Well-functioning plumbing is the main condition for the comfort of a modern person. But the toilet cistern may malfunction, so you need to be able to quickly fix the breakdown yourself. This will save time, money and nerves.

Construction device

The container for draining water into the toilet has the shape of a small tank that works on the principle of a water seal. Water is washed off in different ways: automatically by pressing a button or by moving a lever that opens free passage for water.

The drain mechanism successfully performs its functions thanks to important components of the fittings:

- The siphon shut-off membrane with a lid prevents water from escaping.

- To allow water to enter the drain tank, there is a special lever connected to the water pipe.

- The filling volume of the tank is controlled by a float. It works in conjunction with the lever and valve, connecting to them with a spoke.

- The overflow level tube is located to control the liquid level in the container.

The old-style toilet has features in the form of vertical movement of the piston under the action of the flush lever. The water supply is shut off from the side when the float reaches the specified level. Such models produce water intake and drainage with considerable noise.

Modern designs have a different arrangement of reinforcement; it is located closer to the bottom of the tank. The float rises along a vertical stem as the water fills. With the help of traction acting on the membrane, the liquid level in the tank is limited. Thanks to the bottom water supply, flushing and filling is carried out almost silently.

Characteristics of the main types of tank

In modern designs, the tank is most often attached to the toilet, connecting with it into a single whole. A separate arrangement involves building the container into the wall. Hanging options are also available. The connection to the toilet occurs through a pipe. The advantage of such drainage devices is the presence of a powerful pressure of supplied water, increased several times.

There are also tanks with differences in trigger mechanisms. Push-button models operating in one mode (one button) or two (two buttons) have become widespread. The device was created to save water. Under the action of one button, the container is completely emptied, the second mode is for using half the tank. In single-button versions, you can adjust the incomplete supply of liquid.

In suspended versions of the flush tank, levers or chains are used. Here, water is drained mechanically by pressing a lever, turning it, or pulling a chain.

According to the material of manufacture, they are distinguished:

- cast iron;

- faience;

- plastic.

The durability of cast iron containers is confirmed by the time of their service, but at the same time they look old-fashioned. The configuration of faience structures is varied. They are one with the toilet. The plastic built-in tank usually has a flat shape.

Depending on the types of drain tanks, breakdowns also occur, and appropriate methods for eliminating them are selected. Next, let's look at the most common problems.

Water flows from the tank into the toilet

If liquid from the container leaks onto the floor, then you need to pay attention to the condition of the O-ring that covers the connection between the bottom of the tank and the toilet shelf. If the fittings are worn out, they are replaced with new ones. When installing the gasket, it is better to lubricate it with liquid silicone, which will improve the wear resistance of the part.

The cause of the leak may also be loosening of the mounting bolts. Carefully tightening or replacing them will eliminate the leak.

If water constantly flows into the toilet, first of all it is necessary to determine the cause of the breakdown:

- A skewed lever caused the float to sink to the bottom of the tank. The resulting misalignment can be eliminated manually by moving the lever to its normal position.

- If the float is damaged or worn, water gets inside the bulb, preventing it from returning to its original position. Excess liquid has to be flushed down the toilet. You can replace the part of the drain mechanism yourself by temporarily cutting off the flow of water. You can prevent a malfunction by paying attention to the material from which the float is made. Floats made from stainless steel or special plastic are resistant to damage. For short-term sealing, the hole can be sealed by filling it with heated plastic. It will also help to temporarily seal the hole by wrapping the part with a plastic bag.

- Often the cause of leaks can be found in worn-out sealing gaskets and shut-off valves. If these consumables fail, they are replaced with new ones.

After completing the repair, it is important to pay attention to the position of the lever and the float in relation to it. If the components of the mechanism are installed incorrectly, they are adjusted.

There is no water flowing into the tank or it flows slowly

Dirt getting into the narrow part of the intake valve and completely clogging it is a common cause of such a malfunction. Before starting repairs, the tank is emptied of water, then the damaged part of the drain mechanism is unscrewed along with the lever and float. Taking a long needle or a piece of thin wire, clean the passage. The inlet pipe is also subjected to the procedure. To do this, first unscrew the valve. After checking that the breakdown has been eliminated, tighten the valve and install the valve in place.

Slow filling of the tank often occurs due to the fact that the pressure in the water supply system is low. Due to the weak water pressure, it is difficult for a membrane-type valve to cope with its functions. In case of such problems, it is better to replace the membrane with a rod.

Float repair and adjustment

The main elements of the drain mechanism include the float. It regulates the amount of water supplied to the tank and prevents it from overflowing. If earlier spherical structures often failed, then modern ones, similar in shape to a glass, suffer less from exposure to water.

The float is adjusted:

- by turning the lever, bringing it to the selected level;

- movement along the axis using a wheel.

If it is necessary to repair the float, the easiest way is to replace it with a new one. In order not to make a mistake in the choice, disconnect the failed element. Purchase from the store the same brand, suitable for a specific drain mechanism. The new one is installed as follows:

- After closing the valve, empty the drain container of water.

- Using an adjustable wrench, remove the pipe through which the liquid is supplied.

- The old float is removed and replaced with a new one.

- Adjust its position.

- The water supply pipe is put in place.

- Turning the valve allows the tank to fill.

You can return the float to working condition by first cleaning it from accumulated dirt.

Button repair

If the button malfunctions or gets stuck, you need to clear the element shaft of any blockage. A malfunction of the button’s functions, when the water does not drain after pressing, is associated with a broken connection between it and the drain valve. You can restore the connection with a piece of copper wire or by purchasing and installing a new one.

Problems with the operation of a two-button design are dealt with in a similar way. The sinking can be corrected quickly: by unscrewing the locking ring, raise the buttons to the appropriate level. Sometimes their position returns to normal after a few presses.

Other possible faults

There are other breakdowns in the operation of the drain mechanism:

- The reason for the failure of the lever is a violation of traction. Replacing an element with another involves purchasing a new one. For a while, the fittings can be replaced with thick wire, but it will not last long.

- If the tank is filled with excessive noise, open the lid and put the muffler tube on the fitting.

- If the liquid in the tank is constantly overflowing, you can avoid a malfunction by adjusting its filling level. The level of the edge of the overflow tube for lateral water supply should reach a mark ten millimeters below the hole. The tube is turned clockwise, setting it to the required height and locking by turning it counterclockwise.

A truly comfortable and convenient place to live will be the apartment or house in which the plumbing works well. In the event that there is a need to repair the toilet with your own efforts, you should first of all understand how it works.

Any toilet model includes a bowl (fixed to the floor) and a bowl (located above the bowl). Most often, the need for bathroom repairs arises due to breakdowns inside the cistern.

There are many known problems associated with tank repair. Repair of fittings is considered one of the most difficult and time-consuming. - this is a device with the help of which the tank is refilled with water after draining is completed, automatically controls the volume of water drained, as well as its overflow.

To understand what problem has arisen in the fittings, you need to know what elements does it consist of:

- a drain hole located at an angle;

- an overflow tube is connected directly to the drain hole;

- valve covers with tight rubber;

- mechanism required for filling;

- drain button mechanism.

Having the following problems with the tank at home, it’s time to think about repairing it or completely replacing it:

- (even a small trickle).

- The merging process does not occur immediately after pressing the button, but as a result of repeated repetitions.

- The process of filling the tank is very noisy.

If individual elements of the cistern fittings become unusable, you can only replace them, but it is important to ensure that all connecting elements fit 100% together. Otherwise, the repair will fail and this will entail a complete replacement of all fittings.

How to open the lid?

You can repair the flush and other mechanisms of the toilet cistern after disassembling it and removing the lid from it. Let's look at their varieties and learn how to open each of them.

With one button

To open it, you need to do the following:

- Using a flathead screwdriver, carefully turn counterclock-wise button ring;

- when the ring moves easily, you need to completely unscrew it without any tools;

- Having pulled out the ring, which resembles a cylinder, move the lid perpendicularly;

- in this position Easy to remove double sided clothespin, which holds the button;

- now remove the top part and repair the fittings;

- When the damage is fixed, reassemble the structure in the reverse order.

With two buttons

Complete the following activities:

- click on any one half of the button and feel with your finger the side hole in the other;

- by inserting a flat-head screwdriver into the found slot, carefully pull the button half and remove it;

- remove the other half;

- in the resulting hole you can see slotted screw that needs to be unscrewed;

- move the lid gradually until it reaches a perpendicular position;

- remove the double-sided clothespin;

- place the released lid on a flat surface so that it does not break;

- after repair work, reassemble everything, observing reverse steps.

Find out more about one or two and repair their specific breakdowns.

With pull rod

There are models where water is drained not by pressing a button, but by lifting up the rod, which is located in the center of the lid. You can remove the top part of the tank when you push back the small ball located at the end of the rod. After this, the lid will lift off easily.

Built-in toilet cisterns

The design of such tanks is very simple, unlike those listed above. It has only a small drainage device, which is a block. If a wall-mounted tank breaks, only it can break.

You don't have to break down walls to get it out. You just need unscrew the wall button and remove the drainage device through it. After repair, it is easy to return it to its place through the same button hole.

How to disassemble the drain mechanism?

The disassembly scheme for the drain mechanism will not cause much trouble or difficulty if you adhere to some recommendations in this regard:

- Remove the reservoir cap.

- Look, does the locking mechanism work well?. The float should be no more than half in water, and the water should not be too close to the drain tube.

- Before starting repairs, drain the water and limit its flow into the tank.

- Determine the type of bulb (valve bulb or float bulb).

- You can unscrew the float bulb if additionally hold by the stem.

- The valve bulb is covered by a plastic ring that holds the trigger mechanism. You should grab the ring and turn it counterclockwise, freeing the bulb for inspection.

- You can remove the described device from the rods by pressing on one of the clamps (there are four in total).

- If the pear has uneven spots, cracks or rust, it must be replaced.

- When replacing one device with another, make sure that their dimensions are completely identical.

By following all the above instructions, you will never need to call a specialist, because you can do all the work yourself.

Adjustment of individual elements

To install a new water filling system, You will need the following tools:

- plastic ruler or metal tape measure;

- adjustable wrench;

- spanners;

- recently purchased fittings components.

Water can flow into the tank. If we are talking about a lateral connection, for repairs you need to perform the following steps:

- Set the diameter of the water intake pipe.

- Choose the system that is needed for your model. This is quite simple to do - you need to remove the lid from the tank and see what kind of fittings are in it. After that, buy the same one for sure.

- After the entire structure has been purchased, you can install new water intake fittings.

- Shut off the water supply to the toilet.

- Open the lid and drain the water completely.

- Remove the old fittings. This can be done after you unscrew the nut located on the flexible hose with a wrench. At the same time, be sure to support the entire structure.

This event One person can do it - the main thing is to work harmoniously with both hands.

In the case where the water comes from below, you will need to struggle a lot to unscrew the nut. This can be done only with improvised materials or by first shortening a standard wrench:

- Carefully inspect the used gasket. If it has no visible damage or irregularities, it can be reused for a new structure being installed.

- New fittings must be positioned so as not to interfere with the operation of the drain system, and also do not touch the walls of the tank itself.

- Connect the water.

- Check that the work has been completed correctly.

Setting up the drainage system

By ensuring your drainage system is working properly, you can save a significant amount of money that would otherwise be spent on excessive water consumption. To begin repairing a flush cistern without the help of a technician, all stages of work should be performed in strict sequence, without missing possible breakdowns and shortcomings.

- Get rid of float mechanism failures. It is quite easy to understand if there are problems with it. The main indicator is that the tank is constantly filled with water, and it immediately flows into the toilet.

There are several reasons leading to this process:

- poor intake valve condition(in some cases it fails due to high water pressure);

- displacer malfunction(as a result of prolonged use, the float may crack and fill with water);

- lever misalignment(it should be horizontally 20 mm below the hole through which water is drawn).

- Eliminate constant water leaking into the toilet. Most often, this problem occurs due to the expiration of the siphon membrane. It needs to be replaced with a new one.

To do this, drain the water, remove the siphon, replace the old membrane with a new one, put the siphon in place, attach it to the lever and tighten the fastening nut.

To fully adjust the drain mechanism of the toilet cistern, if it is broken, it is necessary to eliminate all these faults.

Do-it-yourself replacement of fittings

Replacement work should begin with turning off the water supply and draining it. After this, the supply hose is removed and the tank itself is unscrewed. Then the old fittings are pulled out and the water supply valve is unscrewed.

The final stage of repair is installing new fittings and securing the bowl to the toilet. Checking the correct position of the float and the normal functioning of the sealing washer located on the water supply hose. Pay special attention to the nut that tightens the hose. There is no need for extra effort in twisting it.

Video about repairing and replacing toilet cistern fittings with your own hands will help you better understand the issue:

How to remove the tank completely if repair is impossible?

If the toilet tank cannot be repaired, it should be carefully replaced- but how to do that? You need to act in a certain sequence:

- Stop water supply. Using a Swedish adjustable wrench, disconnect the water line.

- Unscrew the drain button.

- Remove the cover.

- Unscrew the two screws that attach the bowl to the toilet (they are located at the bottom of the tank).

- Install a new one in place of the old gasket. This will help avoid possible leaks in the future.

- Attach a new tank to the toilet, strictly following the reverse sequence of actions.

The tank must be installed level, otherwise it will either crack or leak. The bolts are screwed to the toilet gradually to avoid distortion.

If you have problems with the toilet no need to panic and immediately contact the specialist. Having a few screwdrivers and pliers at home, as well as listening to the recommendations of experts, you can do all the work yourself, even if this is your first time.

If you are installing new plumbing equipment in your home, including a toilet, be sure to pay attention to the correct and reliable connection of all components of the equipment. The uninterrupted operation of the device depends on the tightness of the connections of the nodes.

A properly functioning toilet brings a high level of comfort to your home. However, any plumbing fixture can break. Troubles occur especially often in older devices. Poor water quality has a destructive effect on the components of the toilet flush system. Hard water with foreign impurities gradually damages equipment. Every homeowner should know how to fix a toilet flush tank.

Tank drain device

At first glance, the toilet flush system looks quite simple - it is a earthenware or plastic container that is automatically filled with water, which is then used to flush away sewage.

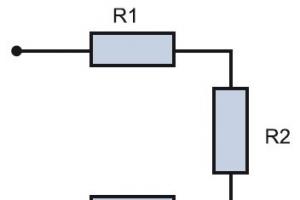

Main components of a toilet cistern

- Fittings responsible for filling the tank with water

- A mechanism that initiates draining water from the tank (rod/lever or single/dual mode button).

Such basic elements of the cistern are found in almost all models, even in old devices from the Soviet period. They may differ in materials and appearance, but their main tasks: control of intake and initiation of water flow remain the same.

The main types of toilet flush tank design are the float mechanism and the flush column.

The figure below shows the structure of a classic flush tank with a float mechanism. Such internal fittings were equipped with flush cisterns of the Soviet period and continue to be used today on devices with a side flush lever.

All main components of the cistern are interconnected. Damage to one element can cause the entire equipment to fail.

Repairing the float mechanism

One of the most common breakdowns of toilet cistern mechanisms is the constant flow of water. The reason is a malfunction of the float device, which should turn off the water supply to the container when it reaches a certain level.

The main reasons for this behavior of the float mechanism may be the following factors:

- breakdown of the water inlet valve into the tank;

- incorrect position of the lever responsible for turning on the drain mechanism;

- incorrect float operation.

On older models, inspect the float. This is a hollow plastic container. From prolonged use, cracks may form in it. Then water from the tank penetrates into the float and it sinks. This type of unit is the easiest to replace - the float is usually attached to a screw with a nut.

In modern models of flush tanks, there is no hollow plastic float. The inlet valve is closed by another unit - a drain column, which is easier to replace entirely. Some models of drain columns have an adjustment mechanism that determines the filling level of the tank and the amount of water discharged.

Checking the operation of the tank inlet valve

- To understand how correctly the valve closing mechanism in the tank operates, examine the lever located next to the valve.

- Drain the water and watch the tank fill.

- Move the rocker arm.

- When the lever is placed in a certain position, it should close the inlet valve. If the lever is bent during operation, correct its configuration.

- If the unit that allows the lever to move is jammed, replace it.

Another reason for constant drainage may be intake valve malfunction. In this case, despite the proper operation of the float mechanism, the tank is constantly filled with water and constantly drained. Valve failure can occur due to surges in water pressure in the pipelines. In this case, the valve is easiest to replace - it is a fairly simple device that can be found in almost any hardware store. Remove the valve and purchase a similar one. TO ok, you can read in our article.

A constant flow of water from the tank into the toilet can also occur due to cause of exhaust valve failure. This device is not worth repairing; it is better to replace it entirely with an identical one. If, after dismantling the outlet valve, it is discovered that the rubber siphon gasket has worn out, it should be replaced. This part is not expensive.

What to do if the toilet cistern is noisy?

The sound of water filling the cistern can cause discomfort in your household. This problem usually occurs in toilet tanks with an overhead water supply. This problem can be easily fixed in two ways.

- In some models of tanks Inlet diameter can be adjusted. Reduce its cross-section. The tank will fill more slowly, but will not make annoying sounds.

- You can also have several modify the internal fittings of the tank:

- find a plastic or rubber tube about 30 centimeters long;

- install it so that one end is put on the inlet hole, and lower the other to the bottom of the tank.

Now the water will not create a “waterfall”, but will silently fill the tank through the tube.

Replacing bolts in a leaking toilet

Most toilet cistern models are attached to the shelf using bolts that go through the bottom of the container. Metal bolts are susceptible to corrosion and may rot after a while. In this case, water will seep through the holes and drip onto the floor.

Bolt replacement algorithm

- Close the water supply valve to the tank.

- Drain the remaining water from the toilet tank.

- We dismantle the inlet valve of the tank.

- We remove both connecting bolts securing the tank to the toilet shelf.

- The tank is located on a rubber cuff. Raise the tank and remove the cuff. If necessary, we replace it.

- We clean the joints and free them from dirt.

- We reassemble the equipment in the reverse order with the insertion of new bolts. When tightening the bolts, do not use excessive force to prevent the sanitaryware from bursting.

- We check that the tank is working properly and that there are no leaks.

No water flows into the cistern

There are three types of faults that could be causing your toilet tank to stop filling with water.

- At the initial stage check the condition of the supply flexible hose. To do this, you need to turn off the water, disconnect the hose from the basque body and open the shut-off valve slightly, pointing the end of the hose into the toilet. Water will flow from a working hose. If water does not flow, the flexible supply hose must be replaced with an identical one.

- Also, the reason for the lack of water supply may be inlet valve clogged. It can become clogged with impurities contained in tap water. You can try to clean the valve hole with a thin, long object.

- The inlet valve may, for one reason or another, completely fail.. In this case, if cleaning attempts are unsuccessful, the valve must be completely replaced.

Changing the internal fittings of the drain tank

Faults in the tank fittings can occur like an avalanche. In this case, you can not change worn parts, but replace the entire internal fittings of the drain tank. Examine the design of the fittings in your tank. Drain tanks are available with various designs of internal fittings. In particular, toilet tanks differ in the type of water supply - flexible hose can be connected to the top, side or bottom of the tank.

Let's figure it out how to replace internal fittings on a tank with bottom water supply. To carry out this work, a minimum set of tools is required: wrenches and pliers.

- Close the shut-off valve.

- Remove the water drain button. It can be unscrewed or fixed with clips.

- Remove the top cover of the drain tank.

- Unscrew the fastening of the supply hose to the drain tank and disconnect it.

- Rotate 90 degrees and remove the top half of the drain column.

- We unscrew the bolts securing the flush tank to the toilet.

- Place the flush cistern on the toilet.

- Unscrew the nuts securing the inlet valve and drain column, and dismantle the remaining part of the column.

- We install the internal fittings of the tank and assemble the equipment in the reverse order.

Installing a new speaker

- A drain column is placed in the empty tank. It is located above the outlet.

- The drain column is fixed at the bottom with a threaded cuff.

- An inlet valve with a fill adjustment mechanism is located above the inlet.

- The inlet valve is fixed with a threaded cuff from the bottom of the tank

Eliminating leaks in the drain tank

To eliminate leaks in the tank, you must carefully check all threaded connections. You can put pieces of toilet paper or paper napkins under them, on which even the smallest drops will be visible. If leaks are detected, the pipe connection is reassembled using additional sealing tape.

Prices for sealing tape

sealing tape

Replacing the drain tank

Any internal components of the toilet cistern can be replaced. But this can only be done if you find an identical device.

Every year, tanks with new internal fitting designs appear on the market, which may not be compatible with previous generations. In this case, after shopping around, you can decide to buy a new tank. It is easier to solve this issue if in your toilet the cistern and toilet bowl are made as separate structural elements. There are models of plumbing equipment in which the cistern and toilet bowl are made as a single unit.

The toilet tank must also be replaced if cracks are found in the sanitaryware. In this case, no repairs will help the matter; the destruction process is irreversible. A temporary measure may be to dry the tank and apply a thick layer of silicone sealant to the area of the crack.

As you can see, the cost and duration of repairing a toilet cistern depend on the nature of the damage. Some faults can be eliminated by replacing elements of internal fittings. If cracks are found in the tank body, or it is impossible to purchase suitable fittings, you will have to replace the flush tank, and possibly the entire toilet set.

In a home where there is plumbing, sooner or later a situation may arise where it malfunctions. However, you should not immediately contact plumbers, since repairing the drain tank yourself should not cause you any difficulties.

Toilet design

When starting repair work, you need to know exactly the structure of the toilet, which is quite primitive. The equipment has two parts: a bowl mounted on the wall or floor and the cistern itself, located on top.

The basis of the tank's operation is a hydraulic shutter, which is activated by pressing a button or drain lever.

Under the cover of this device there is a float, a seal and a lever system, due to which water flows, accumulates and drains in the tank. Restriction of water access is ensured by a special valve that shuts off the water at a certain level.

Preliminary preparation

In order to carry out repair work, it is necessary to remove the lid from the tank. This step should be performed with extreme caution, since this element is not sold separately and if it is damaged, you will have to replace the entire tank. Pay attention to how it is attached to the tank, since the mounting system largely depends on the manufacturer.

Then turn off the flow of water into the tank without making sudden movements, since a worn locking mechanism can easily be damaged, and then it will not be possible to avoid a flood.

Most likely problems

The cistern suddenly becomes faulty and causes a lot of trouble. In order to avoid major consequences, it is necessary to immediately eliminate minor problems when they occur.

The most likely breakdown is the constant filling and leakage of water into and out of the tank. This may happen in the following cases:

- If the float is skewed;

- The mechanism holding the float has become loose;

- When gaskets, seals or shut-off valve wear out.

A malfunction of this nature does not require tools to correct it. Remove the lid from the tank and adjust the float by hand. If the cause of the breakdown was misalignment, then the water should stop flowing randomly; if this does not happen, also correct the shut-off valve, the misalignment of which may also be the cause of the breakdown.

Relaxation of the mechanism

This breakdown occurs when water fills the tank, but does not stop flowing, but begins to flow out of it. To determine the cause, the inlet valve must be raised all the way up. When the float mechanism is working, the water supply must stop, otherwise the float mechanism must be replaced.

Worn valve, gaskets or seals

- The wear of elements is quite easy to determine - by lightly pressing the valve. If water begins to leak at this time, the worn parts must be replaced.

- The cause of the problem may be wear on the float, or the appearance of a hole in it through which water leaks. Repair is carried out by replacing it. If you don't have the necessary parts, you can try to temporarily fix the problem by using heated plastic to close the hole. Alternatively, you can place a plastic bag over the float and secure it around the post.

- New models of toilets are equipped with a membrane valve in the flush tank, the function of which is to prevent the penetration of dirt and damage. However, the service life of the membrane is quite short. To get rid of this malfunction, you can imitate a membrane made of thick rubber, which is cut to the shape of the worn element.

- Another defect may be the filling of the tank with excessive noise, or a malfunction of the water release lever.

Video

Check out the diaphragm valve replacement technology:

Breakage of the trigger lever

The cause of this malfunction is a damaged rod, which simply needs to be replaced with a new one. If the part is not at hand, you can make a rod from wire.

However, this will not get rid of the problem, and at the first opportunity you need to buy this part in the store.

Noisy filling of the tank with water

This problem is not so much dangerous as it is unpleasant, especially at night. Especially if the bedroom is located close to the bathroom. To solve this problem you can proceed in two ways:

- The first option is to fix a flexible plastic pipe to a float valve. The muffler is mounted at the beginning of the float valve perpendicular to the water level, with the lower end lowered into the water. This will help the water flow into the tank below the level, which will significantly reduce the noise level.

- Another solution would be a stabilizing float valve.

The noise level is reduced due to the fact that water passes through a stabilizing chamber, equalizing the water pressure on both sides of the piston.

In order to reduce problems with the drain tank, it is worth carrying out a preventive inspection of parts to ensure they are in good condition.

Video

In the following video you will see how to change the fill valve:

The design and operating principle of the drain tank are quite simple, so there are rarely any difficulties in repairing the device.

If the cistern breaks down, water does not flow onto the floor, and there is no threat of flooding to the neighbors below. Such malfunctions seem insignificant, but this is only until the bill for payment for water supply services arrives.

If a meter is installed, then any malfunction of the tank can become a problem! Therefore, the smartest solution is to eliminate it immediately, without waiting for trouble.

Minor difficulties sometimes occur only with improved modern models; in such cases, it is worth contacting specialists. Basically, almost any repair of a toilet cistern can be done with your own hands.

The design of a toilet cistern is quite simple, and almost anyone can cope with its repair, because... you don't need any special skills for this

In many ways, cisterns of different designs are similar. The main difference is the installation method:

- Hanging tanks. Structures of this type are attached to the toilet bowl at a low height and connected using a pipe.

- Compact toilet cistern. The compact flush cistern is attached directly to the toilet bowl without connecting pipes.

- Built-in tank. Constructions of this type are installed in the wall and are used with wall-hung toilets.

Regardless of the model, the designs of the cisterns are very similar. Modern devices are convenient because they can be repaired without disassembling the modules and replacing them entirely

Water is supplied to the cistern either from below or from the side. The side feed device is most often found in domestically produced toilets. Its advantage is its relatively low price, which affects the cost of the entire toilet as a whole.

Bottom water supply is often found in modern domestic and imported designs. These are usually slightly more expensive models.

For draining, mechanisms of various types can be provided: buttons, rods, levers, chains. The most common option is a button.

It can be located in the upper part of the structure, and in models with a hidden tank - on the wall. To drain the water, just press on it.

Models with a push-button mechanism can only be disassembled after removing the button. How to remove the lid from a tank of this design is shown in detail in the video:

Buttons in which the water is completely drained after a short single press are called automatic.

Those in which water is drained only while the button is pressed are mechanical. The former are more convenient to use, while the latter allow you to save water when flushing the toilet.

There are single- and dual-mode push-button flush mechanisms. Models with two buttons provide the ability to drain only half the volume of the tank.

However, there are designs with one button, which in the same way can drain either the full volume of water or half. If the push-button mechanism is equipped with a special auger that forces the water to rotate when flushing, then the toilet bowl is washed more efficiently.

Mechanisms with two buttons are a little more expensive, but the overpayments pay off, because draining in economy mode can reduce water consumption by 20 cubic meters. in year

Adjusting the volume of collected water

If desired, you can easily regulate the amount of water drawn into the tank. This is necessary if the toilet does not flush well or there is too much water and there is a need to reduce its volume.

To change the filling volume, you need to remove the tank cap and follow simple steps. But before you start making adjustments, you first need to understand the structure of the tank.

The video below will help with this:

Option #1 – for side feed systems

Such mechanisms are equipped with a lever made of thick metal wire. It connects the valve and the float. To raise or lower the float, you need to bend the wire lever slightly.

After this, you should make sure that the required amount of water is filled into the tank. If not, bend the wire a little more. By lifting the lever, you can increase the volume of water; by lowering it, you can decrease it.

This option is only suitable for those tanks that use metal in the float system.

Many modern models use plastic parts instead of metal parts. Such levers cannot be bent, but the float itself can be moved along their axis using the fastening screw provided by the design.

The float can be secured with a thread or a latch. If a latch is used in the design, then it is pressed out. To increase the volume of water in the tank, the float is moved closer to the valve body.

As a result, the length of the lever decreases. If it is necessary to reduce the water level, the float is moved further from the body.

This is the simplest design of a flush tank with side water supply. Brass wire is used as a lever. By slightly changing the angle of its inclination, you can reduce the amount of water in the tank. If your home has a meter installed, this is a great way to save on utility bills.

Option #2 - in tanks with bottom supply

If the design has a bottom water supply, it can be adjusted even more easily than a system with a side supply. The mechanism has a special water level limiter connecting the valve lever and the float. It can be lengthened or shortened.

The float on the limiter is secured with a thread. To adjust the water level in the tank, you need to change its height using a plastic nut.

The main advantage of bottom-feed designs is their ease of installation and maintenance. When repairing or replacing, problems arise extremely rarely

How to diagnose problems?

If the flush tank is faulty, it quickly becomes obvious: water either leaks into the toilet bowl or begins to drip onto the floor. Sometimes it happens that the container does not fill.

No matter how cutting-edge and complex the design of the tank, breakdowns occur in the same way in all models.

External leaks are not always immediately visible. It happens that water drips out for weeks, but its amount is so small that the damp areas are not noticeable. Then the leak can be identified by the appearance of red spots and streaks of rust.

If they are, it is worth disassembling the tank and establishing the cause of the breakdown.

If there is no coarse filter, dirt and rust particles constantly enter the tank. They accumulate in the container and can damage the internal mechanisms of the structure and cause breakdown

Normally, the tank is filled to a predetermined level, and the rubber bulb is pressed to the drain hole, reliably closes it and is held in this position by water pressure. When you press the release mechanism, this bulb rises and opens the drain hole.

The rubber bulb must be constantly filled with air. To prevent water from getting into it, the design includes a special guide tube. It ensures the correct position of the pear in the “saddle”.

If the integrity of the bulb or tube itself is compromised, the mechanism fails.

This is what the rubber bulb of the tank should look like if it is in working order. It should remain elastic and fit well to the saddle.

The first thing to do after disassembling the tank is to inspect the bulb. If it has lost its elasticity and cracked, then this is where the cause of the leak lies. Worn rubber cannot cover the drain hole well; water leaks into cracks and gaps.

Rubber products of this type cannot be repaired, so the bulb just needs to be replaced.

If everything is fine with it, you need to make sure that no particles of dirt and rust get under the rubber, which can also interfere with the normal operation of the pear.

There are cases when the leakage problem can be solved by simply cleaning the tank. If it turns out that dirt has accumulated under the rubber bulb, it can be removed with a regular sponge. Often this is enough to restore normal operation. For preventative purposes, it also makes sense to wipe the walls of the container with a rag and remove plaque.

If the bulb is in order, then you should continue to inspect the toilet tank in search of the cause of the leak.

The tank does not fill if:

- the supply hose is faulty;

- The inlet valve of the float mechanism is worn out.

Water may leak out if:

- the gasket between the tank and the toilet is worn out;

- A leak has appeared at the installation site of the connecting screws.

Internal leaks occur when:

- the overflow tube is not adjusted;

- valve is faulty;

- The float has failed.

All these components should be carefully checked and damaged parts repaired, adjusted or replaced. How to disassemble the tank and find these elements is shown in the video:

Problem #1: Water does not flow into the tank

How can you fix a toilet cistern if water stops flowing into it? It is not difficult. First of all, check the supply hose. It is disconnected from the tank and one end is lowered into a container.

If the water does not flow, you can simply buy and install a new hose.

Most often, the problem lies in a clogged narrow part of the valve. For repairs, it is enough to empty the tank, turn off the water and unscrew the assembly consisting of a valve, lever and float.

When the parts are removed, a hole will open through which the container is filled. It is very often clogged. You can clean it with a regular needle or wire.

To carry out complete cleaning, you need to remove the valve from the inlet pipe and wash off any remaining dirt with water.

Sometimes the cause of a breakdown is a tiny piece of scale caught in the hose or dirt. You can try rinsing or cleaning it

Problem #2: External leaks

If an external leak appears, you can repair the toilet yourself and not call a repairman. Typically, problems arise due to a loose seal between the toilet bowl and the tank, or if the seals under the screws are worn out.

In the first case, it is enough to remove the tank, check the gasket and, if it has become too hard or cracked, replace it.

It happens that the reason for such a leak is trivial - the gasket is installed incorrectly. Then it’s enough just to put it in place, or better yet, change it.

If a leak appears at the connecting screws, they need to be unscrewed and the rubber seals replaced. To do this, it is not even necessary to remove the tank itself.

When choosing new seals, it is better to give preference to cone-shaped ones rather than flat ones. They adhere much more tightly to surfaces.

When tightening the screws after replacing the seals, it is important to ensure an even distribution of forces to prevent distortions, otherwise a new leak may appear. To do this, tighten the screws little by little and one at a time.

Problem #3: eliminating internal leaks

How to fix the tank if water flows into the toilet bowl? First, you should check that the overflow tube is set correctly. You need to lift it a little and see if water flows into the tube.

If yes, then the float valve needs to be repaired. If not, you need to adjust the lever.

Valve problems can be caused by debris. You just need to remove it from under the gum.

If the rubber is worn out, you can simply turn it over to the other side, but it is better to change it immediately. If the valve is broken, you will have to replace it with a new one.

We offer video instructions for replacing the cistern fittings:

Problem #4: tank noise when filling

The noise when filling the tank with water cannot be called a breakdown, because... all mechanisms are working properly. However, loud sounds can be very annoying and interfere with proper rest.

Most often, the tank becomes loud immediately after draining the water, then the noise becomes less.

Solving the problem is very simple. To do this, put a small piece of rubber or plastic tube on the nozzle of the locking mechanism.

The length should be such that the tube reaches the bottom of the container. After this, the tank will make much less noise.

In addition to this device, there are other ways to get rid of noise when the tank is operating. The radical solution is to replace the conventional float valve with a stabilizing valve with a special chamber. In this case, you will be able to forget about noise forever and relax in comfort.

Repairing a toilet cistern is a simple procedure. To fix all the problems with your own hands, all you need is time, desire and the simplest tools.

However, sometimes difficulties arise with diagnosing breakdowns or repairing themselves. In this case, it is better not to experiment and call a plumber.