The need to use soldering equipment may arise at any time, even at home, but not every master knows how to ensure that its technical capabilities meet the current need.

And to understand this, you need to understand the technical potential of modern soldering equipment.

Soldering requires not only the presence of a soldering iron, but also the necessary components, the minimum set of which consists of a control module and a spring holder.

For using a soldering device at home, this is the optimal configuration option, capable of providing a stable temperature, protection from overloads and static.

Whereas a standard soldering station for special purposes, including industrial, can also be equipped with:

thermal tweezers (used for installation and disassembly of miniature components);

local heating hairdryer (used as an auxiliary heater at the soldering site);

thermal emitter (used to heat the board when group soldering is performed);

vacuum tweezers;

auxiliary fittings.

Depending on the purpose of the soldering station, its configuration may include devices for highly specialized operations.

It is the complete set that ultimately determines the classification of soldering equipment.

The soldering station can be:

hot air - this type of device is equipped with a hair dryer and provides for soldering with hot air;

induction - is a miniature, but very powerful and durable device;

pulse - used for installation and dismantling of any modern circuit;

infrared - along with gas soldering irons, this is the best opportunity to repair a mobile phone or tablet yourself.

Technological features of the use of soldering stations

Depending on the type of soldering performed, devices are divided into 2 categories - lead and lead-free.

Lead soldering equipment is equipped with a module that regulates the heating level of the tip. These can be either devices whose operation is based on electricity, or induction-type stations.

A characteristic feature of induction stations is that their operation is ensured by an alternating magnetic field.

In this case, each soldering element is processed with a different power, the selection of which is carried out automatically, since the device independently determines the heat capacity of the soldering component.

The use of induction soldering stations is convenient to operate and has high heat dissipation.

In cases where it is necessary to solder small circuit elements or hard-to-reach components, the non-contact soldering method is used. Non-contact soldering stations include hot-air and infrared soldering stations.

The operating principle of infrared soldering equipment is based on the properties of infrared rays obtained from ceramic or quartz elements.

The main area of application of infrared-type stations is computer circuits and motherboards.

Thermal air stations operate on the principle of point transfer of hot air, so they can be used to easily warm up hard-to-reach elements without touching adjacent contacts.

This type of soldering device is usually used in workshops for repairing household electronic and mobile equipment.

Nuances of operating various types of soldering equipment

The technological diversity of types and categories of soldering equipment significantly complicates its choice.

Therefore, before giving preference to any model, it is worth familiarizing yourself in detail with their technical potential and recommended scope of application.

Craftsmen who use a regular soldering iron at home are well aware of the situation when the sensitive elements of the device overheat, and it is not possible to adjust the temperature.

This is one of the reasons why it is better to choose a soldering station over a soldering iron.

Because the station is equipped with a power supply, and with its help you can change not only the voltage, but also the temperature of the device.

However, it is not enough to simply choose a soldering station with a thermal stabilization system. It is also important to consider the power of the device, especially if refractory solders are used.

Otherwise, negative consequences cannot be avoided:

excessive soldering temperature leads to overheating of circuit components;

the durability of the soldering iron tip is sharply reduced due to overheating;

the shelf life of the heating element is reduced;

the tracks on the board overheat;

soldering quality is unsatisfactory.

In such cases, it is recommended to pay attention to equipment specifically designed for lead-free soldering - firstly, the power of such devices is much higher, and secondly, they can also be used for lead soldering.

Methods for controlling soldering equipment

Considering that soldering stations are one of the main tools in the field of electronics production, and the level of demand for them is high, multifunctional devices have been created that combine the technical capabilities of various types of equipment.

Such devices are distinguished by the connection of several modules, allowing the use of contact or non-contact soldering, as well as the use of several nozzles and tips.

When choosing soldering equipment, the method of controlling the station deserves special attention. It can be digital and analog.

Analog-type devices require constant monitoring, because when a certain temperature point is reached, they must be turned off so that the soldering tip does not overheat.

On the other hand, after turning off the device, the temperature drops, and in order to solder, you must wait until it rises again.

Digital type devices operate thanks to appropriate software, which provides control of the tip heating temperature automatically.

This means that the digital control method provides a more stable and accurate level of temperature maintenance than the analogue one.

Principles for choosing a soldering station

The main task of soldering equipment is to ensure high-quality connection of elements, which in turn depends on the following design and technical parameters:

- A type of heating element. Modern manufacturers offer soldering stations with two types of heaters - ceramic and nichrome. Ceramic heaters heat up quickly, but are sensitive to uneven heating and can crack. But with thermal stabilization, ceramic heaters show good heat transfer, high power and durability. Whereas nichrome is not able to ensure long-term operation of the heater and is therefore recommended for infrequent use. True, a nichrome heater costs much less than a ceramic one;

- Range of adjustable temperature indicators;

- Warm-up speeds;

- Power. As a rule, the quality level of a soldering station depends on the feasibility of its operation. It all depends on what kind of soldering is required and for what components. Therefore, power is one of the most important parameters that determine the choice of soldering equipment. Especially if the device will be used to repair such sensitive types of equipment as mobile phones, tablets, navigators, etc.;

- Voltage;

- Ergonomic indicators - weight, size, shape.

Also, objective factors influencing the choice of a soldering device are:

- Standards accepted by the international community that provide for lead-free soldering. This means that to ensure soldering you will need equipment with an operating temperature of 250 °C;

- Placing microcircuits in BGA packages. On the one hand, this is justified, since it allows you to reduce the size of products. On the other hand, this complicates all soldering-related processes due to the inaccessibility of components.

Other important points when choosing a soldering station

Regardless of what type of soldering station you choose, experienced craftsmen recommend providing yourself with a supply of replacement tips in advance.

Different types of tips differ in shape and edge area, and the final soldering result largely depends on these parameters.

First of all, because the larger the edge area, the better the heat transfer during the soldering process. And secondly, not only the type of elements being processed, but also its temperature can depend on the shape of the tip.

Therefore, good manufacturers make sure that the material from which the soldering tips are made has good heat dissipation.

Also, when choosing, you should pay attention to the ability to replace parts of the soldering equipment if they fail.

There is no point in investing in equipment that cannot be repaired.

There are still people who like to do things with their hands. Indeed, it’s nice to prepare a gift for a loved one yourself, for example, making an original photo frame or fixing the radio so you can listen to your favorite programs. A soldering station can be a good helper in such matters. But first, it’s worth understanding what it is and how it works.

Types of soldering stations

When working with modern miniature circuit boards, it is not very convenient to use conventional soldering irons with a copper tip. Installation and repair of such equipment is best performed using soldering stations of various types.

According to the basic principle of operation, there are contact and non-contact stations. The first ones are like a regular soldering iron with a temperature controller, which was previously used by radio and television technicians.

Working with microcircuits

Modern electronic devices use very small parts, such as microcircuits with a large number of contacts. They cannot be attached or removed in the usual way. To do this, use non-contact soldering, which is based on heating the contacts using infrared radiation or a stream of hot air.

Using Contact Soldering Stations

The main distinguishing feature of such stations is the use of various solders: tin with lead or without lead. Technically both stations are very similar. Soldering irons have a ceramic heater, a temperature sensor, and one conical tip (to perform different jobs, it is advisable to purchase a set of tips suitable for the soldering iron).

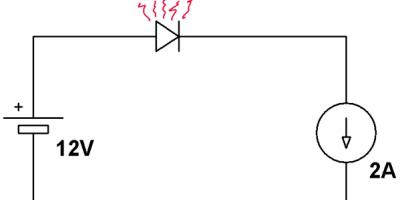

The power consumption is forty watts, the voltage is twenty-four volts, there is grounding, so you can work with parts that are afraid of static electricity.

The temperature can be adjusted from two hundred to four hundred and eighty degrees with an error of several degrees, which can be controlled using the indicator installed on some models.

It is necessary to have spare nozzles. They differ in configuration and are designed for soldering different parts. To decide what tips are needed for a soldering station, you need to consider all possible options for upcoming work that may arise in the future.

We must not forget about the correct choice of material from which the nozzles are made because different metals do not have the same thermal conductivity.

Principles of temperature control

The operation of analog stations is based on periodically turning on and off the current supply to heat the soldering iron, depending on its temperature. It is practically impossible to maintain it accurately, so the tip often overheats.

Digital soldering stations use a temperature controller programmed by a microcontroller, which significantly increases the accuracy of maintaining the required temperature of the tip.

Lead free soldering

A characteristic feature of such a station is the increased power of the soldering iron: from 75 to 160 watts. Such solder has a high melting point, so the place where the parts are attached must be well heated.

At the same time, such a station can also be used to work with thin tracks because the temperature controller will not allow the tip to heat up above the set temperature. You can also use leaded solder.

Contactless soldering stations

Contact soldering stations are convenient for soldering parts, but the reverse process is better done with a soldering station with a hair dryer. Such devices have a wide range of prices because they differ in the configuration of certain functions. Usually, nozzles are supplied with different outlet diameters to change the width of the heated air jet.

The hair dryer body has a fan that changes its performance depending on the position of the regulator. The air temperature can also be changed.

The shutdown process has a very useful feature. First the heating element turns off, and a little later the fan turns off. This is done in order to cool the hair dryer after use.

Hair dryers with individual electronics have an improved design. They are equipped with round nozzles, have a temperature regulator and air jet strength. The digital indicator displays the degree of heating of the exhaust air. It is convenient to use a hairdryer if the fan is built into the handle and not into the control unit. Then the hair dryer is connected with ordinary wires and there is no hard rubber tube, which somewhat interferes with movements.

Nozzles of various configurations are available for sale to work with many microcircuits. They help not only to remove parts, but also to solder them in the right place, and when working with a regular soldering iron, to heat the parts for better fastening. The main thing is to figure out which nozzles are suitable for certain hot-air soldering stations.

You can use a hair dryer to do other things that don't involve soldering, such as heating up tubes to attach to a metal extension cord, joining plastic parts, or drying something.

Station manufacturers

German (Ersa) and Chinese (Quick, Lukey, Aoyue) soldering stations have good technical characteristics on the market today. Their equipment and prices are very different, so everyone chooses according to their needs.

Professionals can choose Aoyue Soldering Station – 2702 a. In addition to a hair dryer and soldering iron, it has a desoldering gun and a smoke catcher, which improves the comfort of the workplace. Personal experience will tell you which station to choose - expensive or reliable.

Possibility to build with your own hands

How to make a soldering station? What components of a soldering station can you make yourself? To repair or manufacture microprocessor-based equipment, you most often need a couple of devices:

- hair dryer supplying heated air;

- infrared thermal emitter;

As a heater, you can use a soldering iron filament wound around a ceramic tube with fiberglass insulation.

Make the output nozzle from a heat-resistant ring. The power required is about 500 watts. A small fan can be used as a compressor. To regulate the air temperature, it is necessary to install a thermocouple.

Often, to repair a computer processor, you need an infrared soldering iron. It consists of the following parts: lower heater, upper heater, tripod and control unit.

The heater can be made from a nichrome spiral or a halogen lamp. The lower and upper blocks are steel boxes. To control the temperature, two thermocouples are used - on the processor body and on the surface of the motherboard.

Thus, the soldering station is a good assistant for both the home craftsman and the professional.

Soldering station photo

Classic soldering irons with a copper tip, which are familiar to many from school, are practically inapplicable for soldering modern small circuit boards and microcircuits. They can be used, but in very specific cases - for repairing household appliances or printed circuit boards, for example. Modern electronics require a more subtle approach. Both professionals and radio amateurs today are increasingly resorting to installing universal soldering stations. In order to make the right choice of soldering station, you need to consider many factors.

First thing you need to know

Today, all soldering stations are divided into two main groups:

- contact- they are ordinary analog soldering irons with tin-lead or lead-free solder

- contactless- in this case, the work is carried out due to heating and rapid injection of air or heating by infrared radiation

Each of these types has its own specific application. Today, many radio amateurs install non-contact soldering stations, but both of the above types have the right to exist.

Contact soldering irons: classics with a modern twist

Contact soldering stations are not the most modern units. Typically, such a soldering station comes with one conical copper tip, but most models allow you to expand the kit and purchase the necessary tips. As a result, you can solder almost anything with such a soldering iron, except memory boards in complex electronics. When choosing, you should pay attention to the possibility of expanding the kit if you want to get a truly universal device.

Contact soldering stations can have two types of control:

- analog- in this case, the soldering iron will have only two regulation positions - on and off, that is, the tip heats up to the desired temperature and turns off, and after cooling it starts to heat up again

- digital- in this case, the device will be able to maintain a constant temperature, that is, heating and soldering will be more uniform

The preferred option is tin-lead solder. It melts at a lower temperature, so you can work with such a soldering iron faster. Lead-free solder has a higher melting point, so if you want to buy such a soldering station, you should make sure that it has a sufficiently powerful heater.

What are the advantages of contactless stations

Non-contact soldering stations are more advanced devices. They come in two types:

- air - heating is produced by pumping hot air

- infrared - heating occurs due to infrared radiation

Choosing a soldering station of this type is an organic and natural solution for those who want to keep up with the times. It is contactless stations that are developing the fastest today - manufacturers are equipping their equipment with new additional functions that make work more comfortable and the result better quality.

For example, previously there were only air soldering stations with a blower built into the base. From it came a thick and hard tube through which air was supplied. This was not very convenient, since the rigid hose hampered the user’s movements. Today, soldering stations with a supercharger in a handle are increasingly appearing, from which only thin and flexible wires stretch to the base.

Heating element type

When choosing, you should also pay attention to the type of heating element. It can be of two types:

- ceramic- a layer of resistive substance and a thermistor are applied to the ceramic base

- nichrome- nichrome wire (wire) is wound onto a ceramic base (rod)

Ceramic heaters are convenient, but can deteriorate due to uneven heating. If the slightest crack forms, such a heater completely fails. At the same time, the price for it is much higher than for nichrome.

Choosing a nichrome heater is a more informed decision. Its main advantage is its lower price. However, it is also not without its shortcomings. It takes quite a long time to warm up, and with intensive use it quickly breaks down (in about six months).

The power of the soldering station should also be selected correctly. First, decide what you will use it for - you can solder radio equipment, electronics, or even large objects (as funny as it sounds, even buckets). If we are talking about soldering electronics and sensitive microcircuits, then a power of 40-60 Watts will be sufficient, however, for an ideal result it is better to provide a power reserve of at least 10 Watts.

The same applies to tension. For example, when working with sensitive circuits, it is best to choose low-voltage soldering stations. They are ideal because they will not allow sensitive boards to be “killed” by a power surge. Also in this case, it is best to pay attention to a soldering iron with an anti-static electricity function - all for the same purpose.

Additional functionality for efficient work

Before deciding which soldering station to choose, you should decide on its configuration. Today, devices are equipped with several additional functions:

- a set of attachments for precision soldering - it can include from two to fifteen attachments of different configurations, it is not worth mentioning that the richer the equipment of the device, the higher the price

- the presence of a hot air gun - this device is necessary for desoldering microcircuits, the presence of this addition is especially important for contact soldering irons - without it it will simply be impossible to desolder the circuit

- smoke absorbers are an optional, but very useful feature, first of all, it affects the comfort of working with the device, and moreover, your body cannot be harmed if you do not constantly breathe harmful gases and acrid smoke

- solder suction or desoldering gun - useful when desoldering circuits, it allows you to quickly and cleanly remove melted solder from the surface of the circuit and immediately continue work

- protection against static electricity - important when working with thin electronics that are sensitive to voltage surges

Soldering stations with a full range of the described functions have only one significant drawback - high price. They can cost more than 20 thousand rubles, so they cannot be called affordable for ordinary radio amateurs.

When choosing a soldering station, you should pay attention to the type of heating element, power and voltage - these are the main parameters that will allow you to choose the ideal model. Also decide on the type of station itself - contact or contactless. Amateurs today still buy contact stations with a copper tip, and professionals are increasingly paying attention to air and infrared non-contact ones. At the final stage, pay attention to the additional functions that a particular model offers.

Using a soldering station may also be necessary at home (for beginners), for different needs and situations. But the problem can be choice - not everyone knows what signs, characteristics and nuances to use to do this. In order to understand this issue, you need to familiarize yourself with the technical potential of the soldering iron, namely: functions, heating capability, power, etc. In this article we will try to talk in detail about how to choose a soldering station and which is better in 2017.

What does the kit consist of?

When carrying out soldering work, you need not only a soldering station, but also complete parts: a control and monitoring module and a spring holder. All this will be able to provide the required temperature and protect against overloads.

Depending on the specific operation of the soldering station, the kit may include:

- tweezers (soldering and removing small parts);

- hair dryer for heating (additional heating of the soldering area);

- heat emitter (heating the board when soldering the group);

- vacuum tweezers;

- additional fittings.

Equipment classification

Depending on the specialization of the soldering iron, certain components are included. To choose the right soldering station, you must remember that the configuration determines the operating profile of the device.

There are four types of soldering irons:

Based on this, we summarize - in order to choose one or another model, you need to know initially what will be soldered with this soldering iron.

Technical features

When choosing, you need to know that according to the type of soldering, two categories can be distinguished:

- lead;

- lead-free.

Lead devices are equipped with a module that regulates the temperature level of the soldering tip, which makes the work more accurate and of better quality. Mechanisms based on electricity and an induction type station, for the operation of which a magnetic field is generated. By using such a device you get high heat output.

When soldering hard-to-reach components, non-contact soldering (hot air or infrared) is used. Infrared is used for circuits in computers or motherboards. Thermal air (point transfer) - for heating inaccessible parts, without affecting nearby parts. This option is best chosen for soldering plastic, as well as setting up household appliances and mobile phones.

Operation of soldering stations

Today there are many types of equipment for the technical part of the soldering device, and this significantly complicates the choice when purchasing. Because of this, before choosing a suitable model, you need to decide on the technical features and scope of use. Those who like to repair something at home with their own hands mostly use ordinary soldering irons, but they overheat the parts, resulting in the result of not repairing parts, but the opposite. This is the most important reason to leave the choice at the soldering station. The presence of a power supply makes work easy and simple thanks to the ability to change voltage and temperature.

Power plays a role, this is important when using refractory solders. Otherwise:

- high temperature – overheating of circuits;

- the tip is destroyed when exposed to high temperature;

- the heating part fails over time;

- overheating of board tracks;

- the quality of soldering decreases.

To avoid the above nuances, it is better to choose a station for lead-free soldering. You can also, which we talked about in the corresponding article!

Control type

A soldering station is one of the most important devices in electronics manufacturing. This indicates a high degree of need among people involved in this activity. The installation allows you to connect a pair of modules, which make it possible to solder with or without a contact, and you can also replace nozzles and tips.

To choose the right device, it is important to correctly determine the control method:

- digital (certain programs provide control over the heating of the tip, stability and accuracy in operation, rather than analog);

- analog (devices must be under constant monitoring, since high temperatures have a negative effect on the component parts of the device).

Main selection criteria

First-class adhesion of elements is the most important goal of a soldering station. To choose the right device you need to know the design and technical parameters:

- Heating element and its type. Today, the bulk of devices from which you can choose have 2 types - ceramic and nichrome. Ceramic ones heat up quickly, but can burst if heated unevenly; if there is a heat stabilizer, all this will not happen, it will control the temperature and the device will last longer. Nichrome quickly breaks down and is not suitable for frequent use. Costs significantly less than ceramics.

- The temperature adjustment range should be wider.

- Heating rate.

- Power. To select a soldering station based on power, you must initially know the area of operation of the device: phones, laptops, tablets or household appliances, etc.;

- Voltage; weight, size, shape, etc.

You also need to take into account such points as:

- global standards for lead-free soldering, which indicates equipment with a temperature of 250 degrees;

- The circuits are housed in a BGA chip package, making the device itself smaller and lighter.

What else is important to know?

When purchasing, craftsmen advise to also stock up on spare replacement tips. They all differ in shape and end area, which determines the result of the work itself. Also, in order to choose the appropriate design option, you need to know that a larger edge provides better heat exchange during soldering. In turn, the shape affects the type of elements that will be soldered, as well as accessibility to the soldering points and temperature.

Another important tip is that in order to choose everything correctly, you need to pay attention to the materials from which the soldering tips are made; they must conduct heat transfer well. In addition, you need to select equipment with easy replacement of parts in the event of failure of one of them.

The best manufacturers and models

Well, the last thing I would like to talk about is which soldering station is better to choose for home (hobbyists), work (electronics repair), as well as soldering plastic car parts.

First of all, let's talk about device manufacturers. The best today are the German company Ersa and the Chinese Quick. However, for those who like to repair electrical appliances at home, choosing soldering equipment from Ersa will not be the most rational decision. The fact is that the price of the equipment is quite high, so this option is better suited for professional use. At the same time, Quick has in its assortment budget soldering stations of more or less good quality.

Another popular company is Lukey. Many craftsmen and radio amateurs claim that this is the cheapest China, which breaks down quickly and can also cause a fire. Another part of the craftsmen recommends choosing a Lukey soldering station for beginner radio amateurs, because... Some equipment models are quite well made and, for their price, are the best option for a home workshop. To make your choice, we recommend checking out reviews on YouTube. You can find many video reviews of new equipment, which show the main functionality, equipment and disadvantages of certain soldering stations.

Still, the most popular inexpensive models are Lukey 702, 852D+ and 868. From Quick, the most often purchased are 202D ESD (for amateurs) and 702 ESD (for professionals).

A hot air station is suitable for repairing bumpers. A good option is Lukey 868, the operation of which is demonstrated in the photo:

Tips for Newbies

That's all I wanted to tell you about this rather complex issue. We hope you now know how to choose a soldering station and which one is better in 2017!

Soldering irons are available in almost every home these days. This is an ordinary and familiar tool, designed to solve various everyday issues related to soldering and minor repairs of household items. To restore more complex things, it is necessary to acquire higher quality equipment, such as soldering stations, which are in demand by both professional repairmen and home craftsmen. In this article we will tell you how to choose a soldering station and look at the existing types.

Soldering stations are widely used for small household jobs and electronics repairs.

Soldering stations are widely used for small household jobs and electronics repairs.

Types of soldering stations

There is a huge selection of stations, differing in several types. Read also the article: → "".

Contact units for sealing

Stations of this type in their design and appearance are similar to a soldering iron with an electronic unit for temperature control. Depending on the type of solder used, contact installations are divided into two types:

- for working with lead-tin compounds;

- for lead-free work.

The ProsKit contact soldering station is compact in size and easy to use

The ProsKit contact soldering station is compact in size and easy to use If with the first type, based on its name, everything is more or less clear, then the second has some features that require clarification. Such equipment is equipped with a heating element with a power of up to 160 W, which is explained by the need to create a high temperature. The regulator with which the stations are equipped also allows soldering using lead. Read also the article: → "".

Digital and analog soldering stations

Soldering machine STAYER 55370 is designed for soldering wires and working with electronics

Soldering machine STAYER 55370 is designed for soldering wires and working with electronics According to the operating principle of the control units, soldering installations are divided into two types. Heating control in analog stations is performed as follows:

- operation of the heating element continues until the temperature of the soldering iron core reaches the set value;

- When the core temperature drops below the set limit, the heater is connected and the tip is reheated.

The operation of the soldering iron is regulated by an electromagnetic relay controlled by a temperature sensor and electronics. The main advantage of analog installations is their affordable price. Among the disadvantages, one can point out the low accuracy, which sometimes causes the tip to overheat, which is why the soldered elements heat up too much, and the tip itself requires replacement.

In digital stations, the heater is controlled by a PID controller, the operation of which is checked by a special program embedded in the microcontroller, which ensures higher soldering accuracy compared to analog devices.

Induction installations with coils

The soldering iron tip in such stations is heated by an inductive pulse coil, which operates due to high-frequency oscillations that form eddy currents in the ferromagnetic coating. Heating is carried out to a temperature value called the Curie point, then the magnetic characteristics of the ferromagnet change and the heating of the tip stops.

Non-contact soldering stations for chip repair

Non-contact installations are used to repair microcircuits with a large number of pins, dismantle and replace their individual elements. Contactless stations are divided into several types:

- hot air;

- infrared;

- combined.

Tip #1: Hot-air soldering chambers with a hair dryer are classified as mounting devices that are not suitable for disassembling microcircuits with a large number of pins.

HY-850 Contactless Small-Size Hot Air Soldering Station

HY-850 Contactless Small-Size Hot Air Soldering Station For dismantling, special devices with a hot air gun are used; if a hair dryer is not available, then you can use a regular gas burner or an industrial hair dryer. At the same time, it is almost impossible to achieve high quality work, since a powerful jet of heated air can remove all parts from the board.

Stations of this model can be equipped with digital controllers, which naturally affects the cost of the device. To regulate the air flow, hair dryers are equipped with special attachments. The operation of infrared stations is based on heating a quartz or ceramic emitter. Such stations have the following advantages compared to hot air stations:

- it is possible to work with complex profile components;

- there is no need to replace nozzles for soldering a specific microcircuit;

- microcircuit elements are not blown away from the board by air;

- The soldering areas are heated evenly.

Combination soldering units combine both types of equipment: a soldering iron and a hair dryer.

Tip No. 2: You should know that infrared installations are equipment for work at a professional level and are more expensive. At home they are used extremely rarely.

Desoldering Devices

Installations of this type include a suction compressor, through which the solder is dismantled and dumped into a special container. An analysis of the most popular models of desoldering stations is presented in the table.

| Model | Characteristics | Advantages | Cost, rub. |

| HAKKO 474-74 | Power 100 W Demolition gun 816 (24V), Compressor 350-500 mmHg Art. | Fully antistatic dismantling unit | 54000 |

| Voltage 220 V/36 W Vacuum pressure 600 mHg Temperature range 200…450 °C Soldering iron power 90 W | Digital indicator Microprocessor control | 28000 | |

| Quick-201B ESD | Voltage 220 V/36 W Calorific value 90W Temperature 200-450°C Vacuum pressure 600 mHg | Resistance between tip and ground | 24000 |

| Element 948D | Power 90 W, 36 V, 400 kHz Vacuum pressure 600 mHg Compressor 350-500 mmHg Art. Suitable for lead-free solders | Availability of desalting pump | 15000 |

Element 948D soldering stations are low cost and easy to use

Element 948D soldering stations are low cost and easy to use Soldering Station Attachments

The most important accessories for any type of soldering station are special attachments that expand the range of use and functionality of the installation. There is a wide selection of different types of attachments that allow you to install or dismantle electronic parts with maximum efficiency.

Nozzles are produced in the following types:

- incisors - flat and sharp;

- elongated cone - straight and inclined;

- sting - blunt, thin, round, inclined;

- inclined incisors - at 30°, 45°, 60°;

- special nozzles for thermoelements.

Descriptions and approximate prices for some types of nozzles are given in the table:

| Type of nozzle | Manufacturer | Description | Cost, rub. |

| Tip ATP-8416 | China | Oxygen-free copper soldering tips with steel center and nickel-chrome outer plating. | 580 |

| Nozzle for hair dryer A1125 QFP10X10 | China | Universal attachment for various types of work | 550 |

| Tip ATP-8791 | China | For mounting and replacing the housing of a SIP 25L microcircuit | 2000 |

| Proconnect tip | China | For manual assembly of microcircuits | 540 |

| Cartridge tip AOYUE-WQ-4C | China | Replaceable soldering tip with single cut for precision lead-free soldering | 1700 |

Review of manufacturers and models of soldering devices: prices

Many manufacturers around the world manufacture soldering stations for various purposes. A brief overview of some models is presented in the table.

| Model | Country of manufacture | Peculiarities | Specifications | Cost, rub. |

| Analog-60A | Germany | ErgoTool Soldering Iron (60 W at 350 °C, 75 W at 280 °C) | Voltage: 230 V Power, 60 W Temperature display: no | 17000 |

| Dig2000A-Micro | Germany | Temperature control: “sensotronic” with LED display | Voltage: 230V 50/60Hz Power: 80W | 23000 |

| ICON VARIO 2 Modern (ICV2000-AXV) | Germany | LCD display with blue backlight | Voltage: 220-240 V, 50 Hz Power 2x160 W | 80000 |

| RDS80 | China | Low inertia ceramic heater | Voltage 220-230 V, 50 Hz Power 80 W | 11000 |

| HR100A | Germany | Combined soldering tool HybridTool | Voltage: 220-240 V 50/60 Hz Power 200 W | 230000 |

| ICON2 V + XTool-VARIO | Germany | Temperature control technologies SENSOTRONIC (PID), RESISTRONIC | Voltage: 110-120 V, 50/60 Hz Power 80 W | 85000 |

The HR100A soldering station has a very compact size and low cost

The HR100A soldering station has a very compact size and low cost Subtleties of choosing settings

The main criterion for choosing a soldering installation is to ensure high-quality soldering of parts, depending on the design features and technical characteristics. No less important points that require attention are:

- Heating element material. Modern soldering stations can be equipped with nichrome or ceramic heaters. The former are intended for rare use, as they do not have a long service life. Ceramic elements are sensitive to uneven heating, they are noticeably more expensive than nichrome ones, but they warm up quite quickly.

- Adjustable temperature range.

- Heating rate.

- Power. This parameter is the main one when selecting an installation. It is especially important when using equipment for soldering sensitive elements of tablets, navigators or smartphones.

- Voltage.

- Ergonomics (weight, main dimensions).

Regardless of the type of soldering station you choose, you should have several spare tips in reserve. Tips of various types have different shapes and tip areas - the larger the tip area, the better the heat exchange is achieved when working with it. The shape of the tip and its operating temperature affect the possibility of soldering some parts and elements.

FAQ

Question No. 1. Why is a hair dryer attached to the soldering station and is it possible to dispense with it in order to save money?

To perform work on dismantling microcircuits, a hairdryer must be used, preferably a turbine type - this affects the quality and speed of the work. Read also the article: → "".

Question No. 2. Which tips are best to choose as spare parts?

Unfortunately, tips from some manufacturers are not always suitable for soldering irons from other brands. NAKKO tips are considered to be among the best in quality, suitable for most common soldering stations.

Question No. 3. How important is the presence of a thermal stabilizer in the station kit?

Thermal stabilization is the most important property of soldering equipment. With this option, the temperature rises smoothly and quickly.

Question No. 4. How can you “save” a soldering iron tip when rosin burns on it?

If a black coating forms on the tip from burnt rosin, you can try to remove it with a sponge soaked in glycerin. When choosing a soldering iron, you should make sure that they are included in the equipment kit.

Question No. 5. Can hot air stations be used for all types of work on sensitive electronics?

Stations of this type are used to operate sensitive electrical appliances, smartphones, tablets and other modern gadgets. However, thermal air blowers cannot be used to work with large BGA chips.

Typical mistakes when choosing stations

Common mistakes when choosing a station include purchasing equipment with air pump rather than a hairdryer. The pump takes up too much space, which cannot but affect labor efficiency in conditions of limited work space. When choosing a station, you should pay attention to the length of the cord for connecting to the power supply. A short cord affects the mobility of the device and requires its installation near an outlet.

When purchasing a soldering station, you should take care of purchasing spare tips in advance. It’s better to choose not cheap nichrome ones, but ceramic ones - they have a longer “life expectancy”. By the way, the stings can be ordered from popular online stores, including those made in China.