mentioned earlier, if you have the skills to use tools and understand electronics, you can easily change the power supply yourself.

Driver

If a low-power spotlight needs repair, it is likely that it may not have its own power supply, and the function of changing currents in it is performed by the LED driver. Since the LED cannot be powered directly from the network, requiring an alternating current that differs from what the network can offer it, the spotlight uses a driver that takes into account the variation in the characteristics of the LED depending on the operating temperature and time, adjusting the output current supplied to the LED . It is this driver that can fail.

To replace it, you will need to disassemble the LED spotlight and find out the driver markings in order to buy or order a replacement. If you are a confident user of power tools, you can find a failed driver element and unsolder it and replace it. If you are repairing, most likely it will be quite easy for you to find the problem in the driver or find a similar driver and replace it. It will definitely be cheaper than buying or assembling a new spotlight from scratch.

Matrix burnout

Another option for failure of the design of your LED spotlight, in addition to a malfunction of the driver, power supply or other small elements involved in the current conversion process, may be the burnout of the LED matrix itself. If the LED itself fails, you need to find and purchase a diode with similar characteristics. After disassembling the spotlight, you will need to carefully uninstall the burnt matrix by unscrewing the four fastening screws and unsoldering the conductive elements. Then you will need to evenly and carefully apply a layer of thermal paste to the new diode, solder the current-carrying elements and carefully screw the matrix. It is necessary to take into account that the shape of the matrix must remain intact, that is, it is advisable to use the same screws that were originally used. They should not have conical heads, because if you use them, if you tighten them with a little more force, they can damage the matrix and all your work will be in vain.

Let's sum it up

To repair an LED spotlight yourself, you must at least have good skills in working with a soldering iron, testers and a multimeter, as well as understand circuit diagrams or be able to read them in order to find the cause of the malfunction, unsolder the faulty element and replace it.

If the driver or power supply in your spotlight fails, you can find a replacement and bring the lighting device back to life. Just like with the driver, a replacement can be made with an LED matrix - just buy an analogue with similar characteristics. If for some reason the device does not work after your manipulations, it probably makes sense to purchase a new one. But if you are confident in your abilities, you can always assemble an LED spotlight with your own hands - it will be easier to repair it in the future, or replace some elements, constantly extending the life of the device.